A kind of organophosphate zinc-silane composite passivation film modified zinc metal negative electrode and its preparation method and application

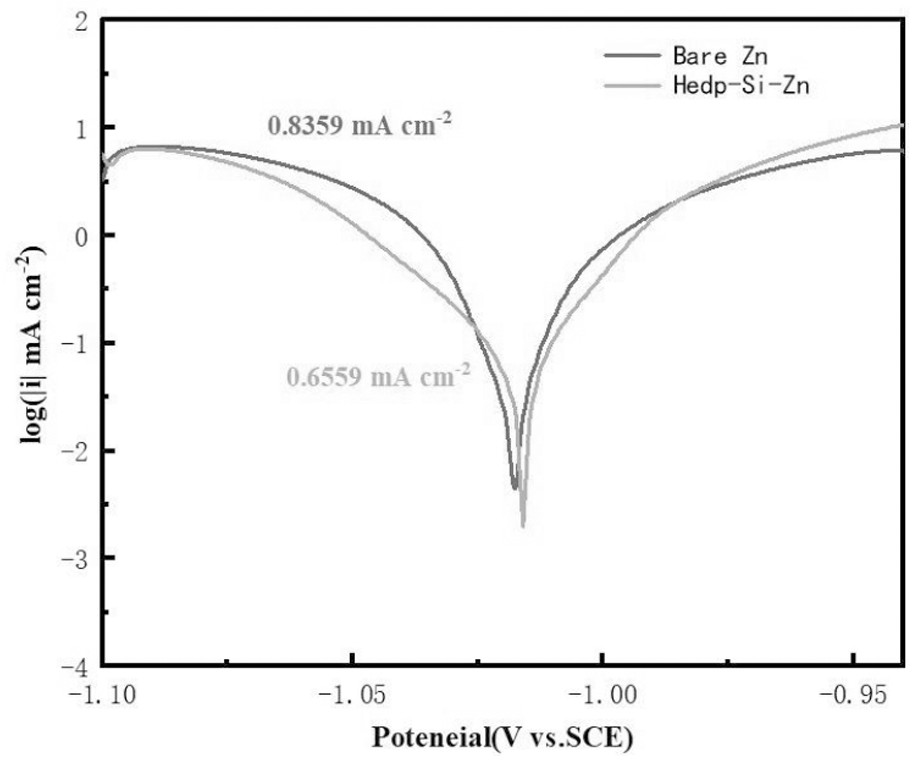

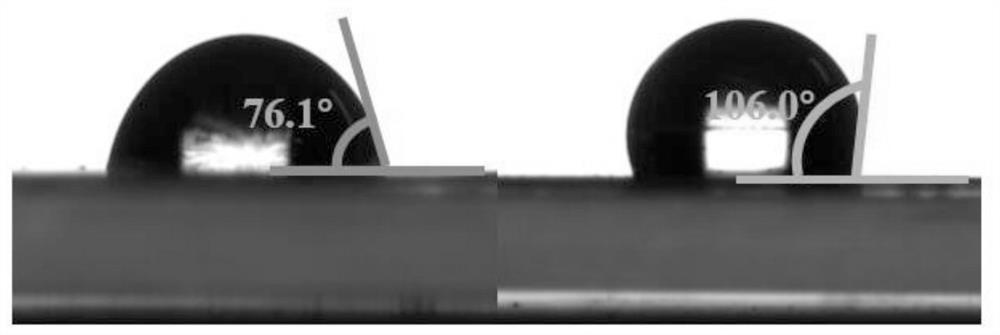

A technology of organic zinc phosphate and zinc metal, applied in the direction of negative electrode, electrode manufacturing, active material electrode, etc., can solve the problems that hinder the development and application of aqueous zinc-ion batteries, the decline of Coulombic efficiency and cycle stability, and the attenuation of battery capacity. Achieve the effects of inhibiting hydrogen evolution corrosion, enhancing desolvation effect, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

