Synthesis method of iohexol

A synthetic method, iohexol technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as limited production capacity, increased cost, and reduced yield, so as to reduce equipment requirements and increase production capacity , The effect of reducing material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

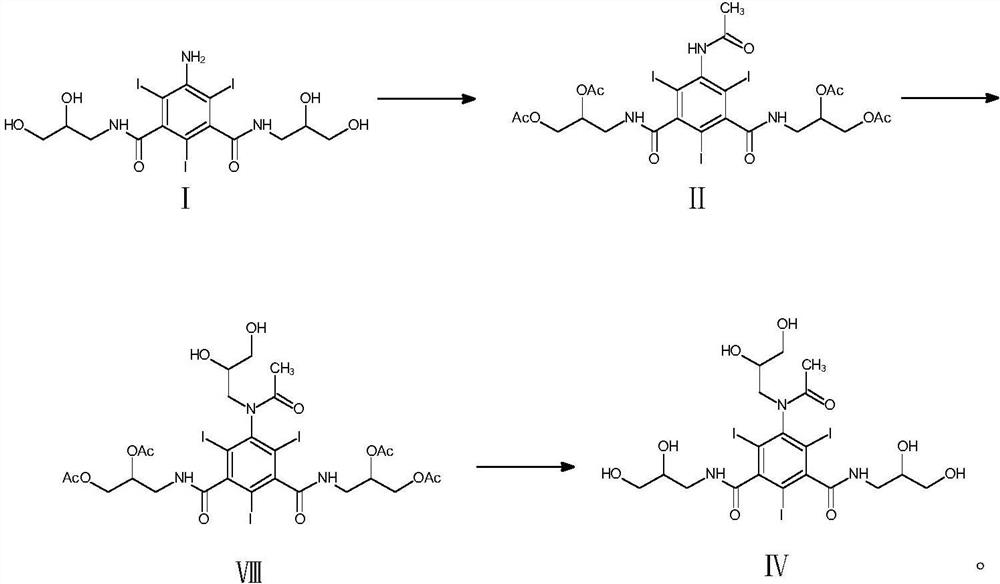

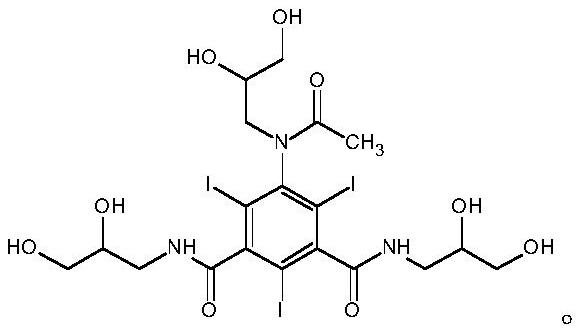

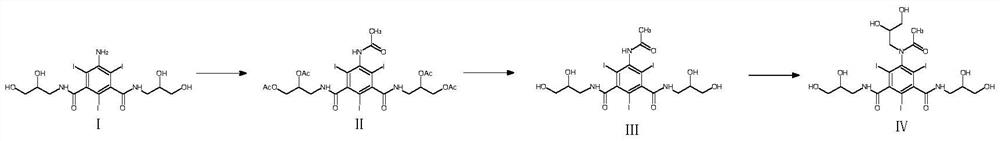

Method used

Image

Examples

Embodiment 1

[0034] Synthesis of Compound (Ⅱ), N,N'-bis(2,3-diacetoxypropyl)-5-acetamido-2,4,6-triiodoisophthalamide

[0035] In a 500ml reaction flask, put 70.5g (0.1mol) of compound (I), add 150ml of acetic acid as a solvent, add 61.2g (0.6mol) of acetic anhydride, add 0.1g (0.001mol) of concentrated sulfuric acid (98%) ), stir and heat up to 60-65 °C for 12 hours, control the temperature not to exceed 65 °C, evaporate to dryness under reduced pressure until no obvious fractions are distilled to obtain 92g of oil, add 210ml of dichloromethane to dissolve the oil, add 100ml Water, after stirring at room temperature for 30min, extract and stratify, add 100ml of 5% sodium bicarbonate aqueous solution to the organic layer, stir at room temperature for 30min, extract and stratify, and extract the organic layer twice with 100ml of deionized water again, organic layer. The layer was dehydrated by adding anhydrous magnesium sulfate for later use.

[0036] Compound (VIII), 5-[acetyl(2,3-dihydrox...

Embodiment 2

[0041] Synthesis of Compound (Ⅱ), N,N'-bis(2,3-diacetoxypropyl)-5-acetamido-2,4,6-triiodoisophthalamide

[0042] In a 500ml reaction flask, add 70.5g (0.1mol) of compound (I), add 150ml of chloroform as a solvent, add 50g of DMAC (N,N-dimethylacetamide) as an acid binding agent, heat up To 60°C, add 55g (0.7mol) of acetyl chloride dropwise with stirring. The rate of addition is controlled so that the temperature in the reaction flask does not exceed 65°C. The dropwise addition is completed in about 3 hours. Heating at 65°C, distill under reduced pressure until no obvious fractions are distilled out, evaporate the solvent to obtain an oily substance, add 210ml of chloroform to dissolve, cool down to 5°C, add 100ml of water, stir below 10°C for 30min, extract layers , the organic layer was eluted with 100 ml of an aqueous sodium bicarbonate solution with a mass concentration of 5% until the aqueous layer was neutral (about 2 times), washed and extracted twice with 100 ml of deio...

Embodiment 3

[0048] Compound (VIII), 5-[acetyl(2,3-dihydroxypropyl)amino]-N,N'-bis(2,3-diacetoxypropyl)-2,4,6-tri Synthesis of iodo-1,3-benzenedicarboxamide

[0049] The dehydrated organic layer in Example 1 was transferred to a 500ml reaction flask, and after dichloromethane was evaporated, 210ml of tetrahydrofuran was added to dissolve, 18.5g (0.25mol) of glycidol was added, and 1.2g of tetramethylguanidine was added as a catalyst. , the temperature was raised to 40°C, the reaction was stirred for 16h, sampled for TLC point plate detection, after the reaction reached the point of no starting material, acetic acid was added to adjust the pH to neutrality to quench the reaction, and the tetrahydrofuran was evaporated to dryness under reduced pressure to obtain 113.7g of an oily substance. TLC developing solvent ethyl acetate:n-hexane=5:1.

[0050] The synthesis of compound (IV) crude iohexol:

[0051] The oily substance of the previous step was dissolved in 210ml of ethanol, 2g of concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com