Recycling treatment method for high-salt gold smelting wastewater

A wastewater circulation and treatment method technology, which is applied in metallurgical wastewater treatment, water/sewage treatment, neutralization water/sewage treatment, etc., can solve the problems of high evaporation energy consumption, high salinity of production wastewater, poor biodegradability, etc., and achieve Reduce production costs, increase production costs, and achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

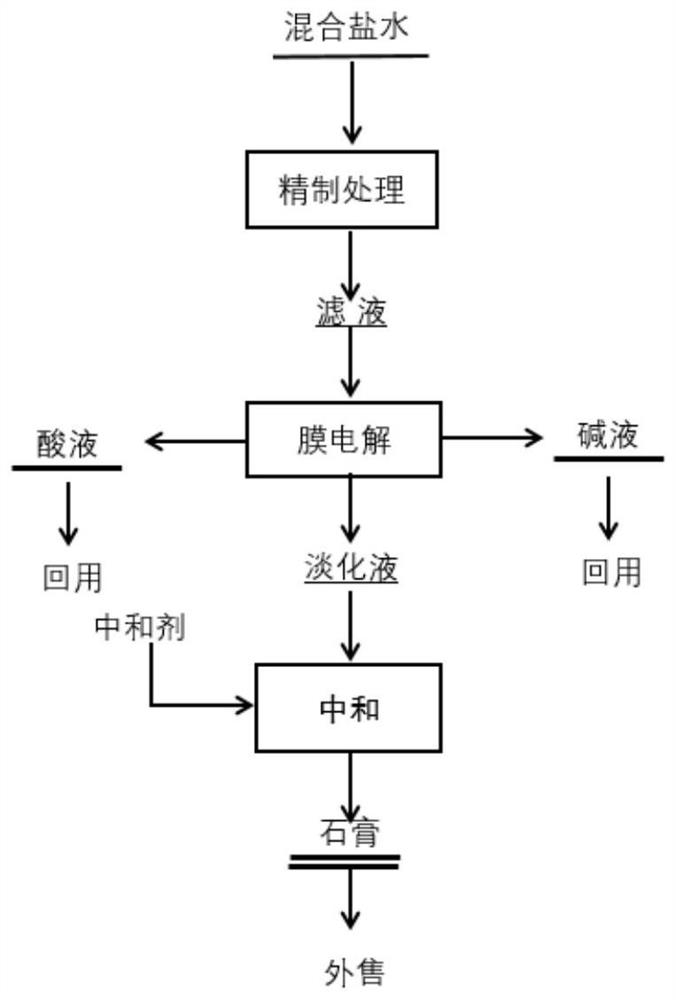

[0024] A gold smelting wastewater, the daily comprehensive brine discharge is 15m 3 / d, wherein the content of sodium chloride is 35g / L, sodium nitrate is 28g / L, and sodium sulfate is 18g / L. like figure 1 As shown in the figure, after the brine is refined and filtered, it is pumped into the bipolar membrane electrolysis system for treatment, and the current density is controlled to 450A / m 2 , the electrolysis time is 3.5h. The anion membrane used in the bipolar membrane electrolysis system is a special anion exchange membrane that only allows monovalent anions to pass through. Under the action of an electric field, monovalent anions chloride ions and nitrate ions can pass through the ion membrane, while divalent sulfate ions cannot pass through the ion membrane. membrane. Acid receiving solution 9-15m 3 / d, the initial mass concentration is 1.0%, and the alkali receiving solution is 12-18m 3 / d, the initial mass concentration is 0.8%, acid (concentration 6%) and alkali (c...

Embodiment 2

[0026] A gold smelting wastewater in Fujian has a daily comprehensive brine discharge of 20-25m 3 / d, wherein the content of sodium chloride is 15g / L, sodium nitrate is 35g / L, and sodium sulfate is 25g / L. like figure 1 As shown in the figure, after the brine is refined and filtered, it is pumped into the bipolar membrane electrolysis system for treatment, and the current density is controlled to 1000A / m 2 , the electrolysis time is 3.0h. The anion membrane used in the bipolar membrane electrolysis system is a special anion exchange membrane that only allows monovalent anions to pass through. Under the action of an electric field, monovalent anions chloride ions and nitrate ions can pass through the ion membrane, while divalent sulfate ions cannot pass through the ion membrane. membrane. Acid receiving solution 12-20m 3 / d, the initial mass concentration is 2.0%, and the alkali receiving solution is 16-30m 3 / d, the initial mass concentration is 2.0%, the electrolysis prod...

Embodiment 3

[0028] A gold smelting wastewater in the north produces a comprehensive brine discharge of 50m per day 3 / d, wherein the content of sodium chloride is 40g / L, sodium nitrate is 30g / L, and sodium sulfate is 12g / L. like figure 1 As shown in the figure, after the brine is refined and filtered, it is pumped into the bipolar membrane electrolysis system for treatment, and the current density is controlled to 600A / m 2 , the electrolysis time is 5.0h. The anion membrane used in the bipolar membrane electrolysis system is a special anion exchange membrane that only allows monovalent anions to pass through. Under the action of an electric field, monovalent anions chloride ions and nitrate ions can pass through the ion membrane, while divalent sulfate ions cannot pass through the ion membrane. membrane. Acid receiving solution 40m 3 / d, the initial mass concentration is 0.5%, and the alkali receiving solution is 60m 3 / d, the initial mass concentration is 0.5%, the electrolysis prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com