PTFE microfiltration membrane and hydrophilic modification method of PTFE microfiltration membrane

A hydrophilic modification, PTFE technology, used in chemical instruments and methods, membranes, ultrafiltration, etc., can solve problems such as damage to the molecular structure and morphology of the membrane surface, environmental pollution of harmful waste liquids, and blockage of membrane pores, and achieve good industrial performance. Application prospect, improve separation efficiency, improve the effect of contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

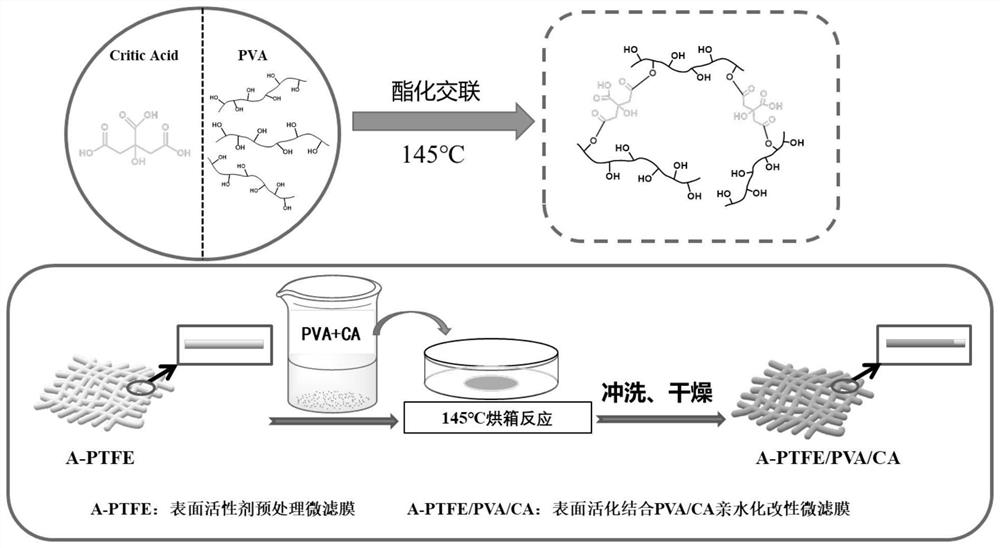

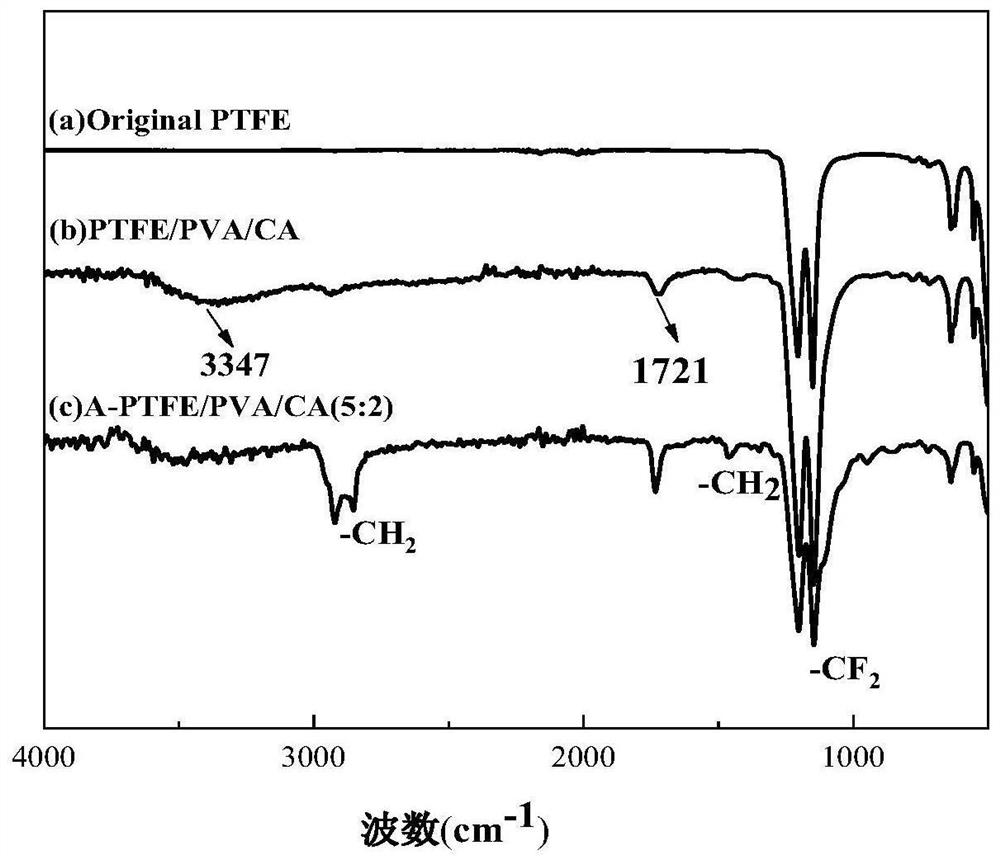

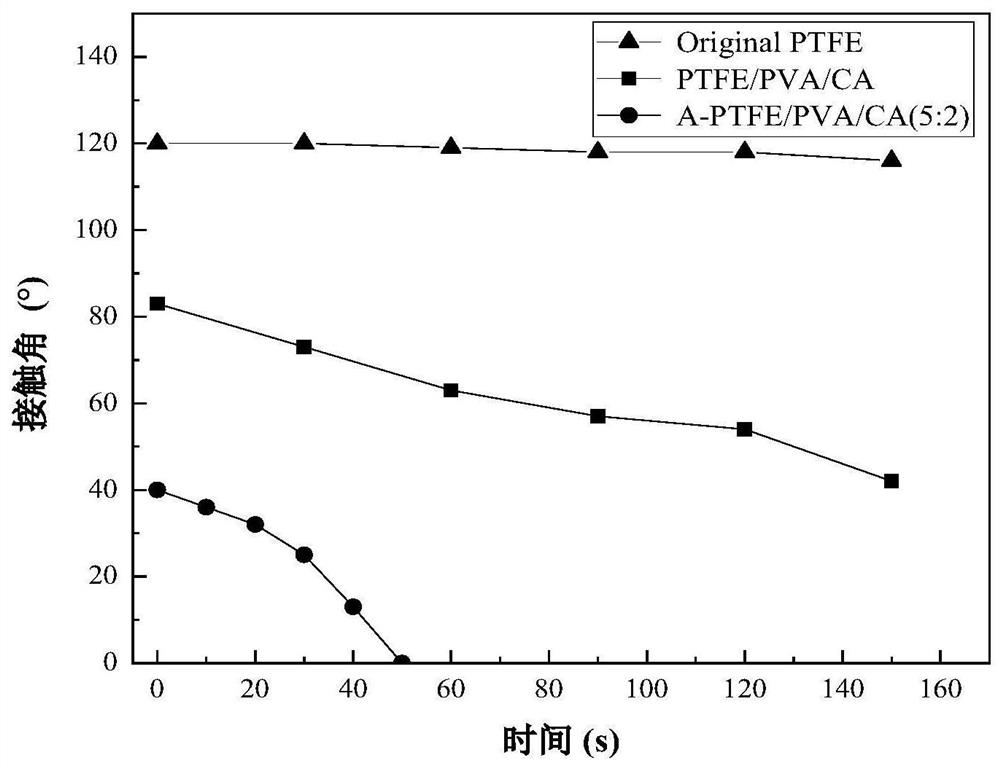

[0038] A method for hydrophilic modification of PTFE flat microfiltration membranes, prepared from the following components in parts by weight: 100 parts of ethanol solution, 0.5 parts of polyvinyl alcohol, 0.2 parts of citric acid crosslinking agent, and 99.3 parts of deionized water solvent , wherein the weight fraction of polyvinyl alcohol is 0.5%, and the ratio of polyvinyl alcohol and citric acid is 5:2.

[0039] The modification method of the above-mentioned hydrophilized modified PTFE microfiltration membrane comprises the following preparation steps:

[0040] Step 1: Pre-wet the cleaned PTFE microfiltration membrane in absolute ethanol for use;

[0041] Step 2: Dissolve polyvinyl alcohol in deionized water by stirring for 3 hours at 95°C, add crosslinking agent citric acid after cooling, and stir evenly to form a hydrophilic pre-reaction solution; microfilter the pre-wetted PTFE obtained in step 1 The film was placed in the cross-linking pre-reaction solution for soak...

Embodiment 2

