Aspergillus niger recombinant strain capable of massively expressing Candida antarctica lipase B as well as construction method and application of aspergillus niger recombinant strain

A construction method and lipase technology are applied in the construction and application fields of high-yielding lipase B recombinant expression strains of Aspergillus niger, which can solve the problems of low expression and achieve the effect of high-efficiency secretory expression.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

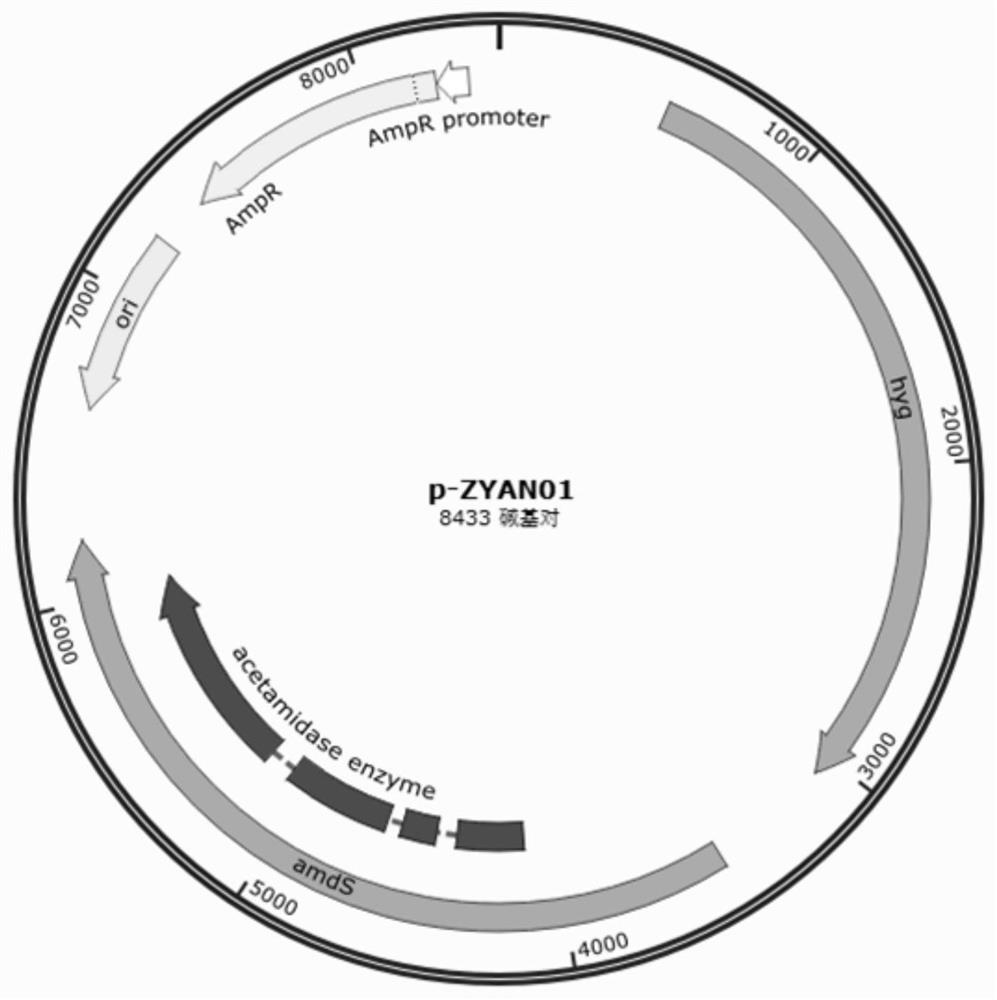

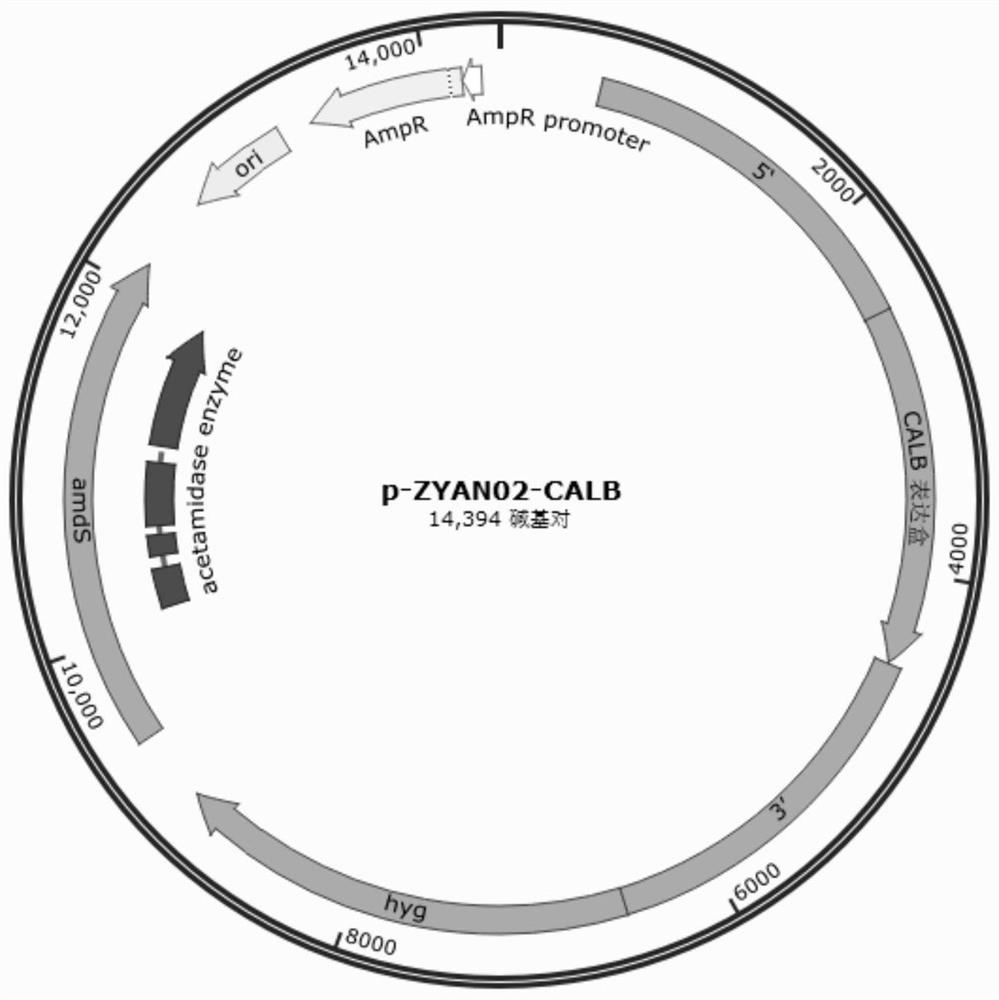

[0031] Embodiment 1: Construction of p-ZYAN02-CALB plasmid

[0032] The preparation of the plasmid mainly includes the following two steps: 1. Preparation of the intermediate plasmid p-ZYAN01. 2. Linearization of the intermediate plasmid p-ZYAN01, and integration of the lipase B gene expression cassette and upstream and downstream homologous fragments into p-ZYAN01 to form p-ZYAN02-CALB plasmid

[0033] The method for preparing the intermediate plasmid p-ZYAN01 is as follows:

[0034] p-ZYAN01 is mainly composed of the following parts and the necessary connecting sequence, or directly combined with the following parts.

[0035] (1) 2305bp fragment obtained after XbaI-PscI double digestion of pUC57 plasmid;

[0036] (2) hyg gene expression cassette, the sequence is shown in SEQ ID NO.3;

[0037] (3) amds expression cassette, the sequence is shown in SEQ ID NO.4.

[0038] The 2305bp fragment obtained after pUC57 plasmid XbaI-PciI double digestion, the hyg gene expression cas...

Embodiment 2

[0039] Example 2: Transformation integration of lipase B expression cassette

