A kind of preparation method of thermosensitive hydrogel and thermosensitive hydrogel

A temperature-sensitive hydrogel and temperature-sensitive technology, applied in the field of biomedical materials, can solve problems such as single function and lack of promoting effect on wound repair, and achieve the effect of promoting accelerated healing, promoting wound repair, and removing active oxygen to promote wound repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

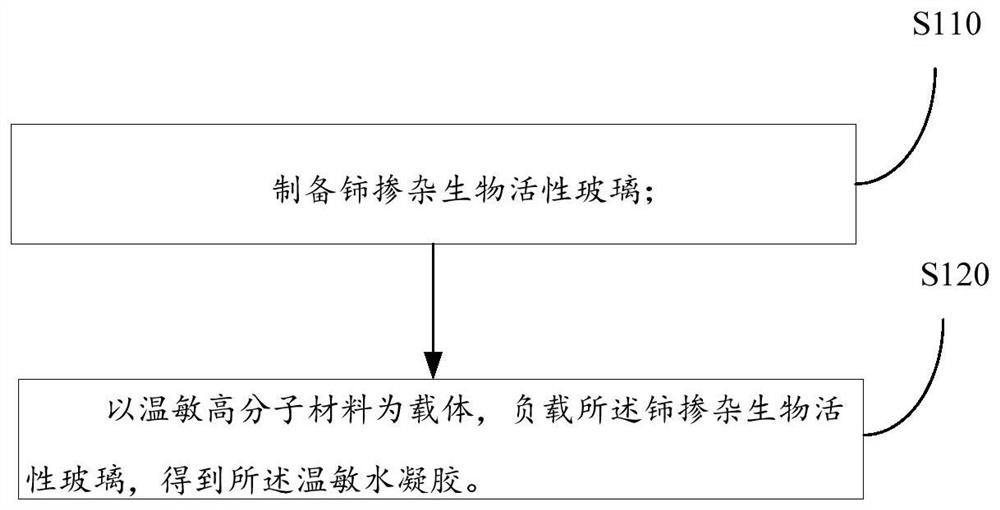

[0038] see figure 1 , is a flow chart of the steps of the method 100 for preparing a thermosensitive hydrogel provided in an embodiment of the present application, including the following steps:

[0039] Step S110: preparing cerium-doped bioactive glass.

[0040] In some of these embodiments, the step of preparing cerium-doped bioactive glass specifically includes the following steps:

[0041] Step S111: adding ammonia water to the solvent to keep the solvent alkaline.

[0042] Specifically, the solvent is a mixed solution of absolute ethanol and water.

[0043] Further, a catalyst is added to the solvent, and the catalyst is cetyltrimethylammonium bromide.

[0044] Specifically, the added amount of the ammonia water is kept equal to the added amount of the silicon source.

[0045] It can be understood that the pH is adjusted by ammonia water to promote the hydrolysis of the silicon source, and the adjustable range is the volume ratio of ammonia water: tetraethyl orthosili...

Embodiment 1

[0065] 1. Preparation of cerium-doped bioactive glass:

