Perfluorosulfonic acid/coupled phosphotungstic acid lignin coating liquid, ion exchange membrane and preparation method thereof

An ion-exchange membrane and perfluorosulfonic acid technology, which is applied in the field of perfluorosulfonic acid/coupled phosphotungstic acid lignin coating liquid, can solve the problem of increasing the overall size and weight, easy dehydration of PFSA membrane, and decreased proton conductivity. Problems, achieve the effect of improving stability and life, low price, and improving water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

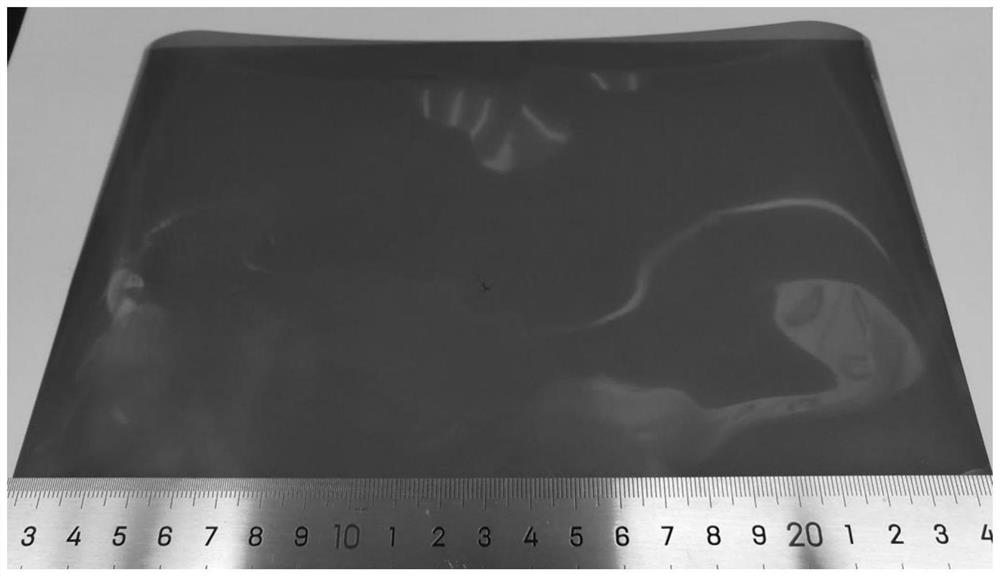

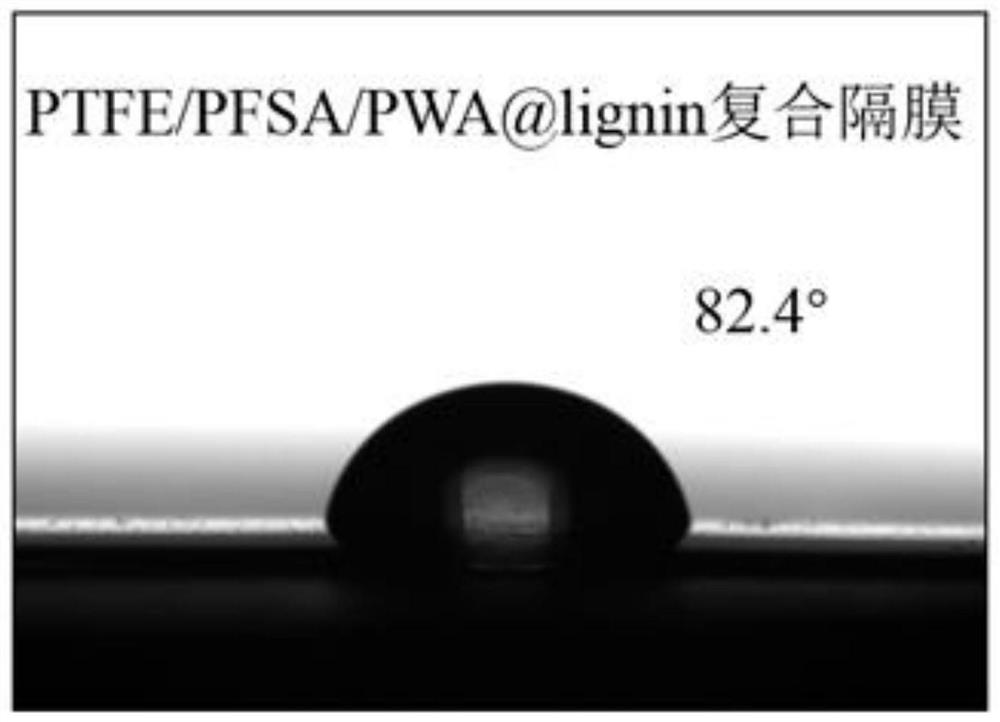

[0057] Embodiment 1 provides a preparation method of polytetrafluoroethylene / perfluorosulfonic acid / coupled phosphotungstic acid lignin ion exchange membrane, the specific steps are as follows:

[0058] Preparation of coupling agent modified lignin: adding lignin and 3-aminopropyltriethoxysilane with a mass ratio of 1:1 to a mixed solution of deionized water and ethanol with a volume ratio of 1:9 (wood The mass volume ratio of the element and the coupling agent in the mixed solution of deionized water and ethanol is 1 / 50g / mL), reacted at 30°C and 1000r / min stirring speed for 12h, after the reaction, washed with deionized water The reaction product was repeatedly centrifuged and washed, put in an oven at 60°C, and dried for 24 hours to obtain coupling agent-modified lignin; preparation of coupling phosphotungstic acid lignin: add the above-mentioned coupling agent-modified lignin to 10wt% phosphorus In tungstic acid aqueous solution (the ratio of the mass of coupling agent-modi...

