Method for preparing zinc silicate crystal glaze from granite

A zinc silicate and crystalline glaze technology, which is applied in the field of preparing zinc silicate crystalline glaze, can solve the problems of wasting manpower and material resources, and the crystal effect cannot be guaranteed, so as to reduce the molding cycle, improve transparency, rigidity and surface gloss , Improve the effect of growth and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

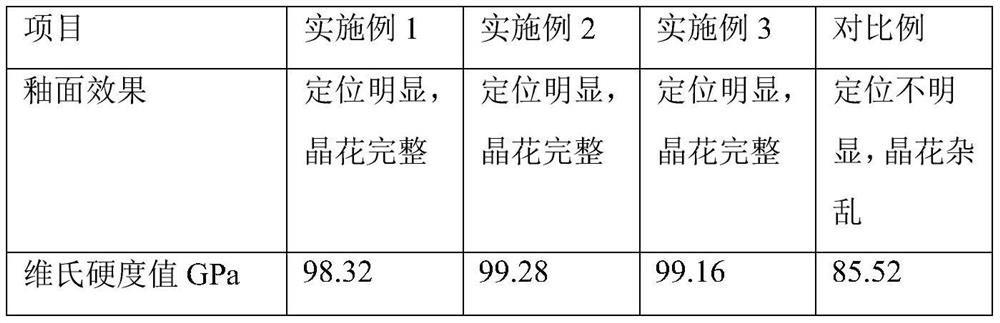

Embodiment 1

[0022] A method for preparing zinc silicate crystalline glaze from granite, comprising the following steps: 18 parts of granite, 11 parts of kaolin, 6 parts of quartz, 3 parts of limestone, 14 parts of glass powder, 2 parts of barium carbonate, 5 parts of corundum powder, sodium 6 parts of feldspar, 4 parts of talcum powder, 3 parts of methyl phosphate, and 3 parts of zinc oxide are weighed and mixed according to parts by weight, and water and aluminum balls are added for ball milling. In the ball milling process, the weight ratio of water: raw materials: balls is 3:2:1, the ball-milled glaze is passed through a 130-mesh sieve, the sieved glaze and green body are put into the mold and formed by dry pressing, the glaze and molding are completed together, and the glaze amount is 1.2kg / m 2 , put it in a drying room at 15°C for drying, and finally put it in a kiln for firing, raise the temperature to 1250°C at a rate of 5°C / min and keep it for 30 minutes, then slowly cool down to 1...

Embodiment 2

[0024] A method for preparing zinc silicate crystalline glaze from granite, comprising the following steps: 21 parts of granite, 14 parts of kaolin, 8 parts of quartz, 5 parts of limestone, 16 parts of glass powder, 4 parts of barium carbonate, 6 parts of corundum powder, sodium 8 parts of feldspar, 6 parts of talcum powder, 4 parts of ethyl phosphate, and 5 parts of zinc oxide are weighed and mixed according to parts by weight, and water and aluminum balls are added for ball milling. In the ball milling process, the weight ratio of water: raw materials: balls is 3:2:1, the ball-milled glaze is passed through a 140-mesh sieve, the sieved glaze and green body are put into the mold and formed by dry pressing, the glaze and molding are completed together, and the glaze amount is 1.5kg / m 2 , put it in a drying room at 17°C for drying, and finally put it in a kiln for firing, raise the temperature to 1250°C at a speed of 5°C / min and keep it for 30 minutes, then slowly cool down to 1...

Embodiment 3

[0026] A method for preparing zinc silicate crystalline glaze from granite, comprising the following steps: 24 parts of granite, 17 parts of kaolin, 10 parts of quartz, 6 parts of limestone, 18 parts of glass powder, 5 parts of barium carbonate, 8 parts of corundum powder, sodium 9 parts of feldspar, 8 parts of talcum powder, 5 parts of phenyl phosphate, and 7 parts of zinc oxide are weighed and mixed according to parts by weight, and water and aluminum balls are added for ball milling. In the ball milling process, the weight ratio of water: raw materials: balls is 3:2:1, the ball-milled glaze is passed through a 150-mesh sieve, the sieved glaze and green body are put into the mold and formed by dry pressing, the glaze and molding are completed together, and the glaze amount is 1.8kg / m 2 , put it in a drying room at 20°C for drying, and finally put it in a kiln for firing, raise the temperature at a rate of 5°C / min to 1250°C and keep it for 30 minutes, then slowly cool down to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com