Preparation method and application of alcohol-dispelling oligomeric pectin

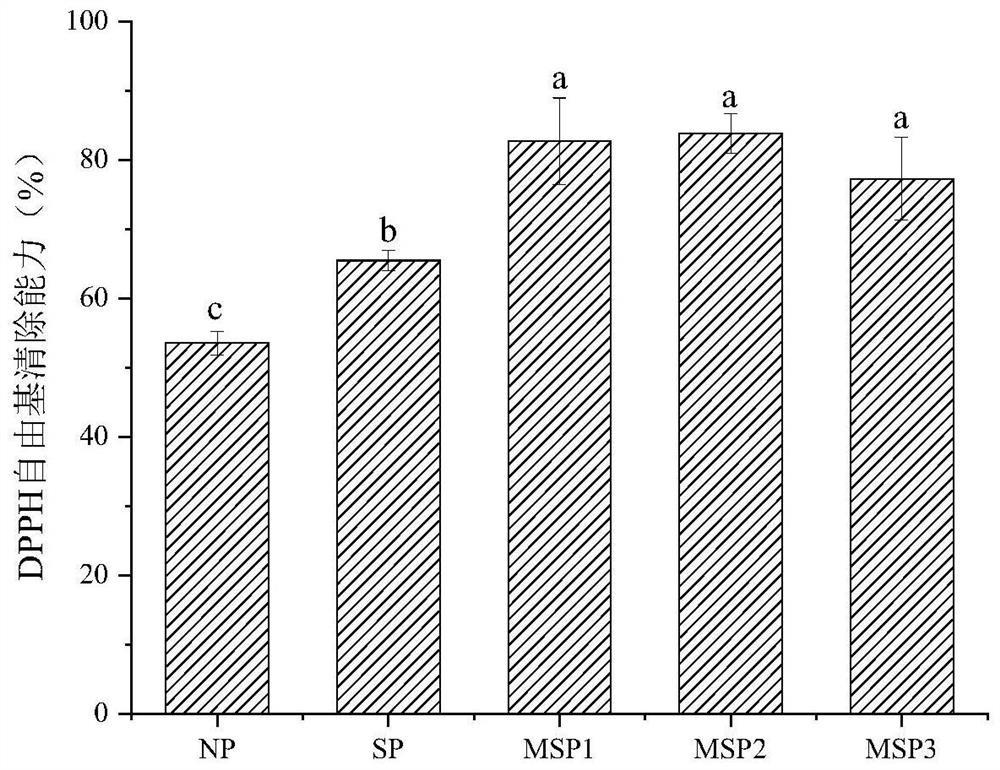

A technology for oligomeric pectin and hangover relief, which is applied in the directions of antidote, fermentation, drug combination, etc., can solve problems such as low grafting efficiency of products, and achieve the effects of improving comprehensive utilization rate, remarkable antioxidant capacity and good use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

