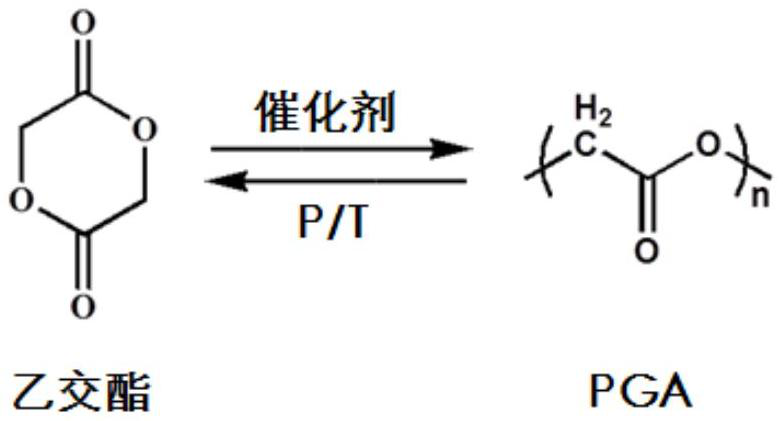

Catalyst composition for preparing polyglycolide and preparation method of polyglycolide

A polyglycolide and catalyst technology, applied in the field of polyglycolide preparation, can solve the problems of high residual monomer content, decreased mechanical properties, etc., and achieve the advantages of improving intrinsic viscosity and weight average molecular weight, reducing content and achieving good technical effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Preparation of Titanium Complex A

[0058] In a reactor equipped with a stirrer, a condenser and a thermometer, add 18.6 grams (0.3 moles) of ethylene glycol, slowly drop 28.4 grams (0.1 moles) of tetraisopropyl titanate into the reactor, and precipitate a white precipitate , reacted at 80°C for 3 hours, centrifuged the product, washed the residue three times with distilled water, and dried the product in vacuum at 70°C to obtain a white powdery substance. Put the dried white powdery substance in a reactor equipped with a stirrer, a condenser and a thermometer, add 12 grams (0.2 moles) of isopropanol and react at 60°C for 3 hours to obtain a colorless transparent liquid, which is titanium Complex A.

[0059] Preparation of phosphorus complex B

[0060] In a reactor equipped with a stirrer, a condenser and a thermometer, add 14.0 grams (0.1 moles) of trimethyl phosphate and 21.6 grams (1.2 moles) of water, and drop 31.0 grams (0.5 moles) of ethylene glycol into the rea...

Embodiment 2

[0064] Preparation of Titanium Complex C

[0065] In a reactor equipped with a stirrer, a condenser and a thermometer, add 18.6 grams (0.3 moles) of ethylene glycol, slowly drop 28.4 grams (0.1 moles) of tetraisopropyl titanate into the reactor, and precipitate a white precipitate , reacted at 100°C for 2 hours, centrifuged the product, washed the residue three times with distilled water, and dried the product in vacuum at 70°C to obtain a white powdery substance. Put the dried white powdery substance in a reactor equipped with a stirrer, a condenser and a thermometer, add 18.0 grams (0.3 moles) of isopropanol and react at 80 ° C for 4 hours to obtain a colorless transparent liquid, which is titanium Complex C.

[0066] Preparation of polyglycolide

[0067] 1000 grams of glycolide is added in the there-necked flask, and titanium complex C (based on the mass of glycolide monomer, the weight of the titanium atom is 140 mg / kg) is added under the molten state of glycolide, and t...

Embodiment 3

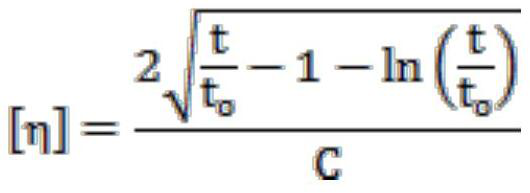

[0069] Preparation of polyglycolide

[0070] 1000 grams of glycolide is added in the there-necked flask, and titanium complex C (based on the mass of glycolide monomer, the weight of the titanium atom is 80 mg / kg) is added under the molten state of glycolide, and the phosphorus complex B (based on the mass of glycolide monomer, the weight of phosphorus atom is 20mg / kg), mixed at 83°C for 8 minutes, after the mixture was cooled and pulverized, it was continuously added to the twin-screw extruder through an autosampler for ring opening Polymerization reaction, reaction temperature 230°C, polymerization residence time 15 minutes, continue to enter the single-screw extruder for on-line removal of residual monomers, single removal temperature 175°C, single removal residence time 6 minutes, to obtain continuously and stably discharged polymer glycolide. The measured intrinsic viscosity of polyglycolide is 1.91dL / g, the weight average molecular weight is 219000, the relative molecul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com