Modified polyhalogenated styrene-1,3-butadiene emulsion binder as well as preparation and application thereof

A technology of halogenated styrene and butadiene, which is applied in adhesives, secondary batteries, structural parts, etc., can solve problems such as pass rate and electrochemical performance, and achieve improved adhesion, increased content, and reduced interface Effects of Impedance and Electrochemical Internal Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A preparation method of modified polyhalogenated styrene-1,3-butadiene emulsion binder, comprising the following steps:

[0064] S1. Preparation of aqueous phase pre-emulsion: 45kg of deionized water, 8kg of carbon nanotubes, 3kg of vinyltriethoxysilane, 1.5kg of ammonium dodecylbenzenesulfonate, 1kg of sodium lauryl sulfate, alkylphenol 0.5 kg of polyoxyethylene ether, 0.3 kg of isooctyl 3-mercaptopropionate, 2.8 kg of diacetone acrylamide, and 0.1 kg of potassium methyl siliconate were stirred evenly to obtain an aqueous phase pre-emulsion.

[0065] S2. Segmented polymerization reaction:

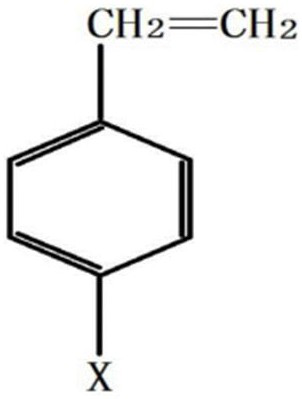

[0066] In the first stage of polymerization reaction, the polymerization tank is evacuated, the vacuum degree is -0.1MPa, and 6.22kg of water phase pre-emulsion, 4.5kg of 4-F-styrene, 4kg1,3-butadiene, 0.02kg of neodecyl peroxide are put in Cumyl peroxide, 4kg of water, wherein cumyl peroxyneodecanoate was pre-mixed with water, heated to 75°C, reacted for 0.5 hours,

[0067] In th...

Embodiment 2

[0079] A preparation method of modified polyhalogenated styrene-1,3-butadiene emulsion binder, comprising the following steps:

[0080] S1. Preparation of aqueous phase pre-emulsion: 45kg of deionized water, 8kg of nano-graphene, 3kg of vinyltriethoxysilane, 1.5kg of ammonium dodecylbenzenesulfonate, 1kg of sodium lauryl sulfate, alkylphenol 0.5 kg of polyoxyethylene ether, 0.3 kg of isooctyl 3-mercaptopropionate, 2.8 kg of diacetone acrylamide, and 0.1 kg of potassium methyl siliconate were stirred evenly to obtain an aqueous phase pre-emulsion.

[0081] S2. Segmented polymerization reaction:

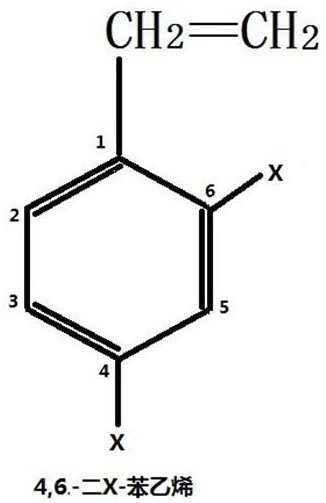

[0082] In the first stage of polymerization reaction, the polymerization tank is evacuated, the vacuum degree is -0.1MPa, and 6.22kg of water phase pre-emulsion, 4.5kg of 2,4-diF-styrene, 4kg of 1,3-butadiene, 0.02kg of over Oxygenated cumyl neodecanoate, 4kg of water, wherein the cumyl peroxyneodecanoate was mixed with water uniformly in advance, heated to 75°C, and reacted for 0.5 h...

Embodiment 3

[0095] A preparation method of modified polyhalogenated styrene-1,3-butadiene emulsion binder, comprising the following steps:

[0096] S1. Preparation of aqueous phase pre-emulsion: 45kg of deionized water, 8kg of nano-amorphous carbon, 3kg of vinyltriethoxysilane, 1.5kg of ammonium dodecylbenzenesulfonate, 1kg of sodium lauryl sulfate, alkyl 0.5 kg of phenol polyoxyethylene ether, 0.3 kg of isooctyl 3-mercaptopropionate, 2.8 kg of diacetone acrylamide, and 0.1 kg of potassium methyl siliconate were stirred evenly to obtain an aqueous phase pre-emulsion.

[0097] S2. Segmented polymerization reaction:

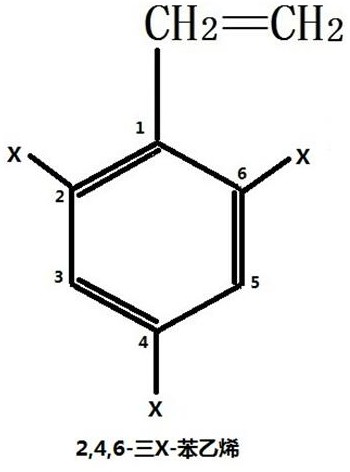

[0098] In the first stage of polymerization reaction, the polymerization tank is evacuated, the vacuum degree is -0.1MPa, and 6.22kg of water phase pre-emulsion, 4.5kg of 2,4,6-triF-styrene, 4kg of 1,3-butadiene, 0.02 kg cumyl peroxyneodecanoate, 4kg of water, wherein cumyl peroxyneodecanoate was pre-mixed with water, heated to 75 ° C, reacted for 0.5 hours,

[0099] In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com