Embodiment 2

[0068] Example 2, a preparation method of polytetrafluoroethylene / perfluorosulfonic acid / coupled phosphotungstic acid lignin ion exchange membrane, the only difference from Example 1 is: coupling phosphotungstic acid lignin and perfluorosulfonic acid The mass ratio of resin is 1:100.

[0069] The polytetrafluoroethylene / perfluorosulfonic acid / coupled phosphotungstic acid lignin ion exchange membrane prepared in Example 2 has a thickness of 11 μm, which is too thin to easily cause fuel permeation, which is worse than the membrane prepared in Example 1, which is not conducive to the battery long run. Compared with the ion exchange membrane prepared in Example 1, the ion exchange membrane prepared in Example 2 is not conducive to the commercial application of proton exchange membrane fuel cells. The ion-exchange membrane prepared in Example 2 has a uniform and dense texture, no porous polytetrafluoroethylene film, no dissolution phenomenon of coupled phosphotungstic acid lignin,...

Embodiment 3

[0071] Example 3, a preparation method of polytetrafluoroethylene / perfluorosulfonic acid / coupled phosphotungstic acid lignin ion exchange membrane, the only difference from Example 1 is: coupling phosphotungstic acid lignin and perfluorosulfonic acid The mass ratio of resin is 1:10.

[0072] The polytetrafluoroethylene / perfluorosulfonic acid / coupled phosphotungstic acid lignin ion-exchange membrane prepared in Example 3 has a thickness of 23 μm, and the ion-exchange membrane prepared in Example 3 has a uniform texture, but it is different from that prepared in Example 1. Compared with the ion-exchange membrane, the ion-exchange membrane prepared in Example 3 has the phenomenon of coupled phosphotungstic acid lignin agglomeration, and is not suitable for application in proton exchange fuel cells.

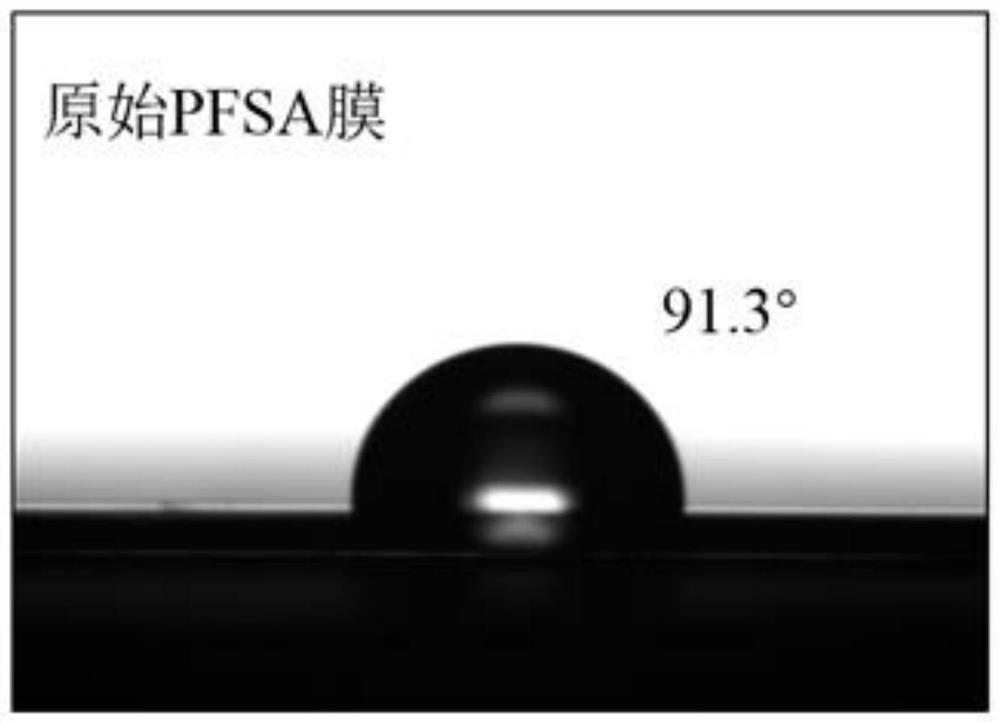

[0073] Water absorption, tensile strength and proton conductivity were tested on the polytetrafluoroethylene / perfluorosulfonic acid / coupled phosphotungstic acid lignin ion exchange m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com