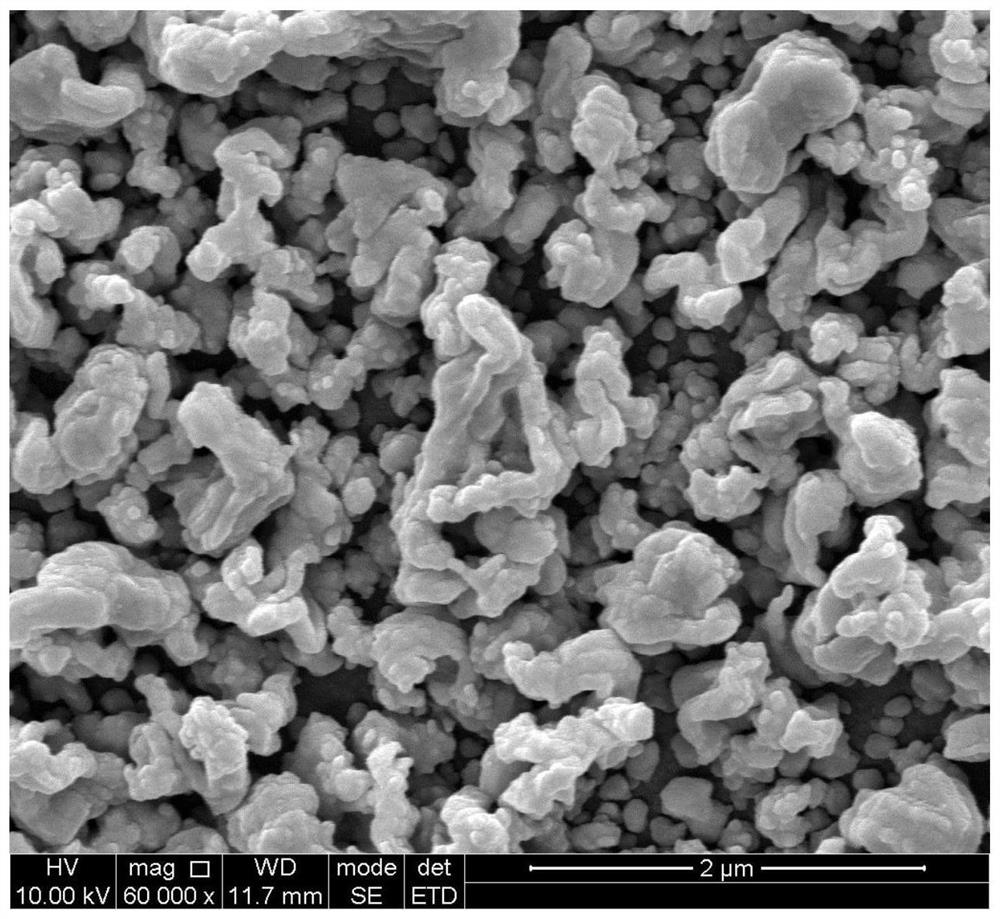

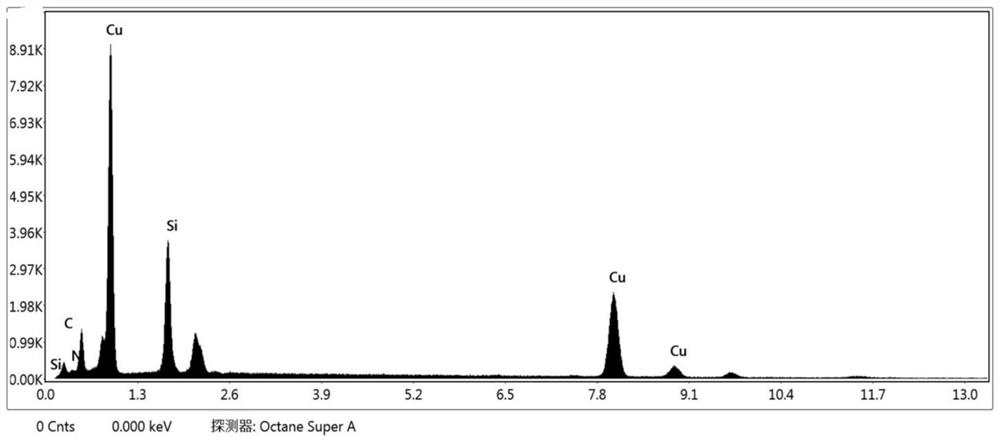

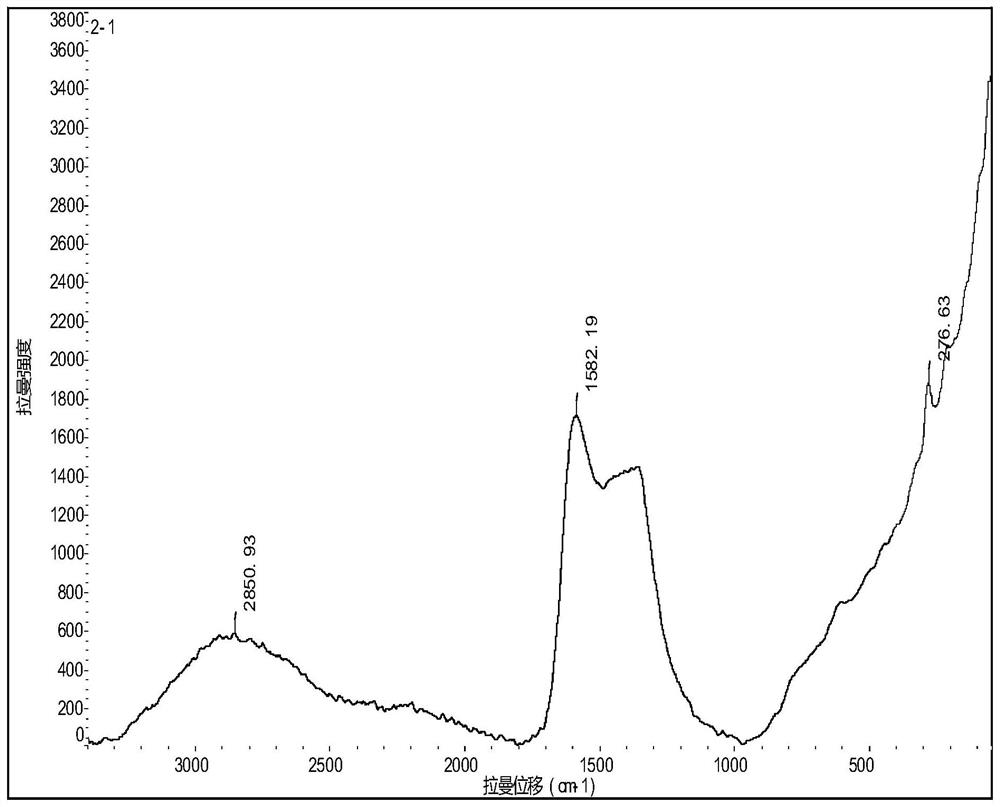

Porous Cu-SiC composite film and preparation method thereof

A composite film and substrate technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of volume fraction, distribution and particle size that are difficult to control, and achieve tight combination, simple process, and pore size fine uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a porous Cu-SiC composite membrane, comprising the steps of:

[0031] S1. Prepare the substrate: take the monocrystalline silicon wafer and put it in absolute ethanol, clean it with an ultrasonic cleaner for 15 minutes, then wash it in deionized water for 15 minutes, dry it in an oven, and place the treated substrate on the substrate. on the stage;

[0032] S2. Target installation: install the Cu target with a mass percentage concentration of 99.99% and the SiC target with a mass percentage concentration of 99.99% respectively in the DC sputtering and radio frequency sputtering target positions in the vacuum chamber, and first use a mechanical pump to evacuate to 20Pa. Then use a molecular pump to evacuate, so that the vacuum degree of the vacuum chamber reaches 4.0×10 -4 Pa;

[0033] S3, preparing Cu 3 N-SiC composite film: Introduce argon gas with a volume percentage concentration of 99.99% into the S2 medium vacuum chamber, the flow rate is ...

Embodiment 2

[0038] A method for preparing a porous Cu-SiC composite membrane, comprising the steps of:

[0039] S1. Prepare the substrate: take the steel sheet and put it in absolute ethanol, clean it with an ultrasonic cleaner for 15 minutes, then wash it in deionized water for 15 minutes, dry it in an oven, and place the processed substrate on the substrate table superior;

