Perovskite CsPbX3 nanocrystal as well as preparation method and application thereof

A nanocrystal and titanium ore technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of precursor purity, demanding storage conditions, poor reproducibility of nanocrystal synthesis, and achieve easy process control, Improve luminous efficiency and reduce the effect of halogen vacancies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

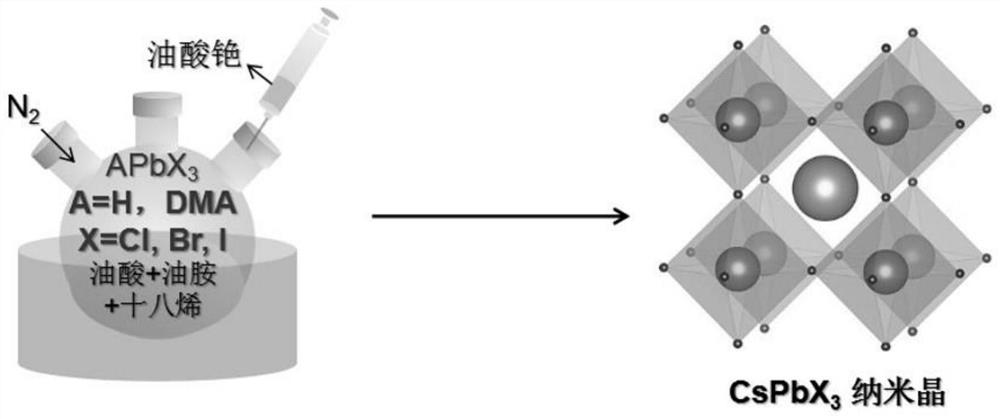

Method used

Image

Examples

Embodiment 1

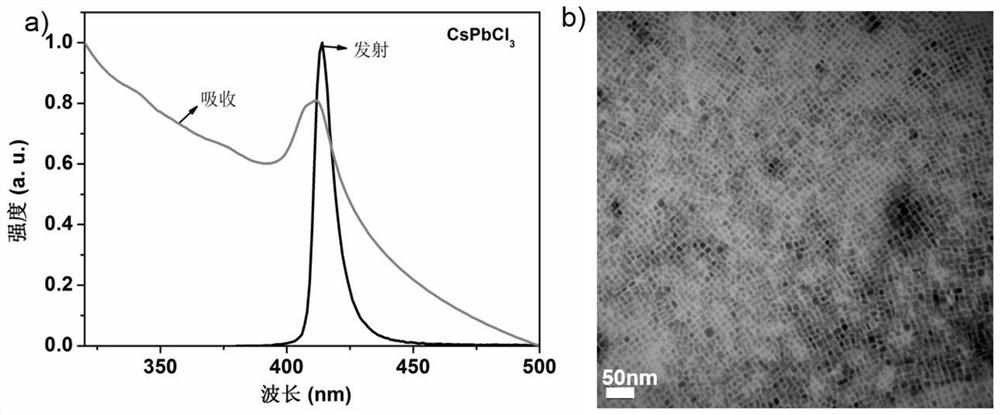

[0054] Example 1: CsPbCl 3 Preparation of nanocrystals

[0055] Step 1. Take 5.0g of lead particles and 5mL of concentrated hydrochloric acid into a 25mL three-necked flask, heat the mixture to 80°C for 6h at 1000rpm, and cool to room temperature naturally to obtain a white precipitate. The white precipitate was washed 5 times with ether. Finally, dry under vacuum overnight at 60 °C to obtain HPbCl 3 .

[0056] Step 2. Add 0.814g of cesium carbonate, 20mL of octadecene and 2.5mL of oleic acid into a 50mL three-necked flask. Under a nitrogen atmosphere, heat the mixture to 110°C and keep the temperature for 60min to complete the cesium carbonate Dissolved, then naturally cooled to room temperature to form a precursor solution of cesium oleate.

