Functional silane macromolecular polymer and preparation method thereof, and additive and application thereof

A technology of macromolecules and polymers, applied in the directions of additives, organic silicon compounds, chemical instruments and methods, etc., can solve the problem that the hardness of the coating cannot meet the demand, and achieve the improvement of hardness and salt spray resistance, etc., products are easy to obtain, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The method of preparation of the silane macromonomer polymer comprises the steps of:

[0028] The silane coupling agent was mixed with a solvent, wherein the silane coupling agent may be selected methacryloxypropyl trimethoxy silane, methacryloxy propyl methyl dimethoxy silane, methyl acryloxy propyl triethoxy silane, methacryloxy propyl methyl diethoxy silane, methacryloxy propyl triisopropoxysilane, 3 (2,3- oxo propoxy) propyl trimethoxysilane, 3 (2,3-epoxy propoxy) propyl triethoxysilane, 3 (2,3-epoxy propoxy) propyl methyl dimethoxysilane , 3 (2,3-epoxy propoxy) propyl methyl diethoxy silane, vinyltriethoxysilane, vinyltrimethoxysilane, vinyltris (methoxyethoxy) silane one or more; silane coupling agent and water molar ratio is preferably 1: 3-1: 4, a silane coupling agent and a solvent mass ratio is preferably 1: 2-1: 3;

[0029] After mixing stir polymerization inhibitor, the polymerization inhibitor mixed esters should be used, and a silane coupling agent added in an...

Embodiment 1

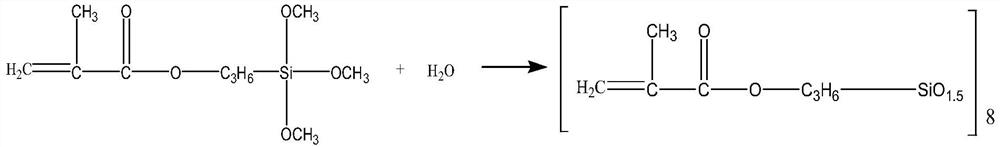

[0034] To 1000ml three-necked flask equipped with a stirrer was charged with 3-methacryloxypropyl trimethoxysilane and 248g 496g of methanol was added 0.15g polymerization inhibitor, stir, added dropwise 100g methanol / water / hydrochloric acid solution the control dropping of 1d / s; the addition was complete the reaction at room temperature 8h, after the reaction under reduced pressure to collect 550g methanol, 200g of toluene was added at 100 deg.] C for 3h, with tetramethylammonium hydroxide solution, the solution was adjusted to PH 7, the solvent was evaporated under reduced pressure to 306g, the silane macromonomer polymer was filtered to give 180g; one of the reaction equation of the preparation process is as follows:

[0035]

[0036] The silane macromonomer polymer product a colorless transparent viscous liquid, yield = actual product quality by / * 100% theoretical product mass calculated yield of 95% and a viscosity of 1000mm 2 / S, average molecular weight of 1860. ...

Embodiment 2

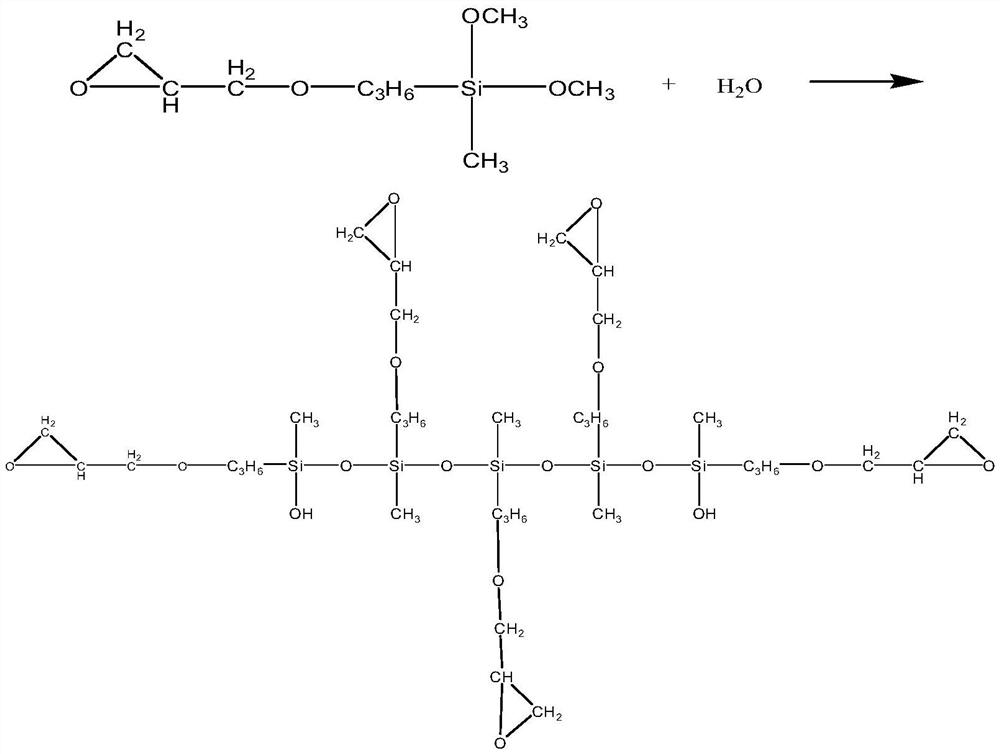

[0039] To 1000ml three-necked flask equipped with a stirrer was charged with 220g of 3 (2,3-epoxy propoxy) propyl methyl dimethoxy silane and 475g of methanol was added 0.15g polymerization inhibitor, stir, a solution of 100g methanol / water / hydrochloric acid solution, the control of dropping 1d / s; the addition was complete the reaction at room temperature, 6h, after the reaction under reduced pressure to collect 520g methanol, 200g of isopropanol was added at 80 deg.] C the reaction was refluxed for 2.5h, treated with potassium hydroxide the solution was adjusted to PH 6, 295 g of solvent was distilled off under reduced pressure, filtered to give 167 g of a silane macromonomer polymer; one of the reaction equation of the preparation process is as follows:

[0040]

[0041] The silane macromonomer polymer product a colorless transparent viscous liquid, yield = actual product quality by / * 100% theoretical product mass calculated yield of 92%, a viscosity of 500mm 2 / S, av...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com