Negative plate, preparation method of negative plate, and lithium ion battery

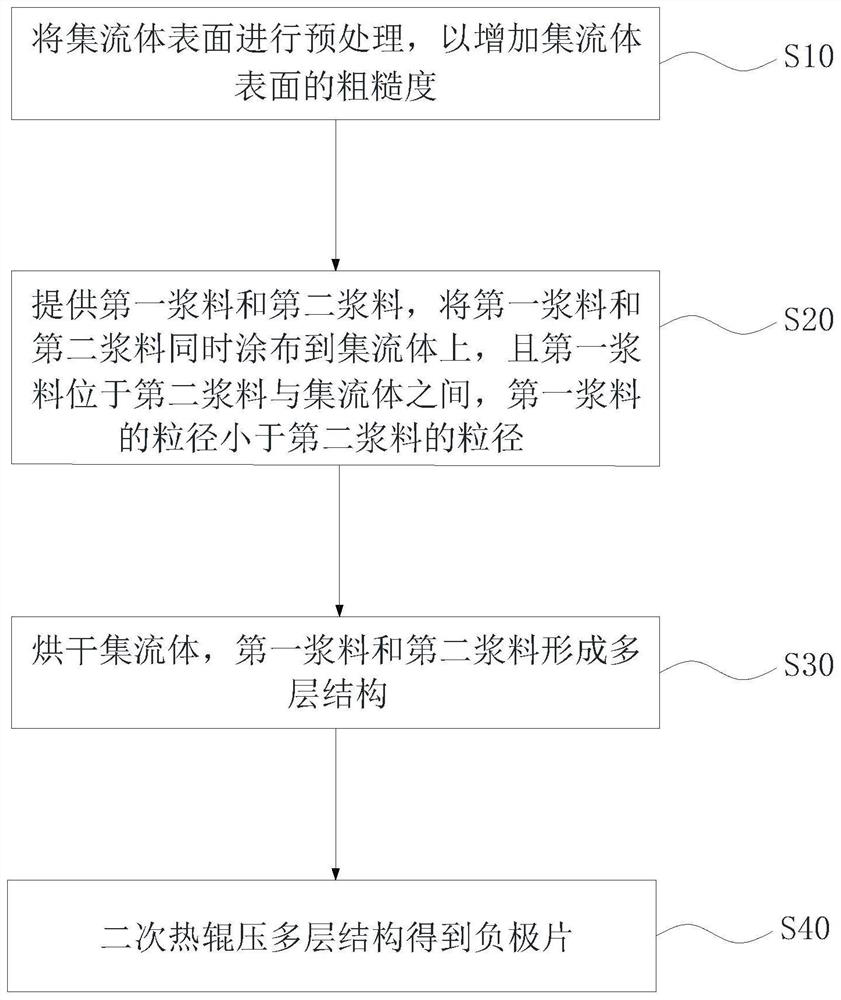

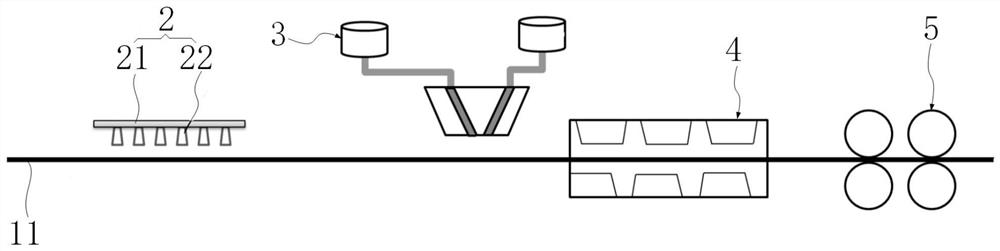

A technology of negative electrode sheet and conductive agent, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as increasing the contact distance between the underlying active material and the electrolyte, the battery capacity cannot function normally, and prolonging the migration path of lithium ions. , to improve the liquid absorption efficiency, reduce the phenomenon of lithium precipitation, and improve the peel strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

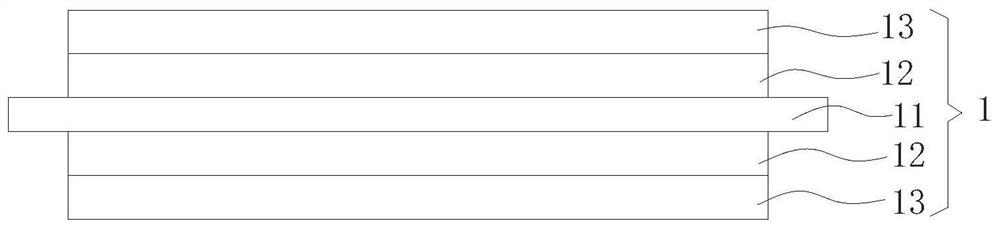

[0050] The current collector 11 of the negative electrode sheet 1 is made of copper foil, and the thickness of the copper foil is 10um;

[0051] The active main material, conductive agent, thickener, and binding agent of the first slurry are 90%:1%:4.5%:4.5% according to mass ratio, and the active main material, conductive agent, thickener of the second slurry , binder is 95%: 1%: 2%: 2% according to mass ratio, wherein, the active main material of the first slurry adopts the graphite of particle diameter 4um, the active main material of the second slurry adopts the graphite of particle diameter 15um. Graphite, the conductive agent of the first slurry and the second slurry adopts spherical conductive carbon black, and the binder content of the first slurry is 2.25 times of the binder content of the second slurry;

[0052] The thickness of the first coating 12 of the negative electrode sheet 1 is 90um, and the thickness of the first coating 12 is 50% of the coating thickness of...

Embodiment 2

[0059] The current collector 11 of the negative electrode sheet 1 is made of copper foil, and the thickness of the copper foil is 10um;

[0060] The active main material, conductive agent, thickener, and binding agent of the first slurry are 90%:1%:4.5%:4.5% according to mass ratio, and the active main material, conductive agent, thickener of the second slurry , binder is 95%: 1%: 2%: 2% according to mass ratio, wherein, the active main material of the first slurry adopts the graphite of particle diameter 4um, the active main material of the second slurry adopts the graphite of particle diameter 15um. Graphite, the conductive agent of the first slurry and the second slurry adopts spherical conductive carbon black, and the binder content of the first slurry is 2.25 times of the binder content of the second slurry;

[0061] The thickness of the first coating 12 of the negative electrode sheet 1 is 90um, and the thickness of the first coating 12 is 30% of the coating thickness of...

Embodiment 3

[0068] The current collector 11 of the negative electrode sheet 1 is made of copper foil, and the thickness of the copper foil is 10um;

[0069] The active main material, conductive agent, thickener, and binding agent of the first slurry are 92%:1%:4%:3% according to the mass ratio, and the active main material, conductive agent, thickener of the second slurry , binder according to mass ratio is 96.5%: 0.5%: 1.5%: 1.5%, wherein, the active main material of the first slurry adopts the graphite of particle diameter 4um, the active main material of the second slurry adopts the graphite of particle diameter 20um Graphite, the conductive agent of the first slurry and the second slurry adopts spherical conductive carbon black, and the binder content of the first slurry is 2 times of the binder content of the second slurry;

[0070] The thickness of the first coating 12 of the negative electrode sheet 1 is 90um, and the thickness of the first coating 12 is 50% of the coating thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com