FeCrAl-based alloy with double heterostructures and preparation method for FeCrAl-based alloy

A technology of heterostructure and base alloy, applied in the field of metal materials, to achieve the effect of preventing coarsening, good plasticity and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A method for preparing a FeCrAl-based alloy with a double heterostructure, comprising the following steps:

[0042] Step 1. Solid solution treatment of FeCrAl-based alloy at 950° C.-1100° C., and then cooling to room temperature.

[0043] The FeCrAl-based alloy, by mass percentage, includes 12-15% of chromium, 4-5% of aluminum, 1-4% of molybdenum, 0.5-3% of niobium, 0.1-2% of silicon, and inevitable impurity content ≤0.2%, the balance is iron.

[0044] The solid solution time is 5min-240min, and the cooling method is water cooling, oil cooling or air cooling.

[0045] Step 2, performing rolling deformation on the alloy obtained in step 1 with a reduction of 30%-80%.

[0046] The rolling process is as follows: the single-pass reduction during rolling deformation is 5% to 15%, and the rolling temperature is from room temperature to 600°C.

[0047] Step 3, heating the alloy obtained in step 2 to 500°C-800°C for aging treatment, and then cooling to room temperature.

[...

Embodiment 1

[0053] A preparation method of a FeCrAl-based alloy with a double heterogeneous structure is carried out in the following steps:

[0054] Step 1. First select the alloy composition as chromium: 13.5%, aluminum: 4%, molybdenum: 2%, niobium: 1%, silicon: 0.2%, and the balance (by mass percentage) is FeCrAl-based iron and industrial standard impurities. Alloy forgings, and the alloy was solid solution treated at 1050°C for 60min, and cooled to room temperature with water.

[0055] Step 2. Cold-rolling and deforming the alloy obtained in step 1 at room temperature, with a rolling reduction of 10% in a single pass and a total reduction of 80%.

[0056] Step 3. Heat the alloy obtained in step 2 to 600° C. for aging treatment for 60 minutes, and then air-cool to room temperature.

