Polymer emulsifier, and preparation method and application thereof

A polymer emulsifier and esterification technology, applied in chemical instruments and methods, coatings, anti-corrosion coatings, etc., can solve problems that affect the storage stability of resins or coatings, the hydrophilicity of resins cannot be adjusted, and restrict the application of paints, etc. , to achieve excellent emulsifying ability, strong affinity, and improve the effect of anti-corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

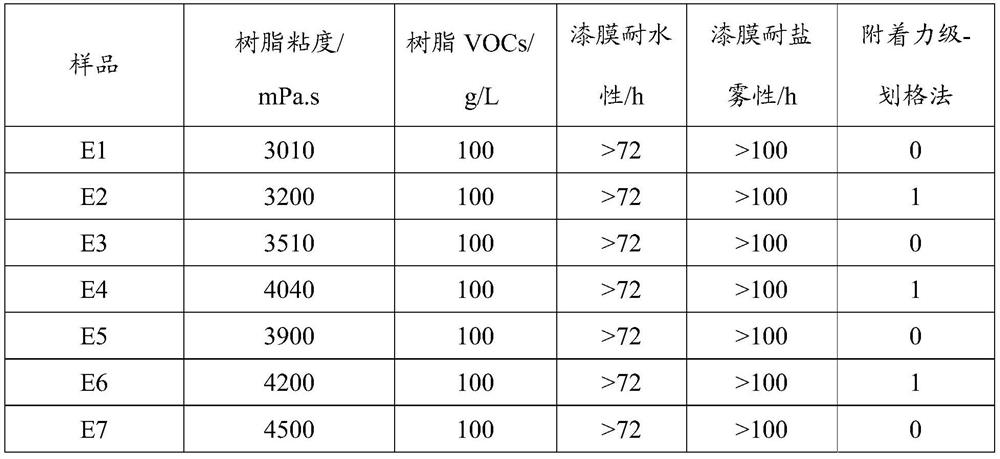

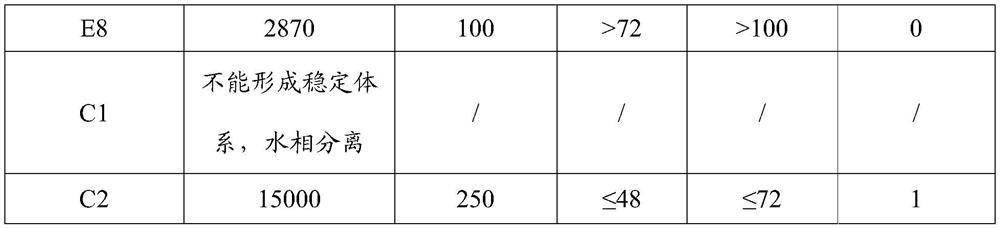

Examples

preparation example Construction

[0024] First, the invention provides a kind of preparation method of polymer emulsifier, comprises the steps:

[0025] S1 Fatty acid, vegetable oleic acid and polyhydric alcohol are blended, and the first intermediate is obtained through esterification and dehydration;

[0026] S2 Add tristyrylphenol polyoxyethylene-polyoxypropylene block polyether to the first intermediate for blending, and then phosphorylate to obtain the second intermediate;

[0027] The second intermediate of S3 is neutralized by amine to obtain a polymer emulsifier.

[0028] specifically,

[0029] S1 Fatty acid, vegetable oleic acid and polyols are blended, nitrogen gas is introduced, the temperature is raised to 180-220°C and heat preservation treatment is carried out, the first intermediate is obtained by esterification and dehydration, and the temperature is lowered to 50-75°C.

[0030] S2 Add tristyrylphenol polyoxyethylene-polyoxypropylene block polyether to the first intermediate for blending, ble...

Embodiment 1

[0045] Add 0.5 mol of catalpa fatty acid, 1.5 mol of oleic acid, and 1 mol of trimethylolpropane into the reactor, pass through nitrogen protection, heat up to 200°C for dehydration and esterification reaction until the acid value is less than 1mgKOH / g, cool down to 60°C; add 1mol Tristyrylphenol polyoxyethylene-polyoxyethylene propylene block polyether (EO:PO=16:2), stir for 30min; add 1mol phosphorus pentoxide in 3 batches, keep warm at 60°C for 2h; add 1mol Deionized water, continue to keep warm for 1h. The temperature was lowered to 40° C., and 1 mol of dimethylethanolamine was added for neutralization, so that the pH value was 7-8, and polymer emulsifier sample 1 was obtained.

Embodiment 2

[0047] Add 1.5 mol of catalpa fatty acid, 0.5 mol of oleic acid, and 1 mol of trimethylolpropane into the reactor, raise the temperature to 200°C, pass through nitrogen protection, dehydrate and esterify until the acid value is less than 1mgKOH / g, cool down to 60°C; add 1mol Tristyrylphenol polyoxyethylene-polyoxypropylene block polyether (EO:PO=16:2), stirred for 30min; added 1mol phosphorus pentoxide in 3 batches, and kept the reaction at 60°C for 2h; added 1mol to Ionized water, continue to keep warm for 1h. Cool down to 40°C, add 1mol dimethylethanolamine for neutralization, make the pH value 7-8, and obtain polymer emulsifier sample 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com