Superhydrophilic-superoleophobic particle for oily sewage treatment as well as preparation method and application thereof

A hydrophilic, oleophobic and super-hydrophilic technology, applied in separation methods, chemical instruments and methods, grease/oily substances/floating matter removal devices, etc. Low problems, to achieve stable super-hydrophilic and super-oleophobic, efficient treatment, high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A preparation method for superhydrophilic-superoleophobic particles for oily sewage treatment, comprising the following steps:

[0044] (1) Granular core material pretreatment: the granular core material is sieved, washed and dried for later use;

[0045] (2) Preparation of superhydrophilic-superoleophobic dispersion: dissolve perfluorocarboxylic acid in a solvent, then add film-forming aids, then add alkali, and complete the reaction to obtain superhydrophilic-superoleophobic dispersion; The molar ratio of the carboxyl group in the fluorocarboxylic acid to the hydroxyl group in the base is (1-2):1; the solvent includes ethanol or acetone, and the base includes sodium hydroxide, iron hydroxide or calcium hydroxide.

[0046] (3) Add the superhydrophilic-superoleophobic dispersion liquid into the dried particle core material, add micron-sized particle material and nano-sized particle material in turn, stir until completely dispersed, and then dry to obtain the super Hydr...

Embodiment 1

[0052] Dissolve 0.98g of perfluorononanoic acid in 20mL of acetone, add 0.04g of NaOH solid, stir until completely dissolved, then add 0.05g of propylene glycol, and stir magnetically at 1000r / min for 5min to obtain a superhydrophilic-superoleophobic dispersion liquid.

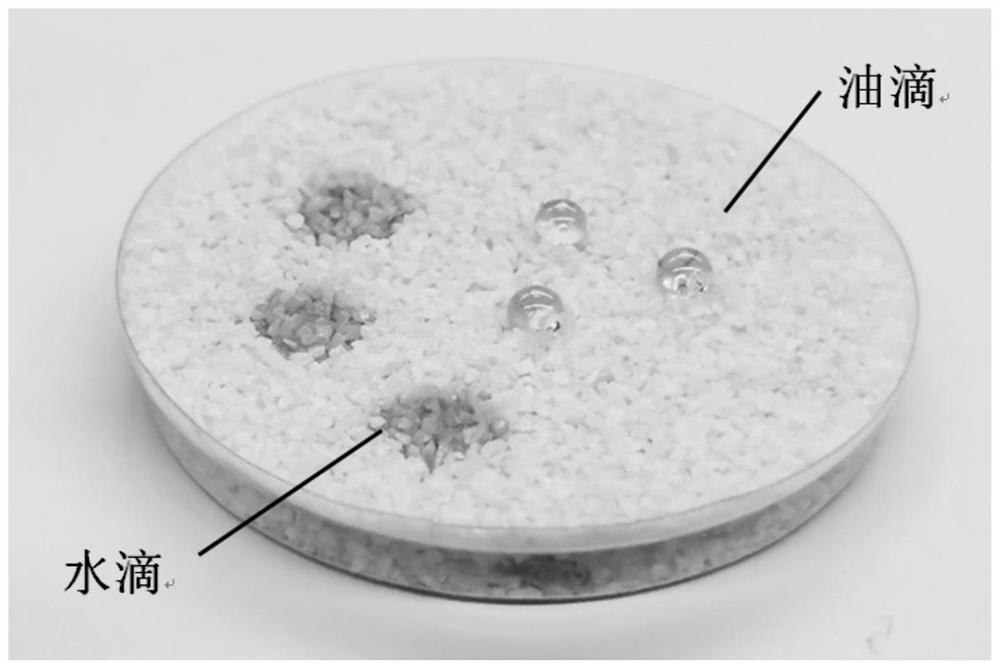

[0053] Take 200g of stainless steel sieved, cleaned and dried quartz sand and pour it into a stirring pot, then pour the superhydrophilic-superoleophobic dispersion into the quartz sand, stir, and at the same time add 3g of silicon with a particle size of 5-50μm Ash and 1.5g of SiO with a particle size of 10-50nm 2 , Stir for 5 minutes until completely dispersed. Put the stirred sample into a vacuum drying oven, and dry it at 55°C for 24 hours to obtain a superhydrophilic-superoleophobic quartz sand filter material.

Embodiment 2

[0055] Dissolve 0.92g of perfluorooctanoic acid in 20mL of absolute ethanol, and add 0.049g of Cu(OH) 2 , stirred until completely dissolved, then added 0.02g of polyvinylpyrrolidone, and stirred magnetically at 1000r / min for 5min to obtain a superhydrophilic-superoleophobic dispersion. Take 150g of stainless steel sieved, cleaned and dried river sand and pour it into a mixing pot, then pour the superhydrophilic-superoleophobic dispersion into the river sand, stir, and at the same time add 3g of powder with a particle size of 5-50μm Coal ash and 1.2g of TiO with a particle size of 10-50nm 2 , Stir for 5 minutes until completely dispersed. Put the stirred sample into a vacuum drying oven, and dry it at 55°C for 24 hours to obtain a superhydrophilic-superoleophobic river sand filter material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com