Ultrathin carbon-coated amorphous/crystal heterogeneous phase NiFe alloy nanometer material and preparation method and application thereof

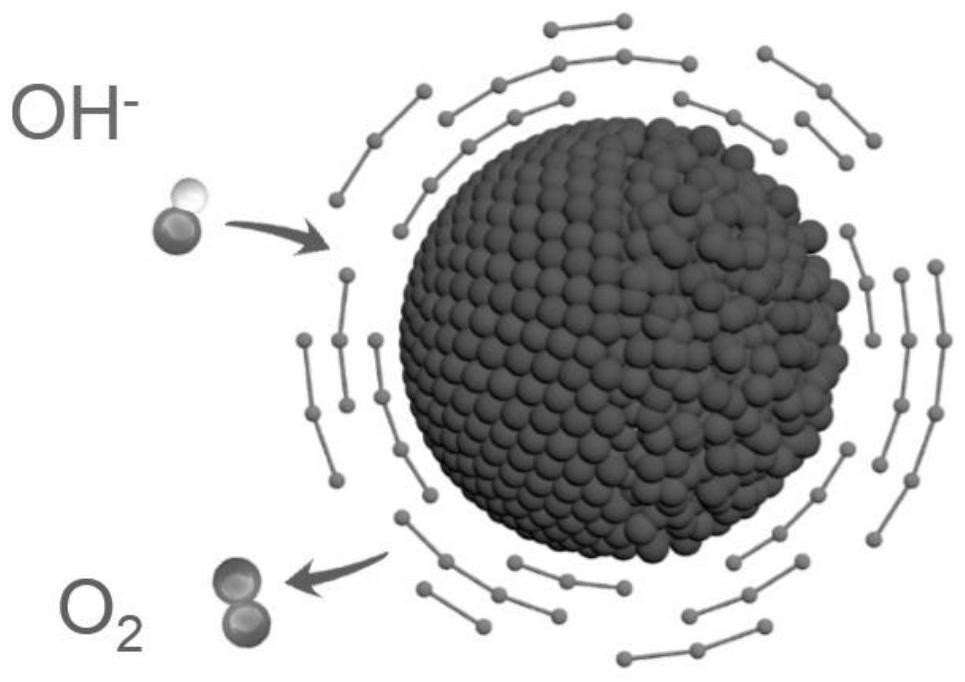

An alloy nanomaterial, amorphous technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem that has not been used to prepare metastable amorphous/crystalline heterophase structures, etc. problems, to achieve excellent OER performance, improve electrochemical stability, and increase the effect of exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

