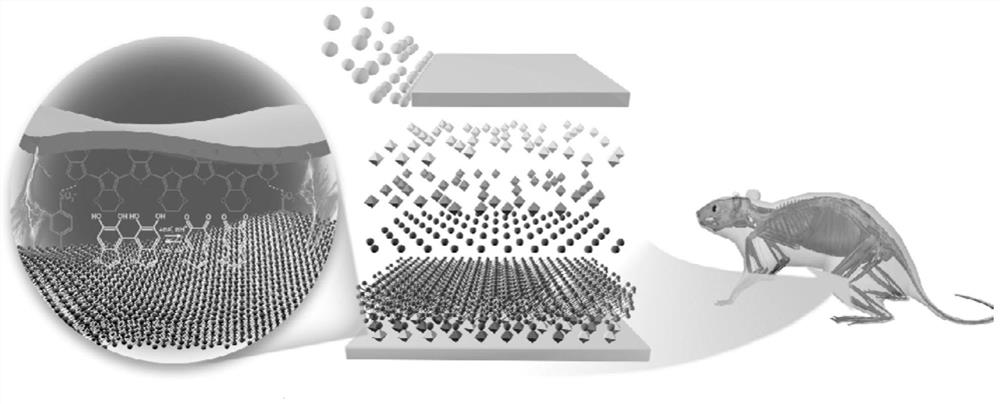

High-stability self-linking MXene nanosheet, and preparation method and application thereof

A nanosheet, selected technology, applied in the field of biological materials, can solve the problems that can only be used for plating, the loss of the stability of the polydopamine layer, the undisclosed preparation of conductive polymers, etc., to achieve stable electrical properties, Excellent tissue adhesion ability and the effect of reducing tissue diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

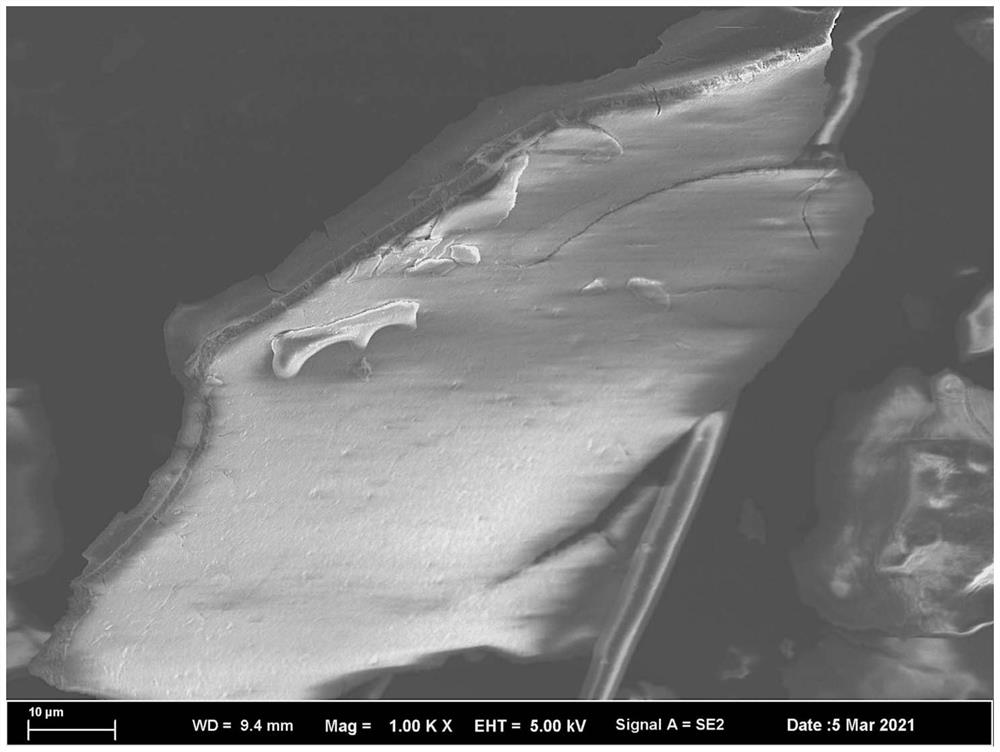

[0069] The preparation of embodiment 1 modified MXene material

[0070] 1) Add 3g Ti 3 AlC 2 The powder was slowly dipped into a Teflon beaker filled with 40 mL of HF aqueous solution and etched at room temperature for 48 h. The resulting suspension was then transferred to a centrifuge tube and centrifuged. The wet pellet was washed with deionized water and centrifuged several times. Accordion-like two-dimensional MXene material Ti obtained by HF acid selective etching 3 C 2 .

