Nickel/molybdenum selenide difunctional composite catalyst and preparation method and application thereof

A technology of composite catalysts and selenides, applied in electrolytic components, electrolytic inorganic material coatings, electrolytic processes, etc., can solve the problems of difficult control of material morphology and influence on material specific surface area, and achieve optimal adsorption and desorption free energy, high Effect of OER performance, large electrochemical active surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A preparation method of a nickel / molybdenum selenide bifunctional composite catalyst, specifically comprising the steps of:

[0044] (1) Cleaning of foamed nickel: Use dilute hydrochloric acid with a concentration of 6mol / L to ultrasonically wash the foamed nickel at room temperature in an ultrasonic machine for 15 minutes, then use deionized water and absolute ethanol to ultrasonically wash the foam at room temperature in an ultrasonic machine in sequence Nickel for 10 minutes, in which the length and width of nickel foam are fixed at 1 cm, and finally dried in vacuum at 65°C for 20 minutes;

[0045] (2) Preparation of electrolyte: 1mmol selenium dioxide, 2.5mmol nickel acetate and 5mmol sodium molybdate were dissolved in 50mL deionized water to prepare electrolyte, which was designed to be saturated in the presence of a small amount of solid reagent precipitation;

[0046] (3) The process of electrodeposition: in the standard three-electrode system, with graphite rod ...

Embodiment 2

[0049] The difference between this embodiment and embodiment 1 is that sodium molybdate is not added, and other parameters and specific implementation steps are the same as in embodiment 1.

Embodiment 3

[0051] The difference between this embodiment and embodiment 1 is that nickel acetate is not added, and other parameters and specific implementation steps are the same as embodiment 1.

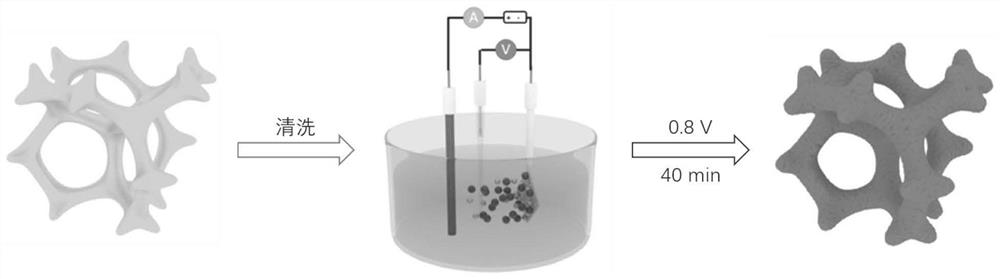

[0052] figure 1 For the preparation of Ni 3 Se 2 / MoSe 2 process flow chart.

[0053] The above steps 1 to 3 can be prepared to obtain Ni 3 Se 2 / MoSe 2 . As a comparison, step 2 does not add sodium molybdate, Ni can be obtained 3 Se 2 ; And step 2 does not add nickel acetate, MoSe can be obtained 2 .

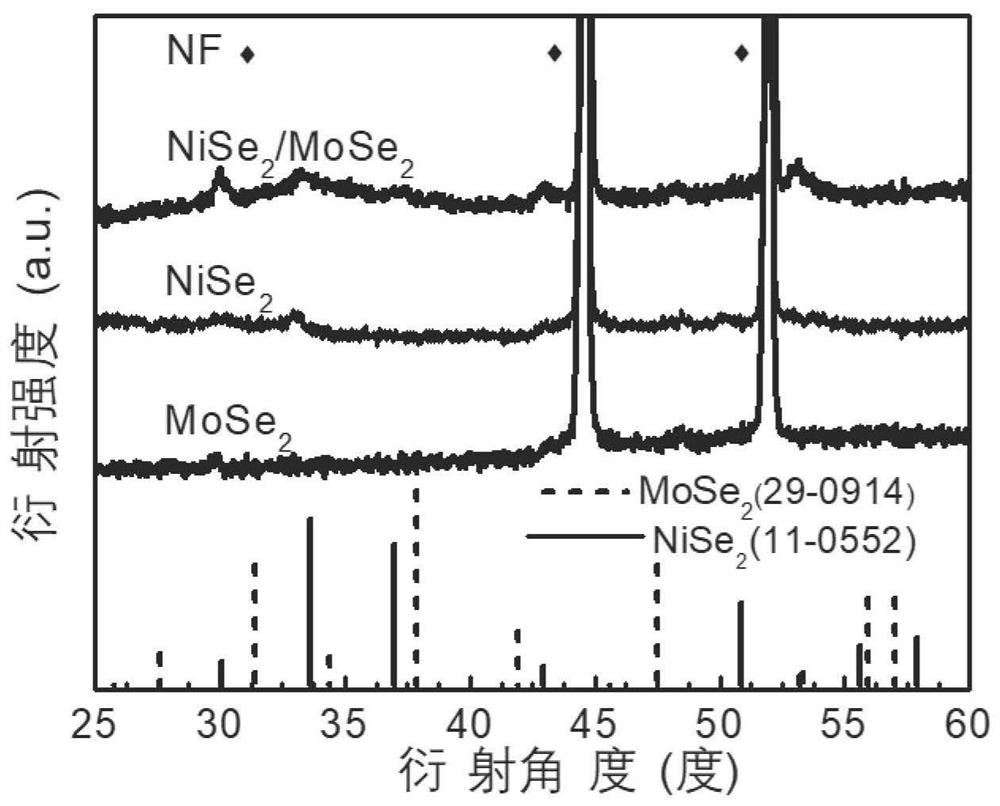

[0054] figure 2 For the Ni prepared in embodiment 1, embodiment 2, embodiment 3 3 Se 2 / MoSe 2 、Ni 3 Se 2 、MoSe 2 The XRD figure of, can find out from the figure that the Ni prepared by the present invention 3 Se 2 / MoSe 2 、Ni 3 Se 2 They are all pure phases, and the two relatively large peaks belong to the peaks of the base nickel foam. On the other hand, it may be due to Ni 3 Se 2 / MoSe 2 Medium MoSe 2 The content is low or its crystallinity is poor, in Ni 3 Se 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com