[0040]The starting strain of this example is ZYAN05, which is obtained by knocking out the glucoamylase gene, fungal amylase gene and acid amylase gene from a conventional strain. The above-mentioned gene knockout / knock-in method in Aspergillus niger can be realized by referring to the technical methods disclosed in the examples of patent CN103937766A or CN104962594A. That is, refer to the method described by Delmas (Appl Environ Microbiol. 2014, 80(11): 3484-7) et al. Specifically, a circular DNA vector is used, which contains the above-mentioned 5' and 3' homologous sequences, a selectable marker, and an E. coli replication sequence. The circular vector was transformed into Aspergillus niger, and the recombinant strain was obtained by selection.

[0041] The p-ZYAN02-CALB plasmid is imported into Aspergillus niger strain ZYAN05 by the protoplast transformation method, and the specific operation ...

Embodiment 4

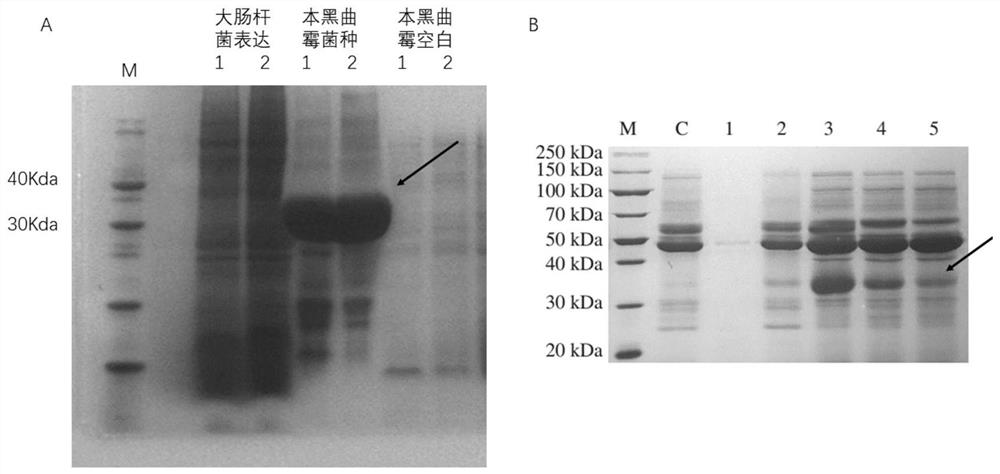

[0043] Embodiment 4 recombinant expression strain liquid fermentation produces lipase B

[0044] Slant culture: Take an inoculation loop of the bacterial lawn of the recombinant expression strain of Aspergillus niger and inoculate it on a PDA solid slope, and cultivate it at a constant temperature at 35°C for 60 hours; Shake flask culture: Take an inoculation loop of bacterial lawn from the strain obtained on the slope and insert it into the seeds for cultivation culture medium at an initial pH of 5.5, 35°C, and a shaker speed of 200 rpm for about 72 hours. The following table shows the fermentation enzyme production of 3 batches of 250ml shake flasks. The average enzyme production level is 10600unit / L of synthetic enzyme activity, and the crude protein content of the supernatant is 4g / L.

[0045] batch Fermentation period (h) Fermentation enzyme activity (unit / L) Crude protein (g / L) 1 72 9995 3.8g / L 2 78 12030 4.4g / L 3 75 9775 3.8g / L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com