Preparation method of PtCu alloy catalyst for efficient electrocatalytic synthesis of ammonia

An alloy catalyst and electrocatalysis technology, applied in the direction of electrodes, electrolysis components, electrolysis process, etc., can solve the problems of enhanced activity of synthetic ammonia and poor conductivity, and achieve the effect of promoting activation and dissociation, high specific surface area, and enhanced adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the PtCu alloy catalyst for efficient electrocatalytic synthesis of ammonia according to the present invention comprises the following steps:

[0034] 1) Preparation of WS by intercalation exfoliation method2 Nanosheets;

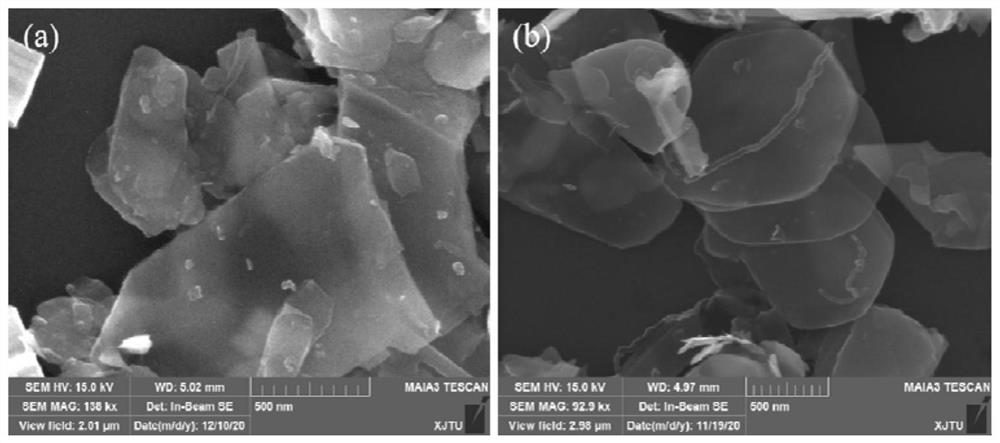

[0035] 2) WS prepared by step 1) 2 Preparation of WO from nanosheets 3 Nanosheets;

[0036] 3) by NaBH 4 Cooperative reduction of metal precursors to anchor PtCu alloy nanoparticles on WO 3 On nanosheets, PtCu alloy catalysts for efficient electrocatalytic synthesis of ammonia.

[0037] The concrete operation of step 1) is:

[0038] The block WS 2 Mix it with potassium sodium tartrate hydrate and grind it evenly, then put it into the reaction kettle and react at 150-250°C for 8-15h. During the reaction, the metal ion K + and Na + Insert block WS 2 The interlayer, while making the WS through the tartaric acid chain 2 The block expands, the reaction product is naturally cooled to room temperature, and then the reactio...

Embodiment 1

[0046] The preparation method of the PtCu alloy catalyst for efficient electrocatalytic synthesis of ammonia according to the present invention comprises the following steps:

[0047] 1) Preparation of WS by intercalation exfoliation method 2 Nanosheets;

[0048] The block WS 2 Mix it with potassium sodium tartrate hydrate and grind it evenly, then put it into the reaction kettle and react at 250°C for 10 hours. During the reaction, the metal ion K + and Na + Insert block WS 2 The interlayer, while making the WS through the tartaric acid chain 2 The block expands, the reaction product is naturally cooled to room temperature, and then the reaction product is placed in H 2 Ultrasonic crushing in O for 4 hours, wherein the power of the ultrasonic crushing instrument was 800kW to obtain the mixture, the mixture was centrifuged at 4000rpm, washed with ethanol and water, and then freeze-dried to obtain WS 2 nanosheets, where the bulk WS 2 The mass ratio to potassium sodium ta...

Embodiment 2

[0058] The preparation method of the PtCu alloy catalyst for efficient electrocatalytic synthesis of ammonia according to the present invention comprises the following steps:

[0059] 1) Preparation of WS by intercalation exfoliation method 2 Nanosheets;

[0060] The block WS 2 Mix it with potassium sodium tartrate hydrate and grind it evenly, then put it into the reaction kettle and react at 200°C for 10 hours. During the reaction, the metal ion K + and Na + Insert block WS 2 The interlayer, while making the WS through the tartaric acid chain 2 The block expands, the reaction product is naturally cooled to room temperature, and then the reaction product is placed in H 2 Ultrasonic crushing in O for 6 hours, wherein the power of the ultrasonic crushing instrument was 800kW to obtain the mixture, the mixture was centrifuged at 4000rpm, washed with ethanol and water, and then freeze-dried to obtain WS 2 nanosheets, where the bulk WS 2 The mass ratio to potassium sodium ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com