Sargassum pallidum fucosan as well as preparation method and application thereof

A technology of fucoidan and artemisia fucus, which is applied in the field of natural polymers, can solve the problems of extraction and purification and anti-H1N1 influenza virus research that have not been reported, and achieve the effect of increased anti-H1N1 influenza virus activity and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention provides the preparation method of above-mentioned sea wormwood fucoidan, comprises the following steps:

[0035] (1) Degreasing: reflux the sea wormwood powder with 95% ethanol at 75-90°C for 3-5h, repeat 2-3 times, remove lipid and dry the residue;

[0036] (2) Hot water extraction: The degreased dry powder is extracted with hot water at 70-90°C for 2-3 hours according to the mass-volume ratio of material to liquid at 1:10-50, repeated 2-3 times, centrifuged, and all supernatants are collected. concentrate;

[0037] (3) CaCl 2 Alginate removal: 3mol / L CaCl 2 Settle at 4°C for 8-12 hours, repeat 1-2 times, centrifuge, dialyze, concentrate and freeze-dry the supernatant to obtain crude sea sage fucoidan;

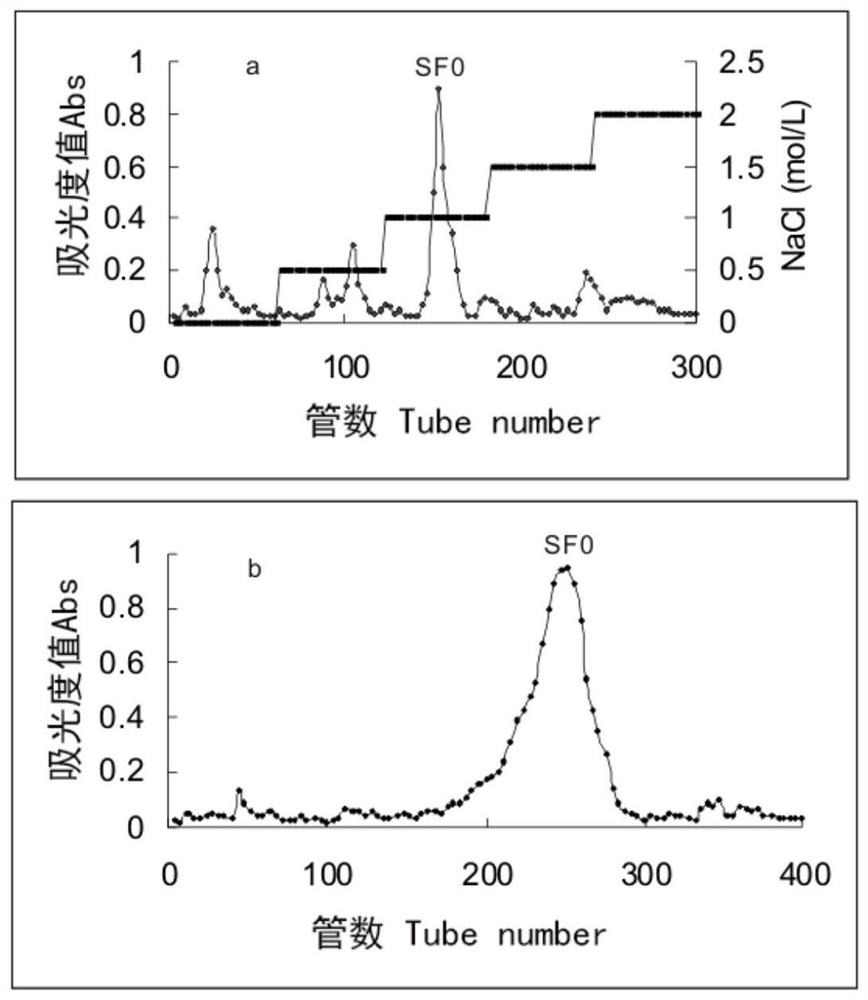

[0038] (4) Purification: The crude sea wormwood fucoidan was chromatographed on the Q-Sepharose Fast Flow column, and deionized water and NaCl solution (0.5, 1, 1.5, 2mol / L) were eluted with a gradient of 3 mL / min, and each Connect 6mL tubes...

Embodiment 1

[0046] Distill the sea wormwood powder with 95% ethanol at 85°C for 4h (3 times) to remove the lipid and dry the residue, pulverize; the obtained powder was extracted with 80°C hot water at a solid-liquid ratio of 1:30 for 3h (repeat 3 times), centrifuge, collect all supernatant, concentrate; add CaCl 2 to 3 mol / L, the sedimentation temperature was 4°C, and stood for 10 hours, then centrifuged, dialyzed, concentrated and freeze-dried the supernatant to obtain crude sea wormwood fucoidan.