[0057] Step 3, weigh 0.118g of HPbCl obtained in step 1 3 The powder was added to a three-necked flask containing 1 mL of oleic acid, 1 mL of oleylamine and 10 mL of octadecene, and stirred at 130 °C for 35 min under a nitrogen atm...

Embodiment 2

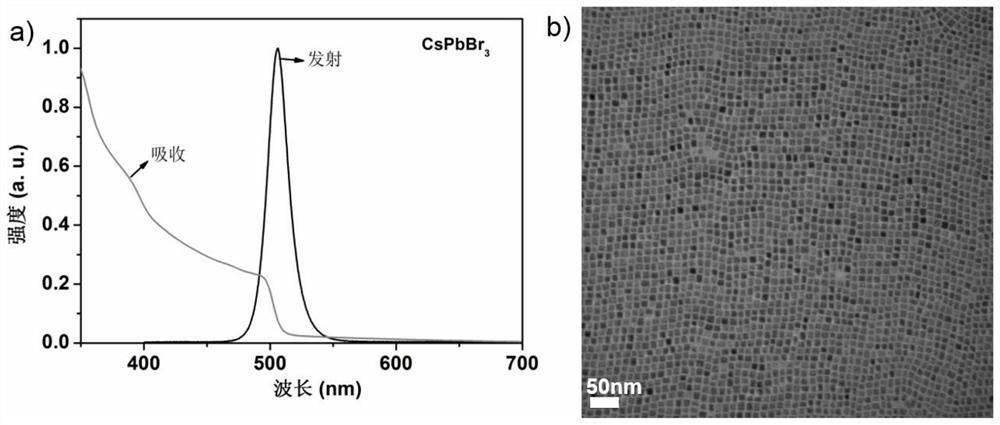

[0060] Example 2: CsPbBr 3 Preparation of nanocrystals

[0061] Step 1, take 5g PbBr respectively 2 , 5mL, 48wt% HBr aqueous solution and 10mL dimethylformamide were placed in a 25mL three-necked flask, and at 1000rpm, the mixture was heated to 80°C and kept at this temperature to react overnight, adding 5mL of absolute ethanol for precipitation, and then Cooling to room temperature gave a white precipitate. The white precipitate was washed 5 times with ether. Finally, vacuum drying at 60 °C overnight to obtain APbBr 3 Powder (A=H or DMA).

[0062] Step 2. Add 0.814g of cesium carbonate, 20mL of octadecene and 2.5mL of oleic acid into a 50mL three-necked flask. Under a nitrogen atmosphere, heat the mixture to 110°C and keep the temperature for 60min to complete the cesium carbonate Dissolved, then naturally cooled to room temperature to form a precursor solution of cesium oleate.

[0063] Step 3, weigh 0.168g APbBr obtained in step 1 3 The powder was added to a three-ne...

Embodiment 3

[0066] Example 3: CsPbBr 1.5 I 1.5 Preparation of nanocrystals

[0067] Step 1, a) take 5g PbBr 2 , 5mL, 48wt% HBr aqueous solution and 10mL dimethylformamide were placed in a 25mL three-necked flask, and at 1000rpm, the mixture was heated to 80°C and kept at this temperature to react overnight, adding 5mL of absolute ethanol for precipitation, and then Cooling to room temperature gave a white precipitate. The white precipitate was washed 5 times with ether. Finally, vacuum-dried at 60 °C overnight to obtain APbBr 3 (A=H or DMA). b) Take 5g PbI 2 , 5mL, 57wt% HI aqueous solution and 10mL dimethylformamide were placed in a 25mL three-necked flask, and at 1000rpm, the mixture was heated to 80°C and kept at this temperature for overnight reaction, and 5mL of absolute ethanol was added for precipitation, then naturally Cooling to room temperature gave a yellow precipitate. The yellow precipitate was washed 5 times with ether. Finally, dry in vacuum at 60 °C overnight to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com