[0040]S2. Target installation: install the Cu target with a mass percentage concentration of 99.99% and the SiC target with a mass percentage concentration of 99.99% respectively in the DC sputtering and radio frequency sputtering target positions in the vacuum chamber, and first use a mechanical pump to evacuate to 20Pa. Then use a molecular pump to evacuate, so that the vacuum degree of the vacuum chamber reaches 4.0×10 -4 Pa;

[0041] S3, preparing Cu 3 N-SiC composite film: Introduce argon gas with a volume percentage concentration of 99.99% into the S2 medium vacuum chamber, the flow rate is 20SCCM, adjust t...

Embodiment 3

[0046] A method for preparing a porous Cu-SiC composite membrane, comprising the steps of:

[0047] S1. Prepare the substrate: take the monocrystalline silicon wafer and put it in absolute ethanol, clean it with an ultrasonic cleaner for 10 minutes, then wash it in deionized water for 10 minutes, dry it in an oven, and place the treated substrate on the substrate. on the stage;

[0048] S2. Target installation: install the Cu target with a mass percentage concentration of 99.999% and the SiC target with a mass percentage concentration of 99.9% respectively in the DC sputtering and radio frequency sputtering target positions in the vacuum chamber, and first use a mechanical pump to evacuate to 20Pa. Then use a molecular pump to evacuate, so that the vacuum degree of the vacuum chamber reaches 1.0×10 -4 Pa;

[0049] S3, preparing Cu 3 N-SiC composite film: Introduce argon gas with a volume percentage concentration of 99.999% into the S2 medium vacuum chamber, the flow rate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com