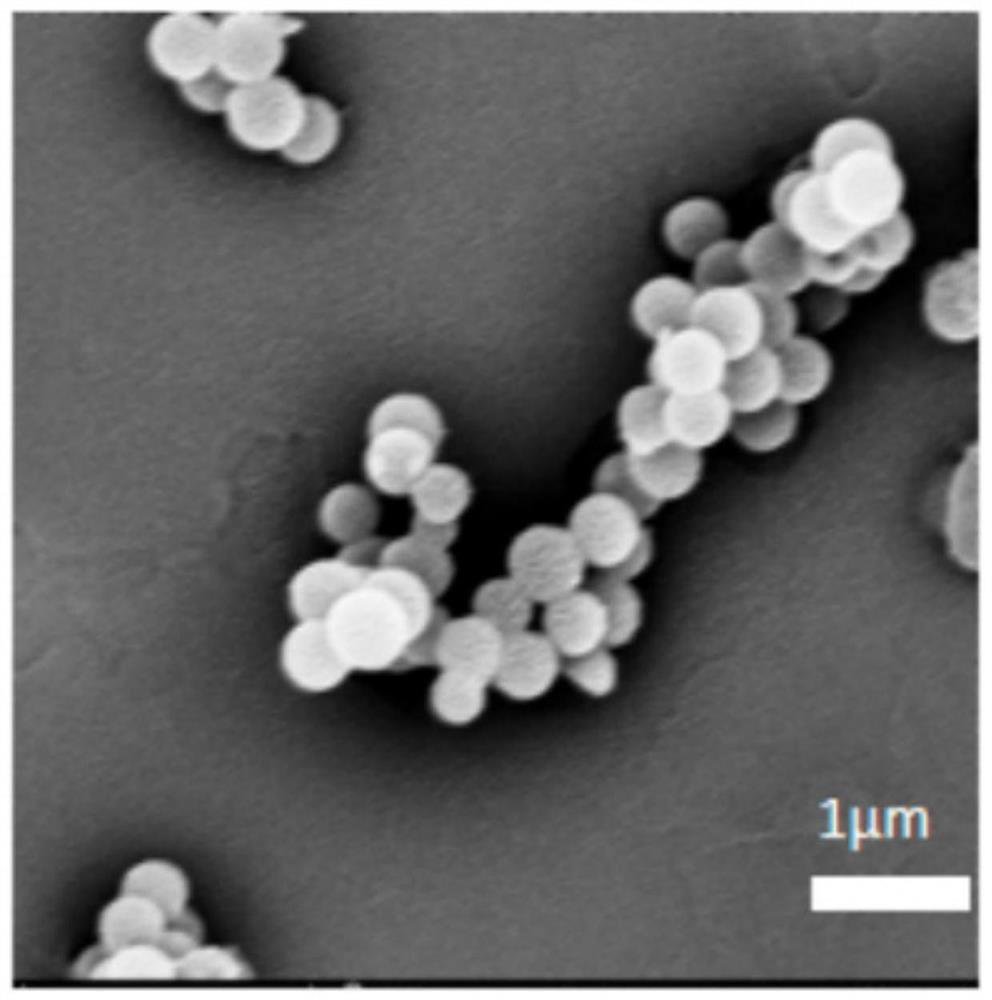

[0066] With the volume ratio of 20ml:40ml dehydrated alcohol / water mixed solution as solvent, add 0.12g cetyltrimethylammonium bromide, 0.75ml ammoniacal liquor, make described solvent keep alkaline, stir until completely dissolving; Then Add 0.75ml tetraethyl orthosilicate and 0.055ml triethyl phosphate dropwise, finally add 0.10g cerium nitrate hexahydrate, 0.12g calcium nitrate tetrahydrate, stir magnetically at 35°C for 3h, and a light brown precipitate (nano grade biological glass sol); collect the white precipitate, wash it alternately with absolute ethanol and deionized water for 3 times, and then vacuum-dry to obtain a white lump; finally, transfer the white precipitate to a crucible for high-temperature calcination (heating rate: 1°C / min, Maintenance temperature: 650° C., maintenance time: 3 h) After high temperature treatment, naturally cool to obtain a powdery white powder, which is nano-scale cerium-doped bio...

Embodiment 2

[0073] 1. Preparation of cerium-doped bioactive glass:

[0074] With the volume ratio of 20ml:40ml dehydrated alcohol / water mixed solution as solvent, add 0.12g cetyltrimethylammonium bromide, 0.75ml ammoniacal liquor, make described solvent keep alkaline, stir until completely dissolving; Then Add 0.75ml tetraethyl orthosilicate and 0.055ml triethyl phosphate dropwise, finally add 0.10g cerium nitrate hexahydrate, 0.12g calcium nitrate tetrahydrate, stir magnetically at 37°C for 3h, and a light brown precipitate (nano Grade biological glass sol); collect the white precipitate, alternately wash twice with absolute ethanol and deionized water, and then vacuum-dry to obtain a white lump; finally, transfer the white precipitate to a crucible for high-temperature calcination (heating rate: 0.5°C / min, Maintenance temperature: 700° C., maintenance time: 2.5 h) After high temperature treatment, naturally cool to obtain a powdery white powder, which is nano-scale cerium-doped bioactiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com