Rare earth oxide coated and modified ternary positive electrode material for lithium ion battery and preparation method of rare earth oxide coated and modified ternary positive electrode material

A rare earth oxide and lithium-ion battery technology, applied in battery electrodes, electrical components, secondary batteries, etc., can solve the problem of continuous stirring and evaporating water that consumes a lot of energy, lithium dissolution on the surface of ternary materials, and uniform coating Difficult to control the consistency of coating volume and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a preparation method of a ternary positive electrode material for a lithium-ion battery coated with a rare earth oxide, comprising the following steps:

[0037] Step 1: Uniformly disperse rare earth oxide nanoparticles in a solvent to obtain a mixed solution. The solvent is preferably absolute ethanol, industrial alcohol, ethylene glycol or deionized water. The uniform dispersion is not particularly limited. According to Conventional methods in this field are sufficient, preferably ultrasonic dispersion, mechanical stirring or physical shaking; the time for uniform dispersion is preferably 5-20 minutes;

[0038] Step 2: Add ternary positive electrode material precursor powder to the above mixed solution, stir and mix evenly to obtain a viscous slurry of ternary positive electrode material precursor evenly coated with rare earth oxide nanoparticles. The ternary material precursor is Ni x co y mn z (OH) 2 or Ni x co y al z (OH) ...

