Heat insulation and heat preservation coating coating and preparation method thereof

A thermal insulation and coating technology, which is applied in the direction of anti-corrosion coatings, fire-proof coatings, coatings, etc., can solve the problems of poor adhesion between thermal insulation coatings and coke oven bodies, and achieve low thermal conductivity, strong adhesion, and construction easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Another object of the present invention is to provide a kind of preparation method of thermal insulation paint as above, and this preparation method comprises the steps:

[0045] S1: preparing an organosilicon modification solution;

[0046] S2: preparing nano hollow microbeads;

[0047] S3: preparing fumed silica gel;

[0048] S4: According to parts by weight, add 25 to 35 parts of nano-hollow microbeads to 15 to 20 parts of the organosilicon modification solution, and mix evenly to obtain solution A;

[0049] S5: In terms of parts by weight, add 10 to 20 parts of nano silicate inorganic binder, 10 to 15 parts of fumed silica gel, 5 to 15 parts of inorganic hollow fiber powder, 2 -8 parts of nano-rare earth oxide, 1-5 parts of additives, and 0.5 parts of water are uniformly mixed to obtain a thermal insulation coating.

[0050] For the thermal insulation coating provided by this application, firstly, the prepared nano hollow microspheres are fully mixed with the org...

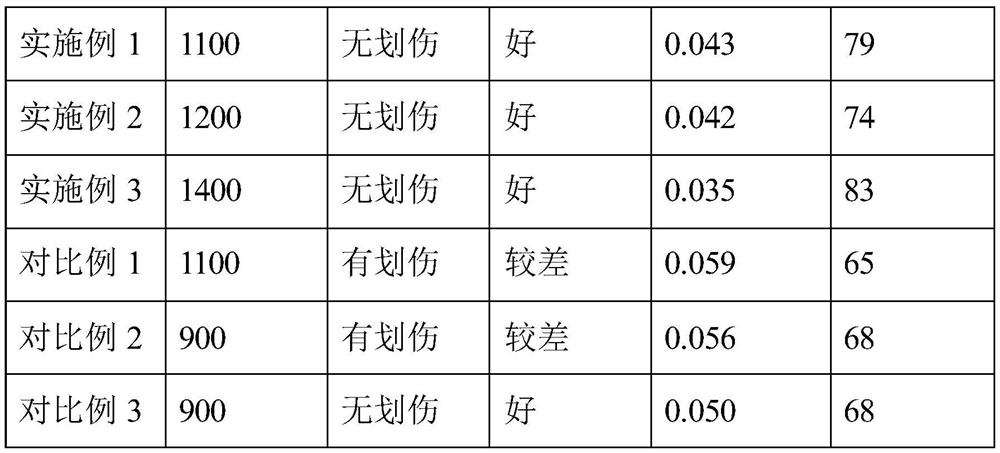

Embodiment 1

[0067] This embodiment provides a method for preparing a thermal insulation coating, comprising the following steps:

[0068] S1: In parts by weight, 1.5 parts of methyl monomer and 1 part of tetrafluoroethylene monomer were polymerized at 85°C to obtain a silicone modified solution;

[0069] S21: According to parts by weight, 1 part of BN-1000 stabilizer is mixed with 5 parts of ethanol to obtain solution B;

[0070] S22: According to parts by weight, 15 parts of nano-ceramic hollow microspheres are added to solution B, and mixed uniformly to obtain solution C;

[0071] S23: According to parts by weight, add 1 part of neodymium nitrate and 5 parts of nickel nitrate to solution C, heat to 30 ° C, and mix uniformly to obtain a dispersed liquid;

[0072] S24: After filtering, cleaning and drying the dispersed liquid in sequence, sintering at 600°C for 5 hours to obtain nano hollow microspheres; the nano hollow microspheres are nano hollow microspheres coated with neodymium nitr...

Embodiment 2

[0081] This embodiment provides a method for preparing a thermal insulation coating, comprising the following steps:

[0082] S1: In parts by weight, 1.5 parts of methyl monomer and 1 part of tetrafluoroethylene monomer were polymerized at 85°C to obtain a silicone modified solution;

[0083] S21: According to parts by weight, 5 parts of BN-1000 stabilizer and 1 part of ethanol are mixed to obtain solution B;

[0084] S22: According to parts by weight, 25 parts of nano-ceramic hollow microspheres are added to solution B, and mixed uniformly to obtain solution C;

[0085] S23: According to parts by weight, add 5 parts of neodymium nitrate and 1 part of nickel nitrate to the solution C, heat to 35 ° C, and mix uniformly to obtain a dispersed liquid;

[0086] S24: After filtering, cleaning and drying the dispersed liquid in sequence, sintering at 900°C for 3 hours to obtain nano hollow microspheres; the nano hollow microspheres are nano hollow microspheres coated with neodymium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com