Polyimide modified polyurethane adhesive and preparing method thereof

A polyurethane adhesive, polyimide technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the complexity of the preparation process of polyimide modified polyurethane adhesives, Obstructing the industrial production process of high-performance adhesives, increasing the cost of adhesive preparation, etc., to achieve the effect of broadening the use temperature range, improving high temperature resistance and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: A polyimide-modified polyurethane adhesive made of the following raw materials in parts by weight: 40 parts of polytetrahydrofuran diol (molecular weight 2000), 8.7 parts of 4,4'-diphenylmethane diisocyanate , 2.2 parts of pyromellitic dianhydride, 0.8 parts of dimethyl silicone oil, 0.06 parts of triethylenediamine, 20 parts of diisooctyl phthalate, 0.05 parts of p-toluenesulfonyl isocyanate, γ- 0.05 parts of aminopropyltriethoxysilane, 0.05 parts of 3,5-di-tert-butyl-4-hydroxyphenylpropanoic acid octadecanoate.

[0043] Concrete preparation steps are:

[0044] 1) Weigh 400g of polytetrahydrofuran diol with a molecular weight of 2000 and put it into a 1L reaction kettle, stir and heat to 100°C, and vacuumize and dehydrate for 4 hours;

[0045] 2) Add 8 g of simethicone oil and 22 g of pyromellitic dianhydride to the polytetrahydrofuran diol cooled to room temperature after dehydration treatment, and mechanically stir evenly;

[0046]3) Add 87g of 4,4'-diph...

Embodiment 2

[0049] Embodiment 2: A polyimide modified polyurethane adhesive is made of the following raw materials in parts by weight: 35 parts of tetrahydrofuran-ethylene oxide copolymerized glycol (molecular weight 3000), 12.2 parts of hexamethylene diisocyanate, 3 , 5 parts of 3′,4,4′-biphenyltetraacid dianhydride, 1.6 parts of dimethyl silicone oil, 0.12 parts of triethylenediamine, 35 parts of diisooctyl phthalate, 35 parts of orthoformic acid 0.13 parts of ethyl ester, 0.3 parts of γ-(methacryloyloxy)propyltrimethoxysilane, and 0.08 parts of isooctyl 3,5-di-tert-butyl-4-hydroxyphenylpropionate.

[0050] Concrete preparation steps are:

[0051] 1) Weigh 350g of tetrahydrofuran-ethylene oxide copolyglycol with a molecular weight of 3000 and put it into a 2L reaction kettle, stir and heat to 95°C, and vacuumize and dehydrate for 4 hours;

[0052] 2) Add 16 g of simethicone oil and 50 g of 3,3′,4,4′-biphenyltetraacid dianhydride to the tetrahydrofuran-ethylene oxide copolyethylene glyc...

Embodiment 3

[0056] Embodiment 3: Comprehensive performance test of adhesive force.

[0057] Shear strength is measured according to GB7124-86;

[0058] Peel strength is measured according to GB / T7122-1996.

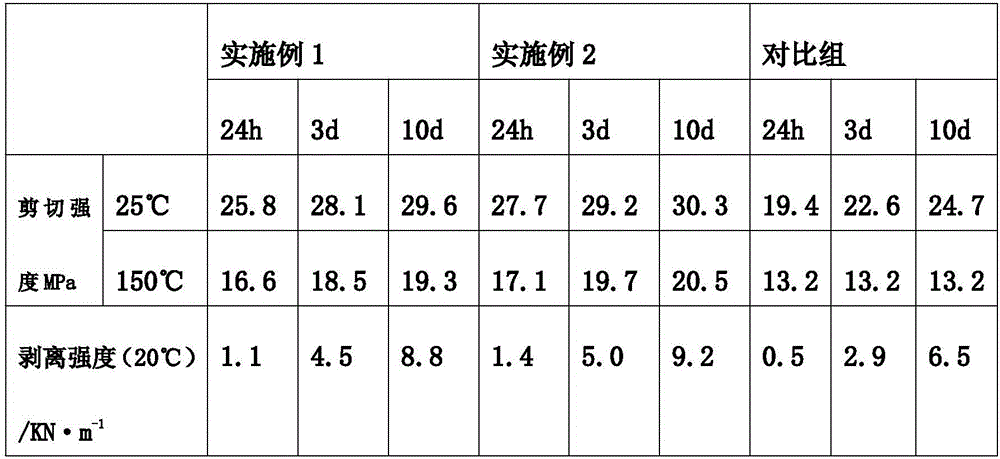

[0059] Take the adhesives of Examples 1 and 2, and then take the polyurethane adhesive commonly used in the industry as a comparison group, and measure the shear strength and peel strength after curing at room temperature for 24 hours, 3 days and 10 days, see Table 1.

[0060] Table 1 Adhesive adhesion test

[0061]

[0062] It can be seen from Table 1 that the shear strength of the adhesives of Example 1 and Example 2 is significantly better than that of the comparison group at 25°C, and the shear strength is also much better than that of the comparison group at 150°C, and the effect is very good. significantly. And the peel strength of Example 1 and Example 2 is also much better than that of the comparison group. It can be seen that the present invention not only has superior...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com