Plastic for antenna oscillator

An antenna vibrator and plastic technology, applied in the field of antennas, can solve the problems of base station antenna performance deterioration, uneven surface morphology, large surface roughness, etc., to eliminate the influence of carbonization, low surface roughness, and good shape consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] This embodiment provides a kind of plastic, comprises the component of following parts by weight:

[0085] Liquid crystal polyester: 45 parts

[0086] Titanium dioxide: 35 parts

[0087] Silica microspheres: 10 parts

[0088] Flat fiberglass: 10 parts

[0089] The D50 of the silica microspheres is 5 μm. The flat glass fiber is alkali-free glass fiber with a section thickness of 7 μm.

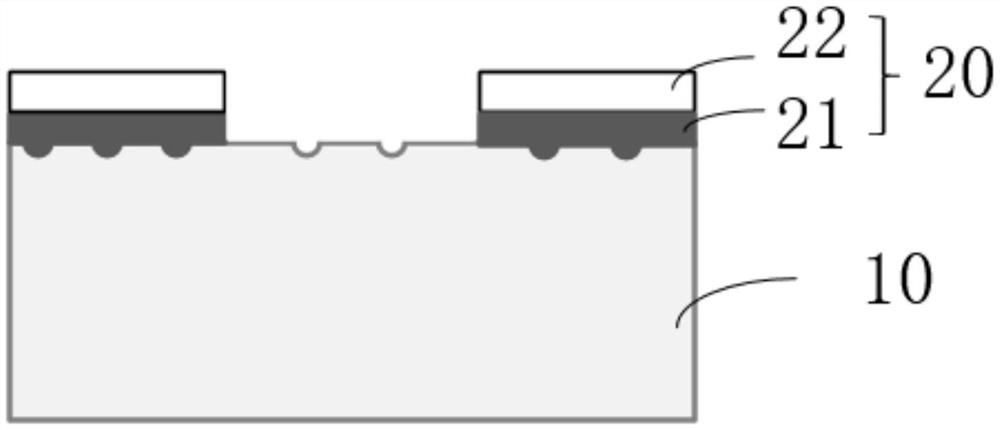

[0090]The plastic used in this embodiment is titanium dioxide. On the one hand, titanium dioxide has strong reflectivity to laser light, which can significantly reduce or eliminate the influence of carbonization of plastic substrates caused by laser processing; at the same time, because titanium dioxide has a high dielectric constant and low dielectric loss, it can As a dielectric modifier to obtain high dielectric and low loss materials. The components of liquid crystal polyester, silica microspheres and flat glass fibers can be chemically etched, and after etching, a stable low-rou...

Embodiment 2

[0093] This embodiment provides a kind of plastic, comprises the component of following parts by weight:

[0094] Liquid crystal polyester: 61 parts

[0095] Titanium dioxide: 6 parts

[0096] Silica microspheres: 23 parts

[0097] Flat fiberglass: 10 parts

[0098] The D50 of the silica microspheres is 5 μm. The flat glass fiber is alkali-free glass fiber with a section thickness of 7 μm.

[0099] The material of this embodiment has characteristics of lower dielectric constant, low dielectric loss, low cost, low PIM, and high strength.

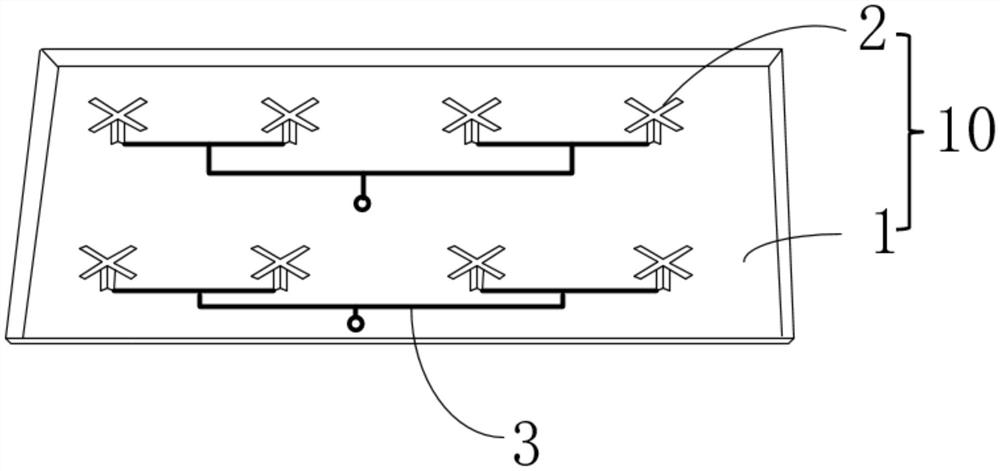

[0100] The plastic tensile strength of this embodiment is 125Mpa. The plastic of this embodiment is injection molded into a plastic plate, and then a chemical corrosion solution is used to corrode the plastic plate, so that the surface of the plastic plate forms a rough surface with a surface roughness Ra of 2.6 μm, and then the plastic plate is plated with grounding layer metal and Microstrip line, get simplified microstrip transmissio...

Embodiment 3

[0102] This embodiment provides a kind of plastic, comprises the component of following parts by weight:

[0103] Liquid crystal polyester: 45 parts

[0104] Titanium dioxide: 35 parts

[0105] Silica microspheres: 20 parts

[0106] The D50 of the silica microspheres is 5 μm.

[0107] The material in this embodiment has the characteristics of relatively high dielectric constant, low dielectric loss, low cost, low PIM, and high strength.

[0108] The tensile strength of the plastic in this embodiment is 118Mpa. The plastic of this embodiment is injection molded into a plastic plate, and then a chemical corrosion solution is used to corrode the plastic plate, so that the surface of the plastic plate forms a rough surface with a surface roughness Ra of 2.5 μm, and then the ground layer metal and Microstrip line, get simplified microstrip transmission line slab. Tested with the same method as in Example 1, the average value of the third-order PIM of the material in this examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com