Embodiment 1

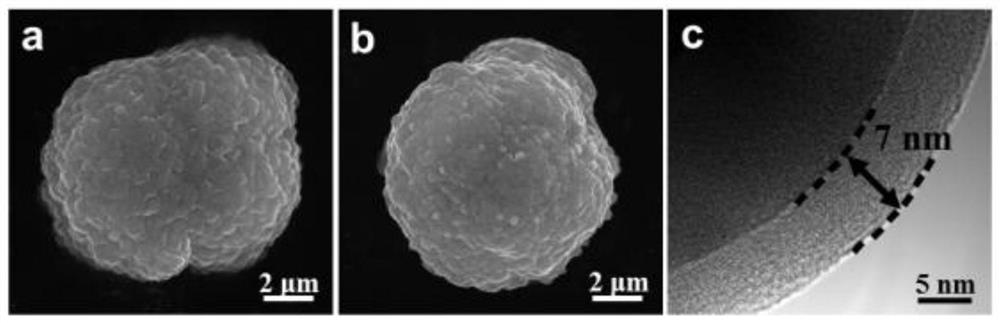

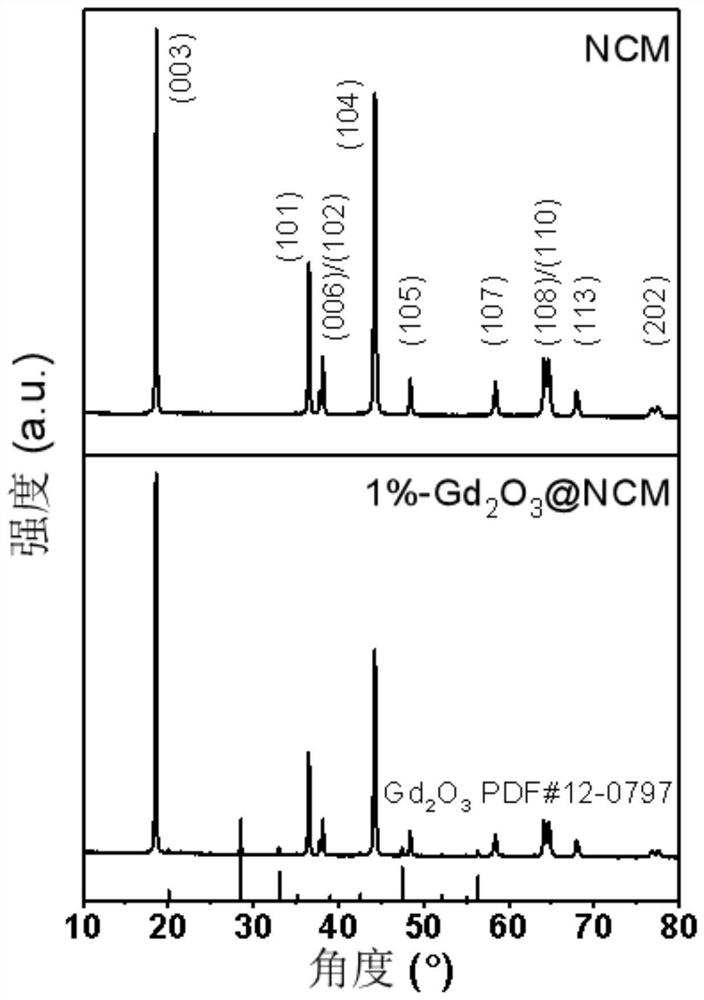

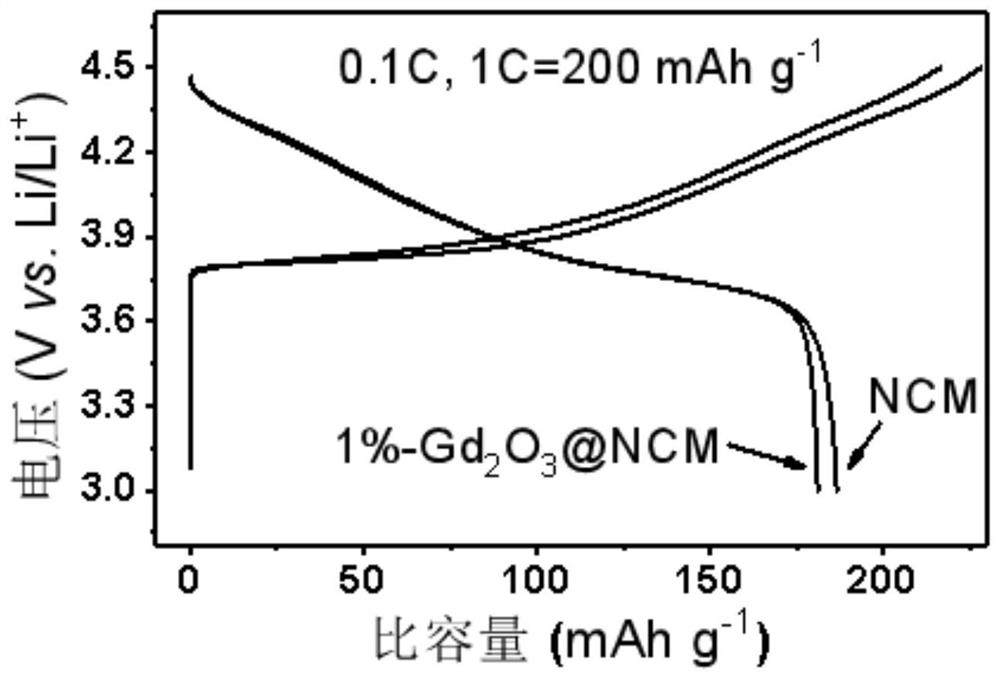

[0044] 1) 100 mg of commercially available Gd with a particle size of 100 nm 2 o 3 The particles were placed in 2ml of absolute ethanol and dispersed by ultrasonic for 10min to obtain evenly dispersed Gd 2 o 3 ethanol dispersion.

[0045] 2) Add 5g of Ni 0.6 co 0.05 mn 0.35 (OH) 2 The precursor of the ternary positive electrode material is placed in the above mixed solution, and is homogenized for 5 min at a speed of 2000 rpm / min by a homogenizer to obtain nanometer Gd 2 o 3 Uniformly coated precursor viscous slurry. This addition is equivalent to Gd 2 o 3 The molar ratio to the ternary material precursor is 0.01:1.

[0046] 3) The above viscous slurry was fully dried in an oven at 60°C and sieved, and then the mixed material was mixed with LiOH·H 2 The O powder was weighed and ground and mixed uniformly according to the molar ratio of 1:1.07. Finally, the uniformly mixed raw materials were first kept at 500°C for 3 hours in an air atmosphere, then at 800°C for 5 ...

Embodiment 2

[0049] Concrete steps and reaction conditions are identical with embodiment 1, and difference is, add and Ni respectively in step 1 0.6 co 0.05 mn 0.35 (OH) 2 The ternary material precursors are various rare earth oxides with a molar ratio of 0.01:1, including Y 2 o 3 , La 2 o 3 , CeO 2 、Pr 6 o 11 、Nd 2 o 3 、Sm 2 o 3 、Eu 2 o 3 , Tb 2 o 3 、Dy 2 o 3 、Ho 2 o 3 、Er 2 o 3 、Tm 2 o 3 , Yb 2 o 3 and Lu 2 o 3 , to obtain various rare earth oxide-coated ternary cathode materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com