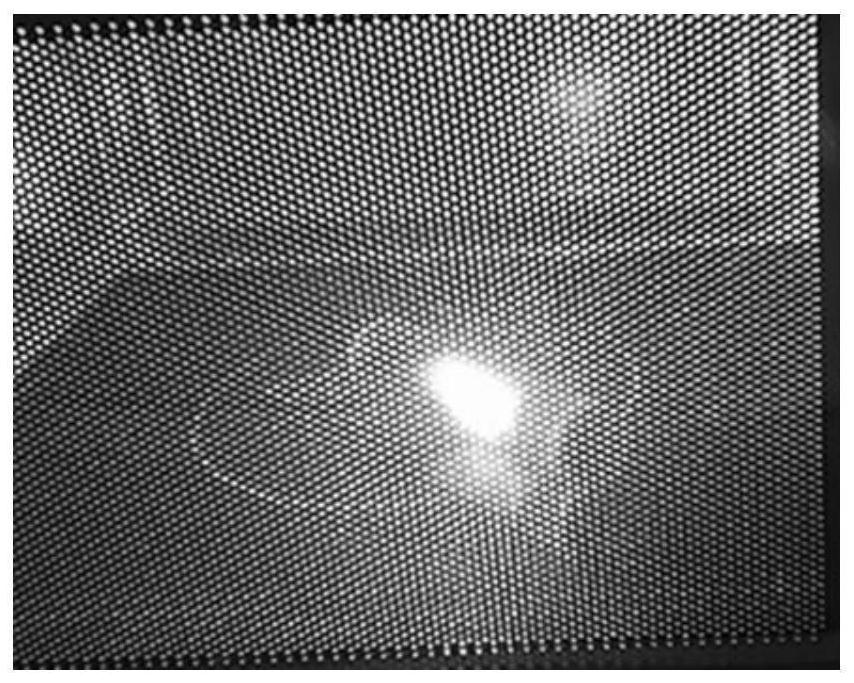

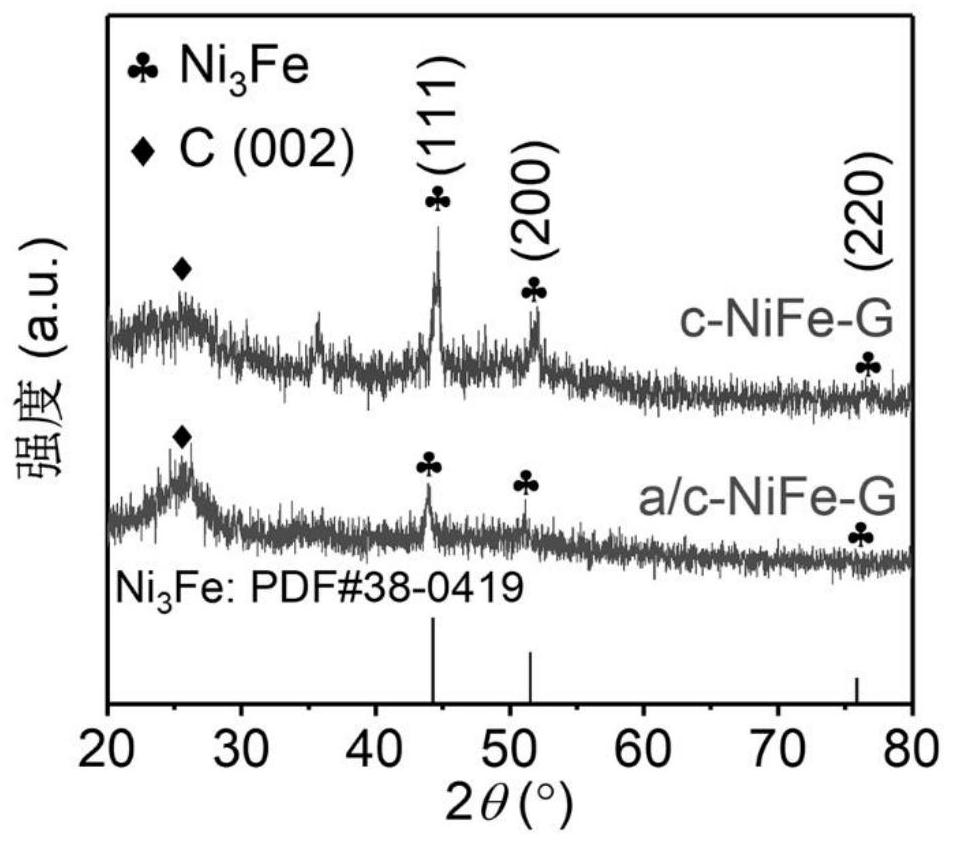

[0041] A kind of preparation method of ultra-thin carbon coated amorphous / crystal heterogeneous phase NiFe alloy nanomaterial, preparation schematic diagram is as follows Figure 11 As shown, it specifically includes the following steps:

[0042] 1) Graphene oxide (GO) is prepared by the improved Hummers method, which specifically includes the following steps: firstly take 360mL of concentrated sulfuric acid, add 40mL of concentrated phosphoric acid, and then add 3g of graphite flakes. After stirring evenly, slowly add 18g of potassium permanganate, place in a stirring water bath at 50°C and heat for 12h; then, after the temperature is cooled to room temperature, add about 400mL of ice water and 10mL of hydrogen peroxide, and after settling for 3 times, pickling, ethanol, and water Neutral or so; finally dialyzed in pure water for a week to obtain graphene oxide (GO);

[0043] 2) Use graphene oxide (GO) in step 1) to prepare a GO suspension with a concentration of 2 mg / mL; so...

Embodiment 2

[0048] A method for preparing ultra-thin carbon-coated amorphous / crystalline heterogeneous phase NiFe alloy nanomaterials. The difference from Example 1 is that in step 2), the total amount of Ni and Fe metals is 4.5wt% of the GO mass.

Embodiment 3

[0050] A method for preparing ultra-thin carbon-coated amorphous / crystalline heterogeneous phase NiFe alloy nanomaterials. The difference from Example 1 is that in step 2), the total amount of Ni and Fe metals is 15 wt% of the GO mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com