Multifunctional polyvinyl alcohol nano composite material and preparation method thereof

A nanocomposite material, polyvinyl alcohol technology, applied in nanotechnology and other directions, can solve the problems of pure polyvinyl alcohol antibacterial and ultraviolet shielding limitations, and achieve the effects of excellent ultraviolet shielding performance, high yield and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

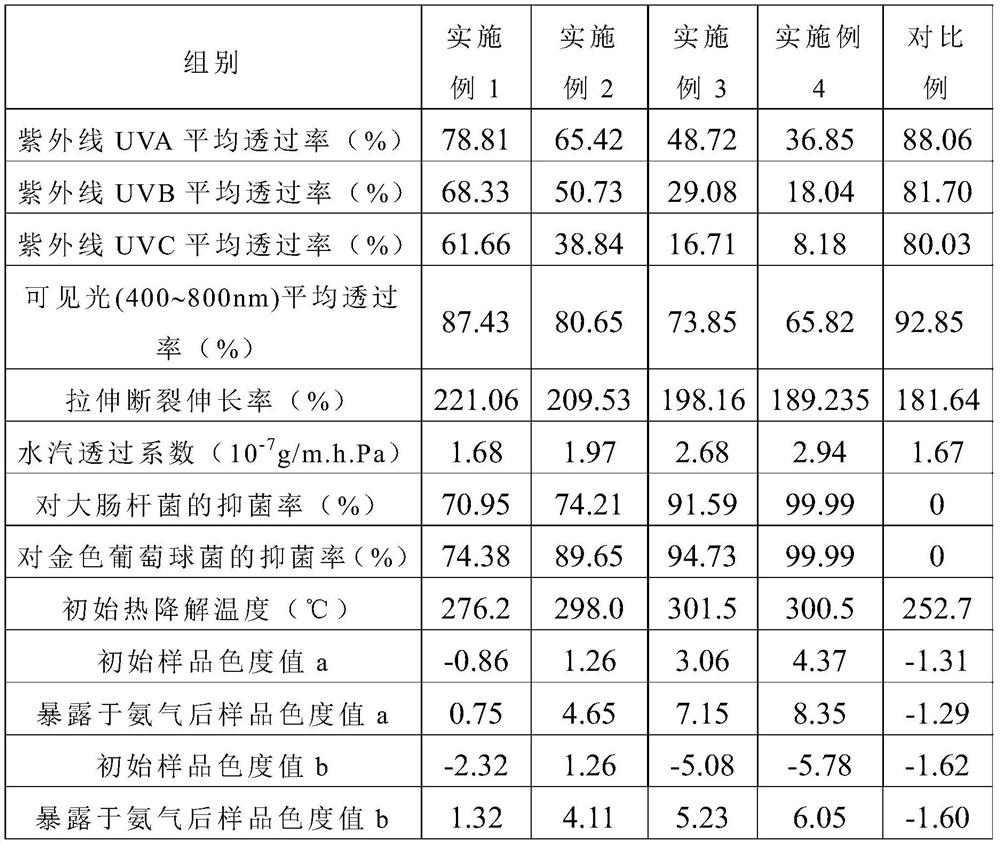

Examples

Embodiment 1

[0018] (1) Preparation of modified cellulose nanocrystals: disperse 4 mass parts of cellulose nanocrystals in 765 mass parts, deionized water-DMF composite solvent with a mass ratio of 100:665, add 6 mass parts cobalt nitrate, after stirring for 30min to mix uniformly, then add 4 parts by mass of aminotrimethylene phosphoric acid, stir for 40min to mix uniformly, then transfer the obtained uniform dispersion to the reactor for solvothermal reaction, the solvothermal reaction temperature is 140°C, reaction time 24h, cooling after solvothermal reaction, centrifugation, washing, and drying to obtain modified cellulose nanocrystals for later use;

[0019] (2) Preparation of film-forming liquid: disperse the modified cellulose nanocrystals of 1 mass part in 3000 mass parts of deionized water, add 100 mass parts of polyvinyl alcohol to the dispersion, heat to 85 ° C, stir Mix evenly for 2 hours, then cool down to room temperature, remove air bubbles with ultrasound, and obtain a uni...

Embodiment 2

[0022] (1) Preparation of modified cellulose nanocrystals: disperse 4 mass parts of cellulose nanocrystals in 765 mass parts, deionized water-DMF composite solvent with a mass ratio of 100:665, add 6 mass parts cobalt nitrate, after stirring for 30min to mix uniformly, then add 4 parts by mass of aminotrimethylene phosphoric acid, stir for 40min to mix uniformly, then transfer the obtained uniform dispersion to the reactor for solvothermal reaction, the solvothermal reaction temperature is 140°C, reaction time 24h, cooling after solvothermal reaction, centrifugation, washing, and drying to obtain modified cellulose nanocrystals for later use;

[0023] (2) Preparation of film-forming liquid: disperse 3 mass parts of modified cellulose nanocrystals in 3000 mass parts of deionized water, add 100 mass parts of polyvinyl alcohol to the dispersion, heat to 85 ° C, stir Mix evenly for 2 hours, then cool down to room temperature, remove air bubbles with ultrasound, and obtain a unifor...

Embodiment 3

[0026] (1) Preparation of modified cellulose nanocrystals: disperse 4 mass parts of cellulose nanocrystals in 765 mass parts, deionized water-DMF composite solvent with a mass ratio of 100:665, add 6 mass parts cobalt nitrate, after stirring for 30min to mix uniformly, then add 4 parts by mass of aminotrimethylene phosphoric acid, stir for 40min to mix uniformly, then transfer the obtained uniform dispersion to the reactor for solvothermal reaction, the solvothermal reaction temperature is 140°C, reaction time 24h, cooling after solvothermal reaction, centrifugation, washing, and drying to obtain modified cellulose nanocrystals for later use;

[0027] (2) Preparation of film-forming liquid: disperse the modified cellulose nanocrystals of 5 parts by mass in deionized water of 3000 parts by mass, add 100 parts by mass of polyvinyl alcohol to the dispersion, heat to 85 ° C, stir Mix evenly for 2 hours, then cool down to room temperature, remove air bubbles with ultrasound, and ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com