[0071] 2) After decanting the liquid in the previous step, add a small amount of dilute NaOH solution dropwise to the centrifuge tube, transfer the solution to a beaker, and stir for 2 hours. The product was centrifuged and washed several times with a large amount of deionized water until the pH of the top liquid was 7-8 to obtain MXene-N(Na + intercalated MXene materials). Under this structure, Na ions are intercalated between MXene sheets, and the interlayer spacing of MXene will be enlarged, w...

Embodiment 2

[0075] The preparation of embodiment 2 modified MXene materials

[0076] 1) Put 4g Ti 3 AlC 2 The powder was slowly dipped into a Teflon beaker filled with 40 mL of HF aqueous solution and etched at room temperature for 48 h. The resulting suspension was then transferred to a centrifuge tube and centrifuged. The wet pellet was washed with deionized water and centrifuged several times.

[0077] 2) After decanting the liquid in the previous step, add a small amount of dilute NaOH solution dropwise to the centrifuge tube, transfer the solution to a beaker, and stir for 2 hours. The product was centrifuged and washed several times with a large amount of deionized water until the pH of the top liquid was 7-8 to obtain MXene-N(Na + intercalated MXene materials).

[0078] 3) Suspend 6.3g of sulfanilic acid in 30mL of water and cool in an ice bath. A solution of 9 mL HCl and 30 mL water was precooled and slowly added to the suspension with stirring in an ice bath. After 15 minu...

Embodiment 3

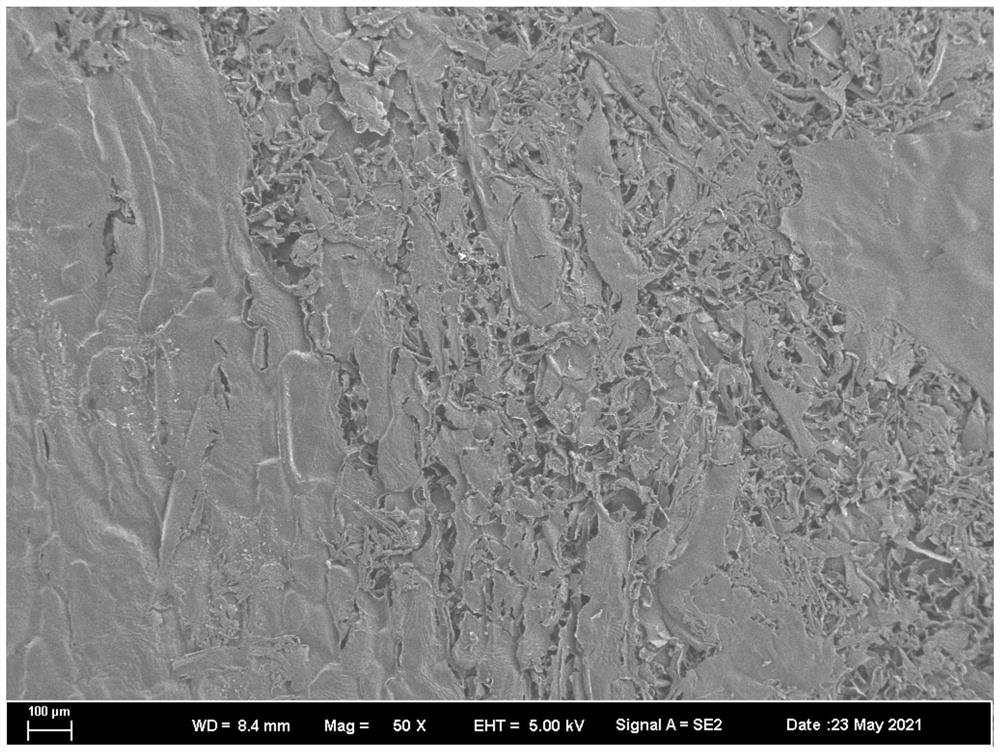

[0081] The preparation of embodiment 3 modified MXene materials

[0082] 1) Add 3g Ti 3 AlC 2 The powder was slowly dipped into a Teflon beaker filled with 40 mL of HF aqueous solution and etched at room temperature for 48 h. The resulting suspension was then transferred to a centrifuge tube and centrifuged. The wet pellet was washed with deionized water and centrifuged several times. Accordion-like two-dimensional MXene material Ti obtained by HF acid selective etching 3 C 2 .

[0083] 2) After decanting the liquid in the previous step, add a small amount of dilute NaOH solution dropwise to the centrifuge tube, transfer the solution to a beaker, and stir for 2 hours. The product was centrifuged and washed several times with a large amount of deionized water until the pH of the top liquid was 7-8 to obtain MXene-N(Na + intercalated MXene materials). Under this structure, Na ions are intercalated between MXene sheets, and the interlayer spacing of MXene will be enlarged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com