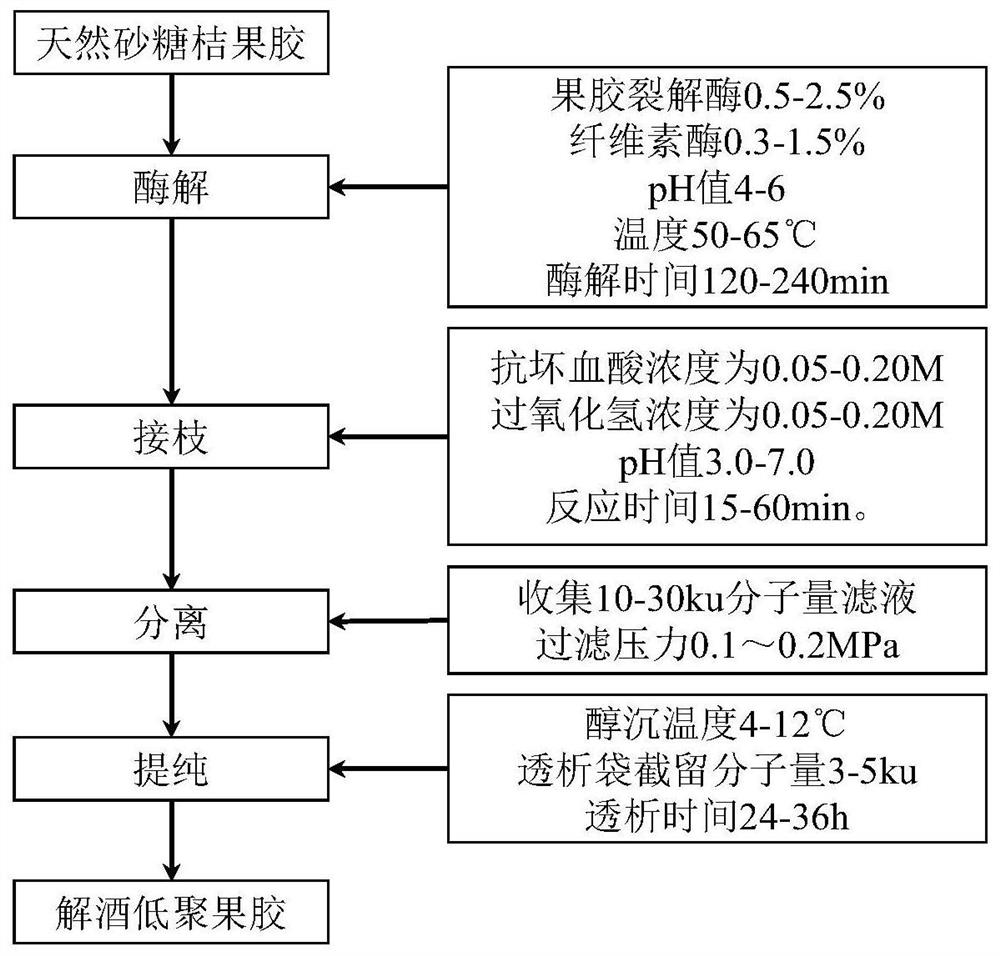

Method used

Image

Examples

Embodiment 1

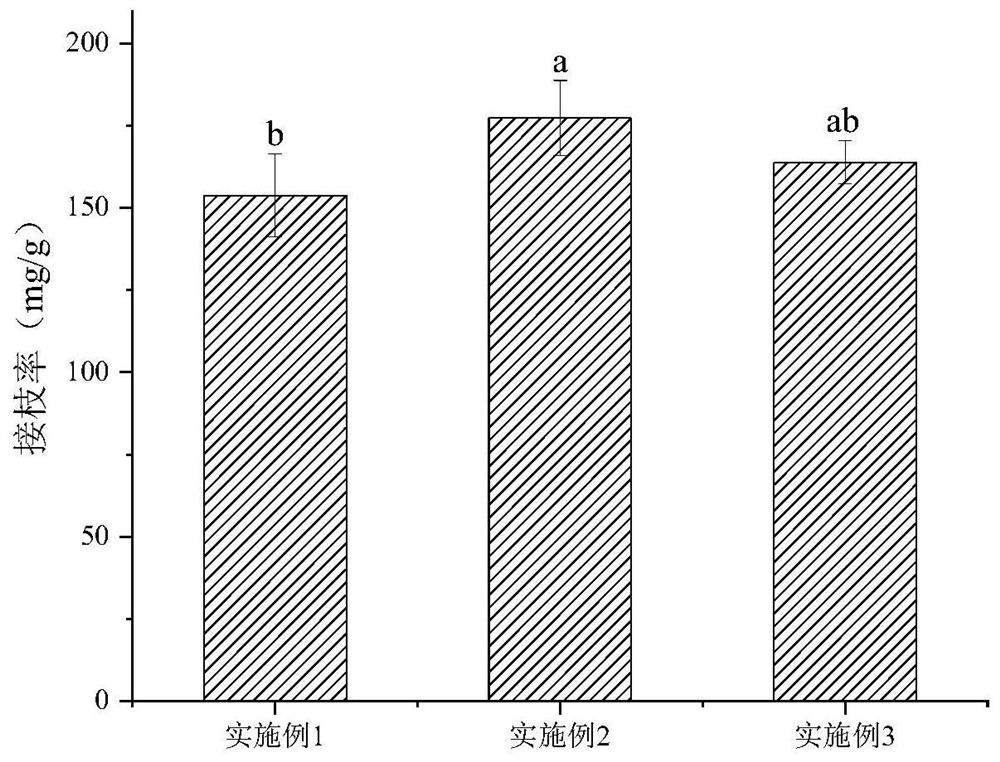

[0028] Take 100g of natural sugar orange peel pectin in an Erlenmeyer flask, add 2.4L of distilled water, use citric acid to adjust the pH to 4.5, add pectin lyase to 1.5% of dry weight, and add cellulase to 0.8% of dry weight %, enzymatic hydrolysis for 80 min at 55°C; 2 o 2 To a concentration of 0.18M, adjust the pH value to 5.0, then add 80g of quercetin, stir and react for 30min; the reaction solution is treated with a cellulose membrane with a molecular weight cut-off of 30ku and 10ku, and the filtrate with a molecular weight of 10-30ku is collected, and the filtration pressure is set to 0.12MPa; The filtrate was cooled to 6°C, precipitated with ethanol, and the precipitate was dialyzed for 28 hours using a dialysis bag with a molecular weight cut-off of 3ku, and dried to obtain oligomerized modified pectin.

Embodiment 2

[0030] Take 100g of natural sugar orange peel pectin in an Erlenmeyer flask, add 2.4L of distilled water, use citric acid to adjust the pH to 4.8, add pectin lyase to 0.5% of dry weight, and add cellulase to 1.0% of dry weight %, enzymatic hydrolysis for 100 min at 58°C; after enzymatic hydrolysis, add ascorbic acid to the enzymatic hydrolysis solution to a concentration of 2 o 2 To a concentration of 0.16M, adjust the pH value to 5.5, then add 80g of quercetin, stir and react for 45min; the reaction solution is treated with a cellulose membrane with a molecular weight cut-off of 30ku and 10ku, and the filtrate with a molecular weight of 10-30ku is collected, and the filtration pressure is set to 0.12MPa; The filtrate was cooled to 6°C, precipitated with ethanol, and the precipitate was dialyzed for 28 hours using a dialysis bag with a molecular weight cut-off of 3ku, and dried to obtain oligomerized modified pectin.

Embodiment 3

[0032] Take 100g of natural sugar orange peel pectin in an Erlenmeyer flask, add 2.4L of distilled water, use citric acid to adjust the pH to 5.0, add pectin lyase to 1.2% of dry weight, and add cellulase to 0.8% of dry weight , enzymatic hydrolysis at 60°C for 90 minutes; after the enzymatic hydrolysis, add ascorbic acid to the enzymatic hydrolysis solution to a concentration of 0.12M, H 2 o 2 To a concentration of 0.12M, adjust the pH value to 4.5, then add 80g of quercetin, stir and react for 45min; the reaction solution is treated with a cellulose membrane with a molecular weight cut-off of 30ku and 10ku, and the filtrate with a molecular weight of 10-30ku is collected, and the filtration pressure is set to 0.12MPa; The filtrate was cooled to 6°C, precipitated with ethanol, and the precipitate was dialyzed for 28 hours using a dialysis bag with a molecular weight cut-off of 3ku, and dried to obtain oligomerized modified pectin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grafting rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com