Porous glass and preparation method thereof

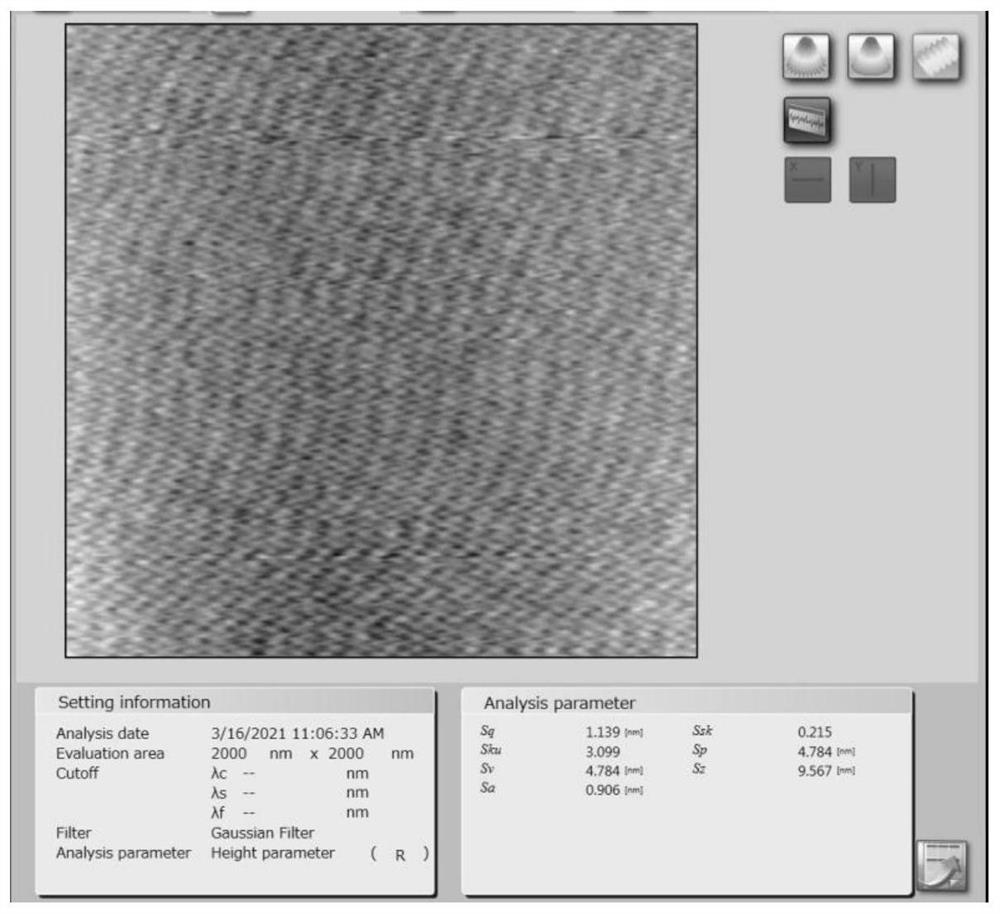

A porous glass and glass technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of polluting surface roughness, restricting the manufacture and application of regular porous glass, and low opening area to achieve good micropores Mass transfer performance, good chemical compatibility, small surface roughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

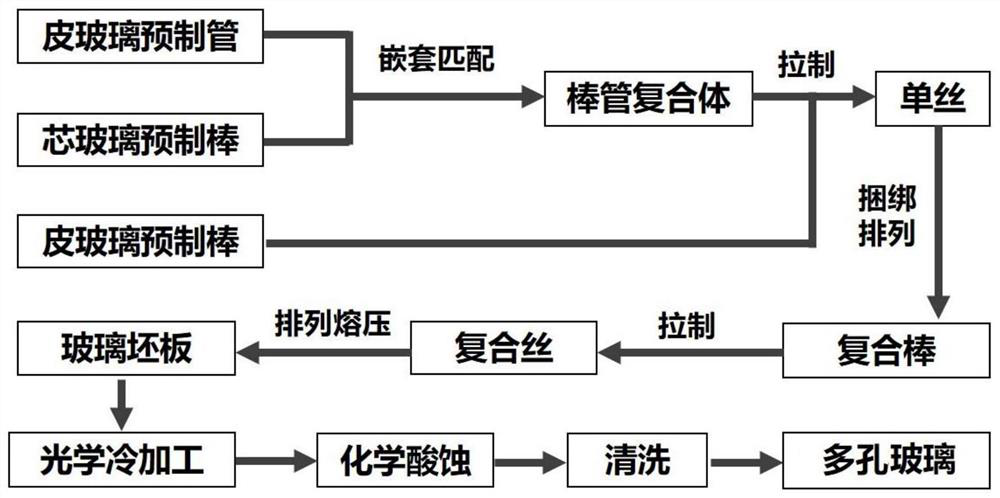

[0081] like figure 1 Shown, the preparation method of aforementioned porous glass that one embodiment of the present invention proposes, it comprises the following steps:

[0082] The components of the acid-soluble core material glass are mixed, melted, clarified under negative pressure and poured into molding to obtain the acid-soluble core material glass preform;

[0083] The porous glass matrix material is made into a skin glass prefabricated tube; the skin glass prefabricated tube is nested on the acid-soluble core material glass prefabricated rod, drawn by monofilaments and multifilaments, the multifilaments are arranged regularly, melted Press to obtain a rough plate segment, and then slice, spheronize, grind and polish to obtain a rough plate; carry out chemical acid etching on the rough plate to obtain porous glass;

[0084] The components of the acid-soluble core material glass are composed of 60-80 wt% of component A and 20-40 wt% of component B in terms of mass per...

Embodiment 1

[0188] A kind of porous glass, with borosilicate glass as a component, by weight percentage, it includes: SiO 2 72.5wt%; B 2 o 3 9.5wt%; Na 2 O 13.0wt% and CaO 5.0wt%; the coefficient of expansion of this borosilicate glass is 89×10 -7 / °C.

[0189] The porous glass is prepared by using the acid-soluble core glass component corresponding to Example 1 in Table 1 as the acid-soluble core glass, and is prepared by using glass rod tube drawing combined with acid etching to remove the core. The preparation process and the test results of the obtained porous glass are shown in Table 1.

[0190] The porous glass of Example 1 can be used as regular porous glass such as glass capillary arrays, porous glass collimators, and vitreous microwell plates.

Embodiment 2

[0192] A kind of porous glass, with lead silicate glass as a component, by weight percentage, it includes: SiO 2 51.5wt%; PbO 26.0wt%; Bi 2 o 3 7.0wt%; K 2 O+Na 2 O 9.0wt%; CaO+BaO 6.5wt%; the expansion coefficient of the lead silicate glass is 100×10 -7 / °C.

[0193] The porous glass uses the acid-soluble core glass component corresponding to Example 2 in Table 1 as the acid-soluble core glass, and is prepared by using glass rod tube drawing combined with acid etching to remove the core. The preparation process and test results of the obtained porous glass are shown in Table 1.

[0194] The porous glass of Example 2 can be used as regular porous glass such as vitreous microchannel plates, gene sequencing substrates, and vitreous microwell plates.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com