Oil-repellent and water-absorbent palygorskite-double-network gel sponge as well as preparation method and application thereof

A palygorskite and double-network technology, applied in the field of palygorskite-double-network gel sponge, can solve the problems of high separation cost, poor separation effect, and high separation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0030] As a specific embodiment of the present invention, a method for preparing an oil-repellent and water-absorbing palygorskite-double network gel sponge specifically comprises the following steps:

[0031] Step 1: Use palygorskite rough stone as raw material, grind and sieve the rough stone, take a certain amount of palygorskite powder, disperse it in water, and purify it with sulfuric acid, then centrifuge the dispersion, and dry the centrifuged precipitate Obtain the palygorskite powder of purification afterward;

[0032] Preferably, the centrifugal speed is 3500rpm-5000rpm.

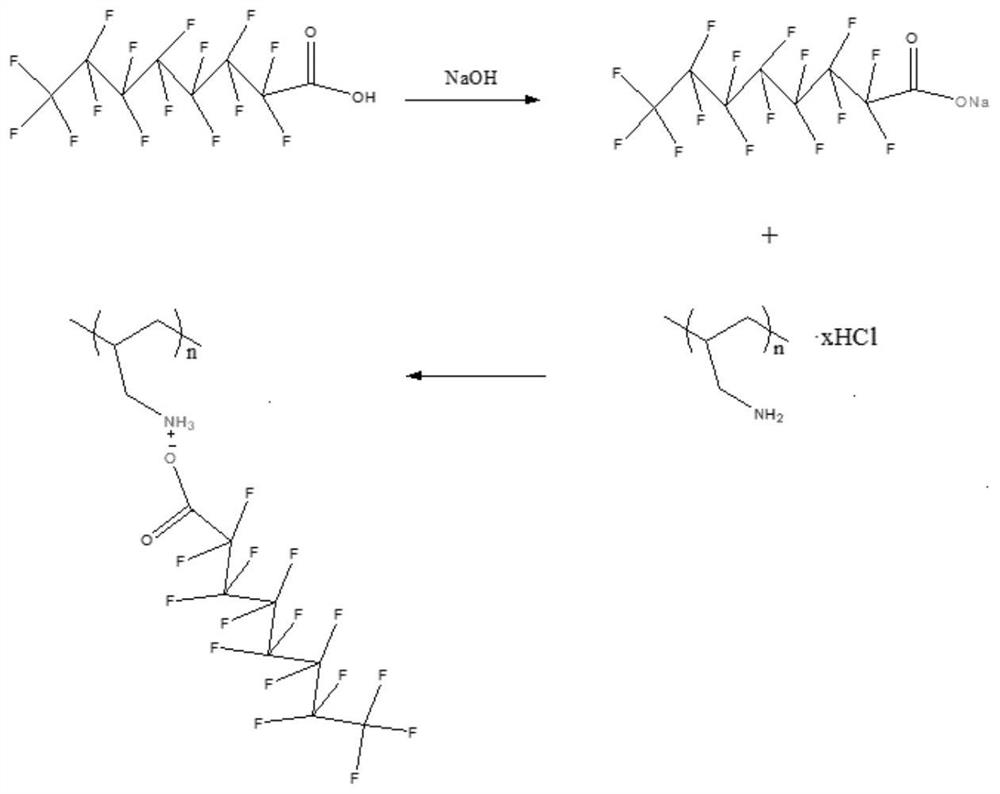

[0033] Step 2: dissolving a certain amount of polyallylamine hydrochloride in water to prepare a polyallylamine hydrochloride solution for subsequent use;

[0034] Preferably, the mass concentration of the polyallylamine hydrochloride solution is 2.5 mg / mL-5 mg / mL.

[0035] Step 3: Disperse the purified palygorskite powder obtained in step 1 in water, stir and sonicate until uniformly dispersed t...

Embodiment 1

[0047] A preparation method of palygorskite-double network gel sponge for oil repellency and water absorption, comprising the following steps:

[0048] Step 1: Use palygorskite raw stone as raw material, grind and sieve the raw stone, take a certain amount of palygorskite powder, disperse it in water, and purify it with sulfuric acid, then centrifuge the dispersion, and dry the centrifuged precipitate Obtain the palygorskite powder of purification afterward, and centrifugal rate is 3500rpm;

[0049] Step 2: Dissolving a certain amount of polyallylamine hydrochloride in water to prepare a polyallylamine hydrochloride solution for later use. The mass concentration of the polyallylamine hydrochloride solution is 2.5 mg / mL;

[0050] Step 3: Disperse the purified palygorskite powder obtained in step 1 in water, stir and sonicate until uniformly dispersed to obtain a palygorskite dispersion with a mass fraction of 3 wt%; the polyallylamine hydrochloride obtained in step 2 The salt ...

Embodiment 2

[0061] A preparation method of palygorskite-double network gel sponge for oil repellency and water absorption, comprising the following steps:

[0062] Step 1: Use palygorskite raw stone as raw material, grind and sieve the raw stone, take a certain amount of palygorskite powder, disperse it in water, and purify it with sulfuric acid, then centrifuge the dispersion, and dry the centrifuged precipitate Obtain the palygorskite powder of purification afterward, and centrifugal rate is 4000rpm;

[0063] Step 2: Dissolving a certain amount of polyallylamine hydrochloride in water to prepare a polyallylamine hydrochloride solution for later use. The mass concentration of the polyallylamine hydrochloride solution is 3 mg / mL;

[0064] Step 3: Disperse the purified palygorskite powder obtained in step 1 in water, stir and sonicate until uniformly dispersed to obtain a palygorskite dispersion with a mass fraction of 3 wt%; the polyallylamine hydrochloride obtained in step 2 The salt so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com