High-flowability flame-retardant nylon slice for thin-wall glass fabric composite material as well as preparation method and application of high-flowability flame-retardant nylon slice

A composite material and flame-retardant nylon technology, which is applied in the field of high-flow flame-retardant nylon chips for thin-wall glass fiber cloth composite materials and their preparation, which can solve the problem of low flame-retardant efficiency, decreased mechanical properties of finished products, easy moisture absorption, etc. problem, to achieve the effect of good flame retardancy, good dispersion and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] A preparation method for nylon slices, the method comprising the steps of:

[0060] (1) Mix inorganic hypophosphite, synergistic flame retardant, antioxidant, dispersant, compatibilizer and flow modifier in a high mixer for 2-5 minutes;

[0061] (2) Mix the obtained mixture with nylon 6 slices in a high mixer for 5-15 minutes;

[0062] (3) Put the obtained mixture into a twin-screw extruder, melt blending and extruding and granulate, wherein, when melt blending and extruding, the temperature of the melting section is set as: feeding port 220°C, conveying section 250°C ℃, meshing section 240-245℃, exhaust section 210℃, machine head 235℃, feeding speed 15-35r / min, host speed 250-400 r / min, cutting speed 1500-3500r / min.

[0063] The application of nylon slices, the nylon slices are used to prepare thin-walled glass fiber cloth composite materials, the specific method is: after the nylon slices are dried, the nylon slices are pressed with the glass fiber cloth by a tableti...

Embodiment 1

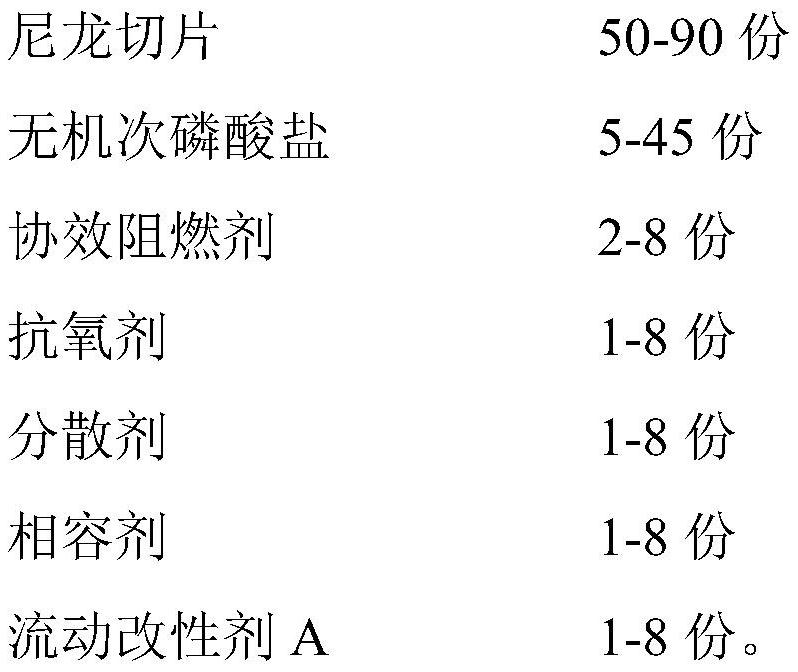

[0066] A high-flow flame-retardant nylon chip used for glass fiber cloth composite materials, by weight, includes the following components:

[0067]

[0068] A kind of preparation method for the high-flow flame-retardant nylon slice that is used for glass fiber cloth composite material comprises the steps:

[0069] Step 1: Mix the above-mentioned inorganic hypophosphite, synergistic flame retardant, antioxidant, dispersant, compatibilizer, and flow modifier A in a high-speed mixer for 2-5 minutes.

[0070] Step 2, the mixture obtained in the above step 1 is mixed with nylon in a high mixer, and the mixing time is 5-15min.

[0071] Step 3, the mixture obtained in the above step 2 is melt blended and extruded by a twin-screw extruder and pelletized.

[0072] The preparation method of the above-mentioned halogen-free flame-retardant masterbatch, wherein, the temperature of the melting section during the melt blending and extrusion of the step 3 is set as the feeding port-220°...

Embodiment 2

[0074] A high-flow flame-retardant nylon chip used for glass fiber cloth composite materials, by weight, includes the following components:

[0075]

[0076] The preparation method of high-flow flame-retardant nylon chip, step is the same as embodiment 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com