A kind of composite gas cylinder and its preparation method

A technology of composite materials and composite material layers, applied in the field of composite material pressure-resistant containers, can solve the problems of poor chemical stability, dependence on imports, and poor weather resistance, and achieve low production costs, reduced production costs, and extensive acid and alkali resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

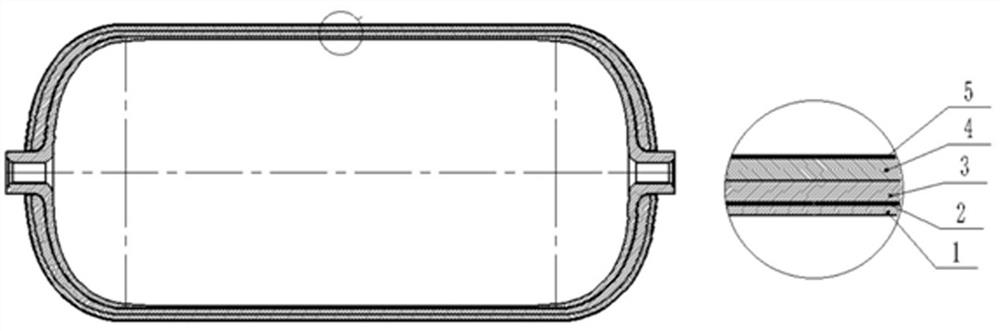

[0051] Such as figure 1 As shown, the composite gas cylinder described in this embodiment has a working pressure of 35 MPa, a volume of 50 L, and a cylindrical inner tank. Including set up in order from inside to outside:

[0052] Stainless steel liner 1;

[0053] The adhesive transition layer 2 has a thickness of 0.5mm. The preparation raw materials of the adhesive transition layer include glass fiber cloth and adhesive, and the preparation raw materials of the adhesive include epoxy resin with a mass ratio of 100:90:0.8 , Methyltetrahydrophthalic anhydride, N, N-dimethylbenzylamine;

[0054] The carbon fiber composite material layer 3 has a thickness of 2.5mm. The raw materials for the preparation of the carbon fiber composite material layer include a bismaleimide resin matrix (the measured glass transition temperature is greater than 250°C) and Toray T700SC-1200K carbon fiber reinforced material (wire Density 800tex, retest tensile strength 5120MPa), wherein, the mass pe...

Embodiment 2

[0067] For the composite gas cylinder of this embodiment, the rest of the preparation steps are the same as in Example 1, except that the raw materials for the preparation of the adhesive in the bonding transition layer 2 are epoxy resin, methyl Tetrahydrophthalic anhydride, N,N-dimethylbenzylamine.

[0068] The composite gas cylinder has passed the air tightness test of 35MPa and the water pressure test of 52.5MPa. And after -60°C low temperature test and 180°C high temperature test, the air tightness test is qualified, and it has passed the low temperature test and high temperature test.

Embodiment 3

[0070] For the composite gas cylinder of this embodiment, the rest of the preparation steps are the same as those in Example 1, except that in step S3, the basalt fiber reinforcement material impregnated with bismaleimide resin matrix is sequentially rotated at 89° / 20° / 89° / 65° / 10° / 89° / 15° / 89° / 20° / 89° / 65° / 10° / 89° / 15° / 89° / 20° / 89° / 60° / 10° / 89 ° / 15° / 89° / 10° / 89° hoop winding and helical winding are alternately wound to the outer surface of the carbon fiber composite material layer.

[0071] The composite gas cylinder has passed the air tightness test of 35MPa and the water pressure test of 52.5MPa. And after -60°C low temperature test and 180°C high temperature test, the air tightness test is qualified, and it has passed the low temperature test and high temperature test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com