Method for preparing magnesium building material product from magnesium-based desulfurization turbid liquid

A technology for turbid liquid and building materials, which is applied in the field of magnesium building materials products and magnesium-based desulfurization turbid solutions to prepare magnesium building materials products, can solve the problem that magnesium oxysulfide cement cannot provide sufficient magnesium sulfate concentration, and the early strength and water resistance of magnesium oxysulfide cement are reduced. Environmental pollution and other problems, to achieve the effect of high fire rating, good fluidity and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The raw materials for preparing the formula are: 100g of light-burned magnesium oxide powder, 80g of magnesium sulfate heptahydrate, 50g of desulfurization turbid liquid, 30g of steel slag powder, 15g of sawdust, 5g of straw, and 2g of citric acid.

[0025] Example 1 The preparation process of a magnesium-based desulfurization turbid liquid for preparing magnesium building materials includes the following steps:

[0026] 1) Dry mixing of raw materials: Weigh lightly burned magnesia powder, steel slag powder, wood chips, and straw, put them into a mixer at 80-100 rpm for dry mixing, and control the dry mixing time to 2 minutes;

[0027] 2) Solution preparation: mix magnesium sulfate with water and turbid solution for 2 minutes to obtain a magnesium sulfate solution; then add additives citric acid and phosphoric acid to the magnesium sulfate solution, and fully stir for 2 minutes to obtain a solution;

[0028] 3) Solid-liquid mixing: Add the dry mixture prepared in step 1...

Embodiment 2

[0034] The raw materials for preparing the formula are: 100g of light-burned magnesium oxide powder, 65g of desulfurization turbid liquid, 65g of magnesium sulfate heptahydrate, 30g of steel slag powder, 15g of sawdust, 5g of straw, and 2g of citric acid.

[0035] Embodiment 2 A kind of magnesium-based desulfurization turbid liquid prepares the preparation process of magnesium building material product with embodiment 1.

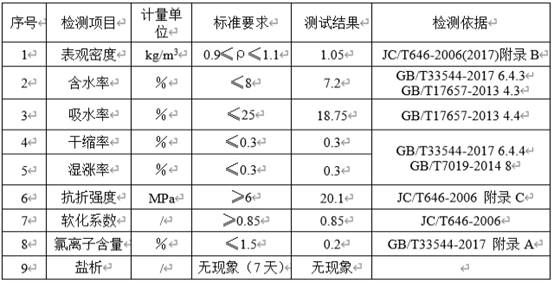

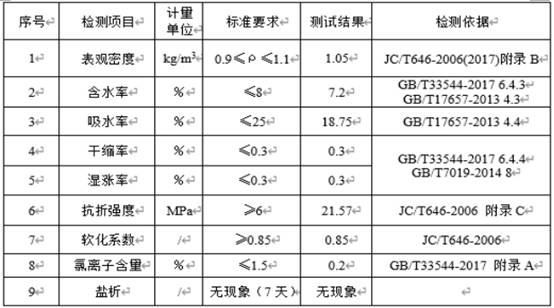

[0036] The product inspection results are shown in Table 2:

[0037] Table 2

[0038]

Embodiment 3

[0040] The raw materials for preparing the formula are: 100g of light-burned magnesium oxide, 55g of magnesium sulfate heptahydrate, 75g of desulfurization turbid liquid, 30g of steel slag powder, 15g of sawdust, 5g of straw, and 2g of citric acid.

[0041] Example 3 The preparation process of a magnesium-based desulfurization turbid liquid to prepare magnesium building materials is the same as that of Example 1.

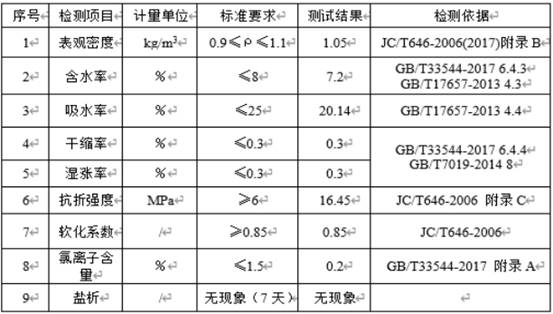

[0042] The product inspection results are shown in Table 3:

[0043] table 3

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com