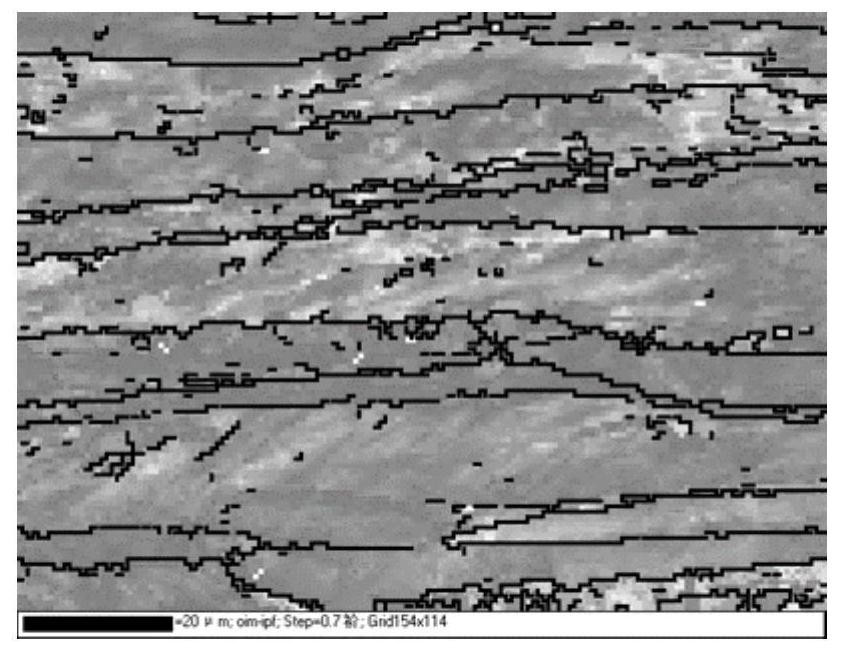

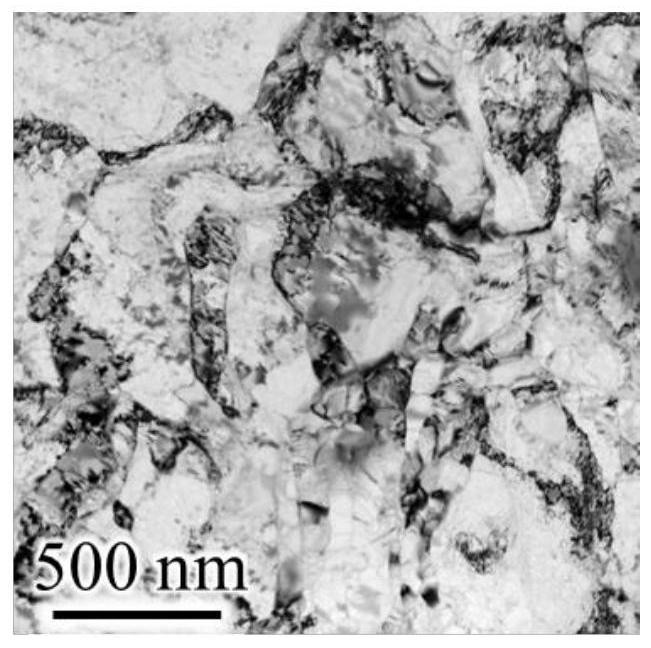

[0057] The layered ferrite grains in the alloy structure obtained in this example are as follows: figure 1 As shown, grain width ~ 16μm; equiaxed ferrite grains such as figure 2 As shown, the grain siz...

Embodiment 2

[0059] A preparation method of a FeCrAl-based alloy with a double heterogeneous structure is carried out in the following steps:

[0060] Step 1. First select the alloy composition as chromium: 12%, aluminum: 4%, molybdenum: 1%, niobium: 0.5%, silicon: 0.2%, and the balance (by mass percentage) is iron and FeCrAl-based impurities that meet industrial standards Alloy forgings, and the alloy was solid solution treated at 1100 ° C for 60 min, and water cooled to room temperature.

[0061] Step 2. Cold-rolling and deforming the alloy obtained in step 1 at room temperature, with a rolling reduction of 10% in a single pass and a total reduction of 80%.

[0062] Step 3. Heat the alloy obtained in step 2 to 800° C. for aging treatment for 60 minutes, and then air-cool to room temperature.

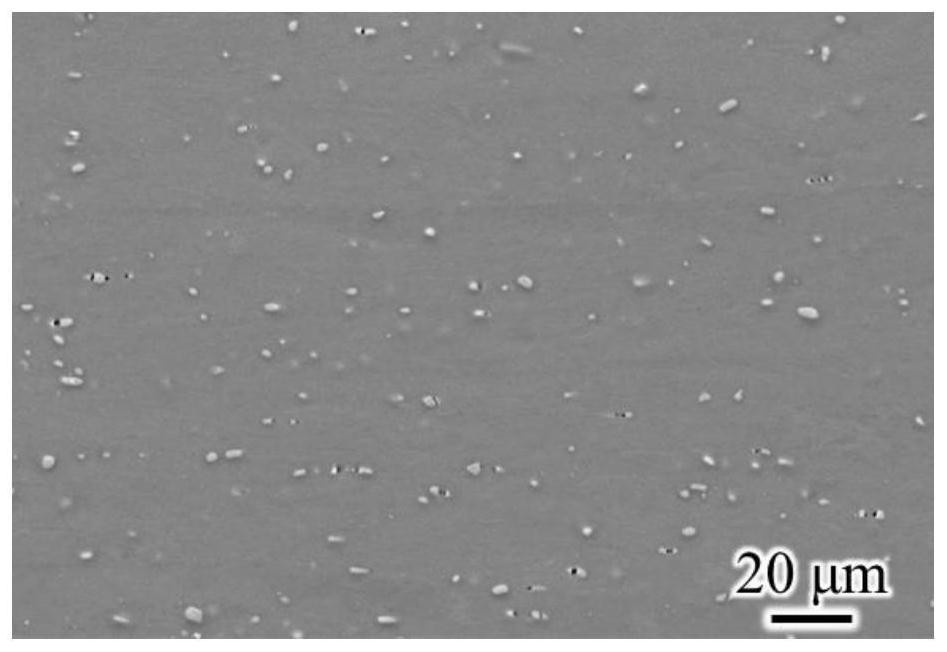

[0063] In this embodiment, when the solid solution temperature is increased to 1100°C, there is still a certain amount of micron-sized Laves second phase remaining, such as Figure 6 As shown, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com