Self-finishing freeze-dried polishing wheel as well as preparation method and application thereof

A freeze-drying and drying technology, which is applied in the field of self-repairing freeze-drying polishing wheels and its preparation, can solve the problems of unstable processing quality, easy fragmentation, difficult processing, etc., and achieve the effect of high-quality polishing and large elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 20g of sodium alginate, 5g of xanthan gum, and 600g of water into a beaker, stir at room temperature at 550rpm for 2h, and make mixture 1;

[0021] In addition, add 600g of water, 50g of nylon powder, 120g of pulp and 50g of W5 diamond abrasive into a beaker, stir at room temperature for 30min at 550rpm, and prepare mixture 2;

[0022] Add 5g of calcium chloride to 1Kg of water to obtain a calcium salt solution;

[0023] Add mixture 2 to mixture 1 at room temperature, stir at 1000 rpm for 8 hours, pour into a mold after the stirring is completed, then soak the mold in calcium salt solution for 120 minutes, take it out, and obtain a gel polishing body;

[0024] Put the gel polishing body into a vacuum drying oven, dry it in vacuum at 50°C for 3 hours, and the vacuum degree is 1000Pa; after taking it out, freeze it at -18°C for 6 hours, then freeze-dry it, drop it to -70°C for 5 hours, and then keep it at -70 °C freeze-drying time 24h, obtain freeze-dried polishing b...

Embodiment 2

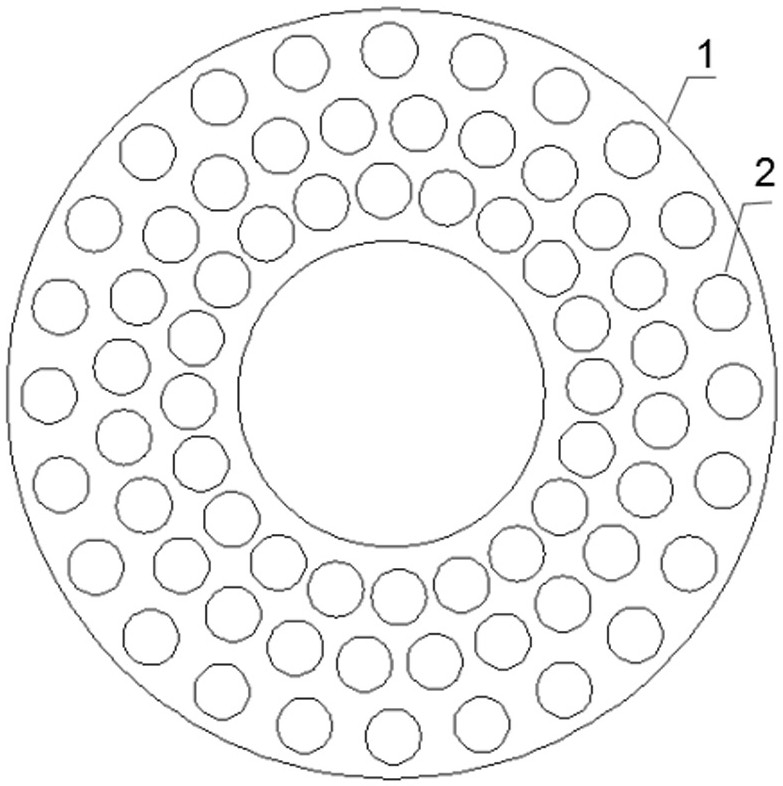

[0027] Use conventional grinding wheel structure glue (such as epoxy AB glue) to glue the freeze-dried polishing block 2 on the existing stainless steel substrate 1, see figure 1 , the freeze-dried gel block is pasted on the surface of the stainless steel substrate to form a self-repairing freeze-dried polishing wheel.

Embodiment 3

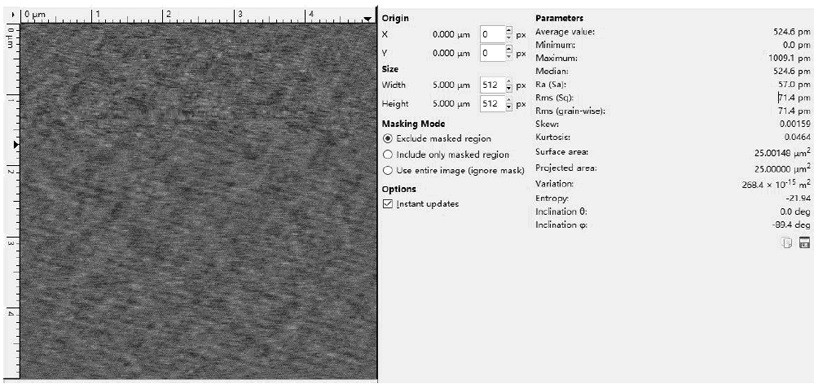

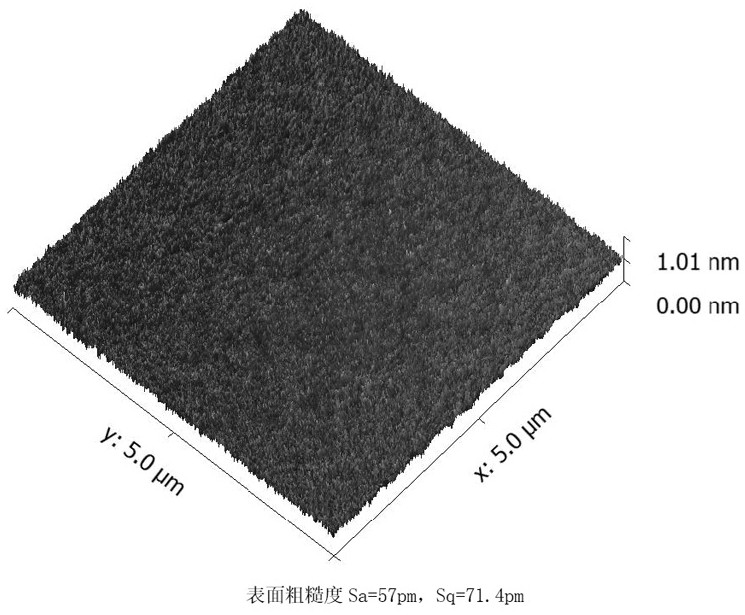

[0029] Use the self-dressing freeze-dried polishing wheel of Example 2 to process a 2-inch diamond wafer (Sa is 0.4nm), the base is a Heriot 13B polishing machine, the speed is 50rpm, the pressure is 200kg, and the time is 2h. After polishing, the wafer Surface roughness Sa is 57pm, Sq is 71.4pm, see the results figure 2 and image 3 . The thickness change of the wafer before and after polishing is measured by a thickness gauge to calculate the material removal rate, which is 2.55nm / min.

[0030] For the diamond wafer whose Sa has reached 0.4nm, it is difficult to further polish the polishing method used in the existing industrial production. The applicant researched a method that can further reduce the surface roughness of the diamond wafer, but it cannot reach below 150pm, and the processing efficiency It is extremely low, and the material removal rate in the polishing stage is 0.02nm / min; the self-conditioning freeze-dried polishing wheel of the present invention is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com