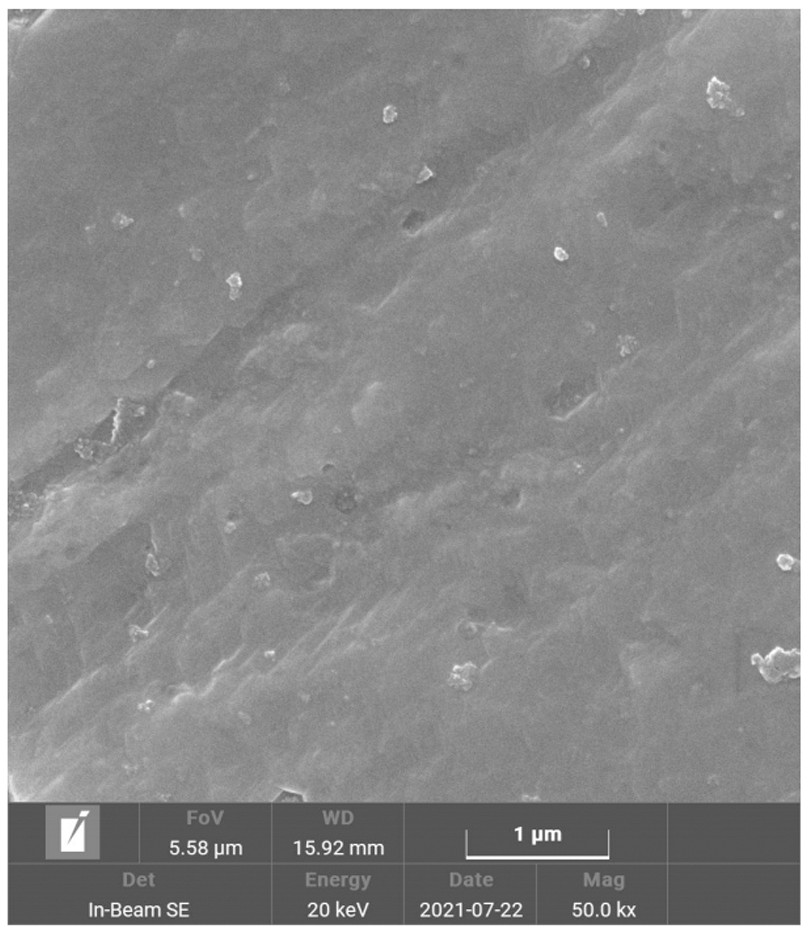

Method used

Image

Examples

Embodiment 1

[0040] First prepare the zinc metal disc to be modified: take a commercial zinc sheet with a certain size and a thickness of 0.1mm, and then use a punching machine to punch it into a disc with a diameter of 16mm, and then punch the zinc sheet after punching Use a heavy object to press the surface until it is flat, and then ultrasonically clean the flattened zinc sheet with ultrapure water and ethanol for 10 minutes, and then put it in a vacuum oven at 30°C to dry it for use.

[0041] Weigh 0.27g of hydroxyethylidene diphosphonic acid into a beaker containing 50mL of distilled water and stir to fully dissolve it, which is recorded as solution A. Weigh 0.2g of methyltriethoxysilane into a beaker containing 10mL of absolute ethanol Stir to fully dissolve it, record it as solution B, slowly add solution B dropwise to solution A under rapid stirring conditions, mix well, place it in a water bath at 75°C, heat for 3 hours under slow stirring conditions, and take it out after 3 hours ...

Embodiment 2

[0043] This embodiment carries out similar parallel test with embodiment 1, wherein the concentration of hydroxyethylidene diphosphonic acid aqueous solution is 2.5g / L, other preparation methods are exactly the same as embodiment 1, obtain organophosphate zinc-silane composite passivation film Modified zinc metal anode.

Embodiment 3

[0045] The present embodiment carries out similar parallel test with embodiment 1, 2, wherein the mass concentration of methyltriethoxysilane organic solution is 8g / L, other other preparation methods are exactly the same as embodiment 1, obtain organophosphate zinc- Silane composite passivation film modified zinc metal anode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com