Soil petroleum hydrocarbon contamination remediation device and remediation method

A remediation method, petroleum hydrocarbon technology, applied in the field of soil remediation, can solve the problems of expensive construction, expression and cultivation of engineering strains, easy to destroy soil nutrients, etc., and achieve the effect of low cost, high safety and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

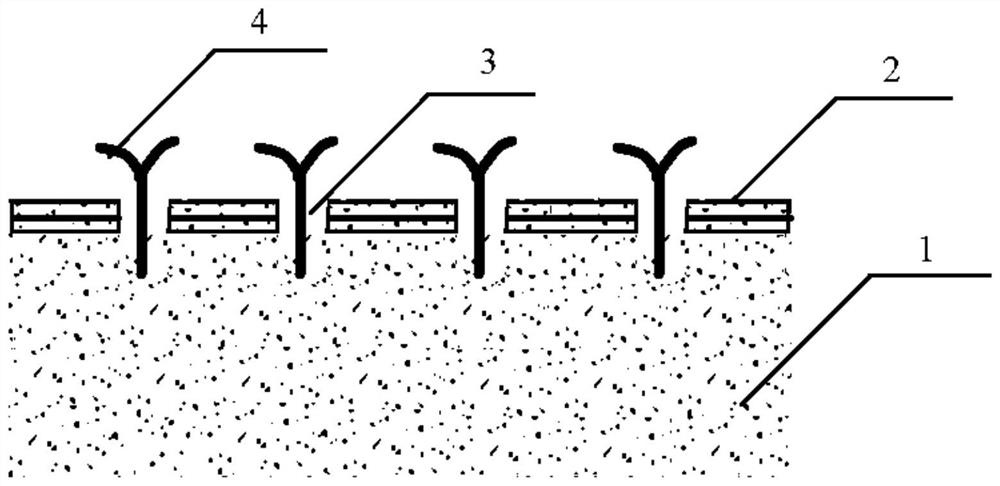

Image

Examples

Embodiment 1

[0062] Petroleum hydrocarbon-contaminated soil was obtained from the third oil production plant of Tianjin Dagang Oilfield. The collected contaminated soil samples were air-dried and pulverized. Sampling test showed that the total petroleum hydrocarbon content was 5092 mg / kg, and the remaining part was sterilized and dried to obtain a soil sample to be repaired.

[0063] Iris was planted in red soil for 3 months, the whole plant was pulled out, washed with deionized water, soaked in 0.01M dilute hydrochloric acid for 1 hour, dried and chopped, dried at 60°C, placed in a muffle furnace, and Nitrogen was introduced, and then the temperature was programmed to rise to 720°C at a rate of 6°C / min, and held for 60 minutes to obtain a modified biochar material with nanometer zero-valent iron average loading as iron-rich biochar.

[0064] Take part of the soil samples to be repaired and move them into flowerpots, mix iron-rich biochar with 20g / kg of soil, then spray 0.1g / L potassium p...

Embodiment 2

[0066] Iris was planted in red soil for 3 months, the whole plant was pulled out, washed with deionized water, soaked in 0.01M dilute hydrochloric acid for 1 hour, dried and chopped, dried at 70°C, placed in a muffle furnace, and Nitrogen was introduced, and then the temperature was programmed to 800°C at a rate of 8°C / min, and held for 55 minutes to obtain a modified biochar material with nanometer zero-valent iron average loading as iron-rich biochar.

[0067] Take part of the soil samples to be repaired in Example 1 and move them into flowerpots, mix iron-rich biochar with 20g / kg of soil, place them in a constant temperature box at 25 degrees Celsius, and water them every other day to keep the soil moist.

[0068] After 10 days, add microbial compound bacterial agent wherein, it is by 1.0 * 10 8 cfu / mL Bacillus pumilus (Shandong Nuojie Biotechnology Co., Ltd.), 1.0×10 8 cfu / mL Klebsiella michigans (Beijing Kezhan Biotechnology Co., Ltd.) and 1.0 × 10 7 cfu / mL Pseudomonas ...

Embodiment 3

[0071] Take part of the soil samples to be repaired in Example 1 and move them into a 20cm × 60cm rectangular planting tank, mix the iron-rich biochar obtained in Example 1 with the amount of 20g / kg soil, and spray 0.1g with the amount of 3g / kg soil / L potassium persulfate solution, placed in a sunny greenhouse at 25-30 degrees Celsius, watered every other day to keep the soil moist.

[0072] After 7 days, add microbial compound bacterial agent wherein, it is by 1.0 * 10 8 cfu / mL Bacillus pumilus (Shandong Nuojie Biotechnology Co., Ltd.), 1.0×10 8 cfu / mL Klebsiella michigans (Beijing Kezhan Biotechnology Co., Ltd.) and 1.0 × 10 7 cfu / mL Pseudomonas stutzeri (Beijing Kezhan Biotechnology Co., Ltd.) was mixed at a volume ratio of 2:2:1, and the amount added was 50ml / kg soil.

[0073] Then weave a straw layer about 5 cm thick with dry straw on the pot soil, leave 8 holes about 6 cm x 6 cm evenly, transplant iris under each hole, and water the next day.

[0074] After 60 days, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com