[0044] A method for hydrophilic modification of PTFE flat microfiltration membrane, prepared from the following components in parts by weight: 1 part of polyethylene glycol monolaurate, 99 parts of ethanol solution, 0.5 part of polyvinyl alcohol, citric acid cross 0.2 part of joint agent, 99.3 parts of deionized water solvent, wherein the weight fraction of polyethylene glycol monolaurate is 1%, the weight fraction of polyvinyl alcohol is 0.5%, and the ratio of polyvinyl alcohol and citric acid is 5:2.

[0045] The modification method of the above-mentioned hydrophilized modified PTFE microfiltration membrane comprises the following preparation steps:

[0046] Step 1: Dissolve the surfactant in absolute ethanol and disperse it evenly at 1000r / min;

[0047] Step 2: Completely immerse the cleaned PTFE microfiltration membrane in the surfactant solution obtained in step 1 for 30 minutes, then take it out and dry it at 45°C to remove absolute ethanol. After drying, the PTFE microf...

Embodiment 3

[0051] A method for hydrophilic modification of PTFE flat microfiltration membrane, prepared from the following components in parts by weight: 1 part of polyethylene glycol monolaurate, 99 parts of ethanol solution, 0.5 part of polyvinyl alcohol, citric acid cross 0.1 part of joint agent, 99.4 parts of deionized water solvent, wherein the weight fraction of polyethylene glycol monolaurate is 1%, the weight fraction of polyvinyl alcohol is 0.5%, and the ratio of polyvinyl alcohol and citric acid is 5:1.

[0052] The modification method of the above-mentioned hydrophilized modified PTFE microfiltration membrane comprises the following preparation steps:

[0053] Step 1: Dissolve the surfactant in absolute ethanol and disperse it evenly at 1000r / min;

[0054] Step 2: Completely immerse the cleaned PTFE microfiltration membrane in the surfactant solution obtained in step 1 for 30 minutes, then take it out and dry it at 45°C;

[0055] Step 3: Dissolve polyvinyl alcohol in deionize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molar concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com