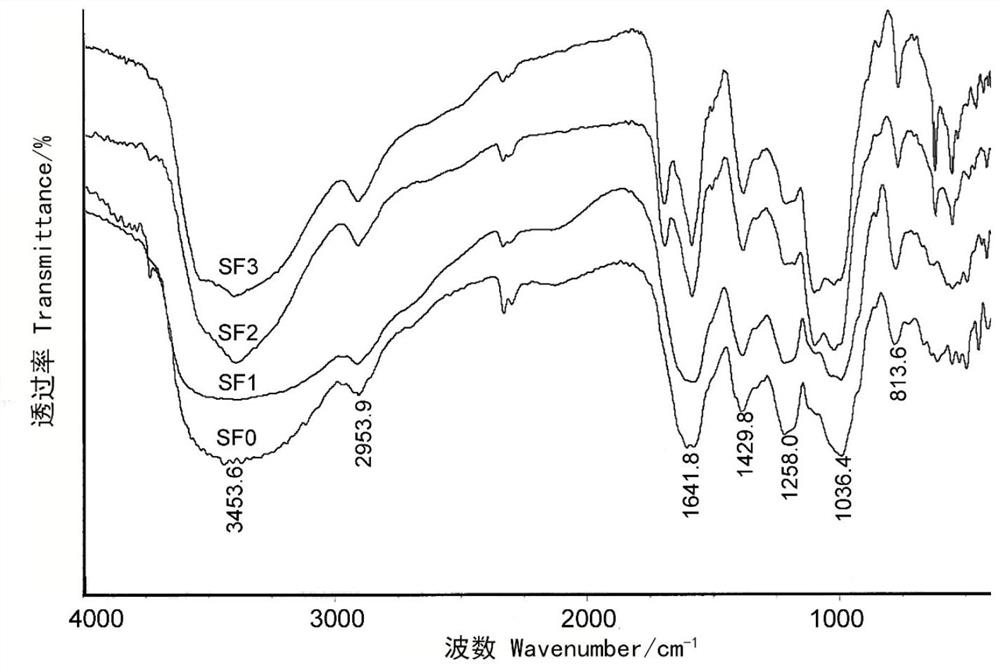

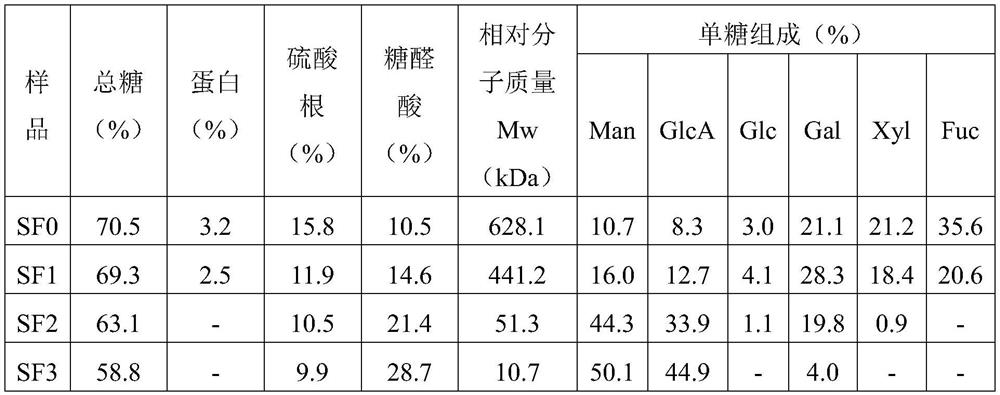

[0047] Crude fucoidan was chromatographed on Q-Sepharose Fast Flow column, eluted with deionized water and NaCl solution (0.5, 1, 1.5, 2mol / L) at a gradient of 3mL / min, each tube was connected with 6mL, each flow Connect 60 tubes, collect the main polysaccharide eluted with 1.5mol / L NaCl, and purify it with Sepharose 4B Fast Flow column to obtain Artemisia fucoidan, which is named SF0.

[0048] SF0 was treated with 0.1mol / LTFA at 60°C for 3h. Low-molecular-weight oligosaccharides were remo...

Embodiment 2

[0050] Distill the sea wormwood powder with 95% ethanol at 90°C for 5h (twice) to remove the lipid and dry the residue, pulverize; the obtained powder was extracted with 75°C hot water at a solid-liquid ratio of 1:40 for 2h (repeat 3 times), centrifuge, collect all supernatant, concentrate; add CaCl 2 to 3 mol / L, the sedimentation temperature was 4°C, stood for 12 hours, then centrifuged, dialyzed, concentrated and freeze-dried the supernatant to obtain crude sea wormwood fucoidan.

[0051] Crude fucoidan was chromatographed on Q-Sepharose Fast Flow column, eluted with deionized water and NaCl solution (0.5, 1, 1.5, 2mol / L) at a gradient of 3mL / min, each tube was connected with 6mL, each flow Connect 60 tubes. The main polysaccharide eluted with 1.5 mol / L NaCl was collected and purified with a Sepharose 4B Fast Flow column to obtain sea wormwood fucoidan, which was named SF0.

[0052] SF0 was treated with 0.15mol / LTFA at 55°C for 2h. Low-molecular-weight oligosaccharides we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com