Electrolyte and aluminum air battery

An aluminum-air battery and electrolyte technology, applied in the field of electrochemistry, can solve problems such as non-compliance with environmental protection requirements, high production costs, and human poisoning, and achieve excellent electrochemical performance, low self-corrosion rate, and prolong discharge life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

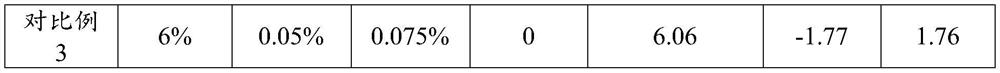

Examples

Embodiment 1

[0044]The electrolyte solution of this embodiment is composed of the following preparation raw materials in mass percentage: 6% sodium chloride, 0.5% corrosion inhibitor and the balance is water. 100g

[0045] The corrosion inhibitor of the present embodiment is made up of the preparation raw materials of following mass fraction: 10% natural amino acid (cysteine), 15% saccharide compound (glucose), 60% plant essential oil (tea tree essential oil, CAS number : 68647-73-4) and the balance is ethanol.

[0046] The preparation method of the electrolytic solution is as follows: adding sodium chloride to water to obtain a sodium chloride solution; then adding a corrosion inhibitor to the sodium chloride solution to obtain the above electrolytic solution.

[0047] The aluminum-air battery of this embodiment includes an aluminum anode, an air cathode, and an electrolyte, and the electrolyte is the above-mentioned electrolyte for the aluminum-air battery.

[0048] The aluminum anode ...

Embodiment 2

[0055] The difference between this embodiment and embodiment 1 is:

[0056] The electrolyte solution of this embodiment is composed of the following preparation raw materials in mass percentage: 6% sodium chloride, 1% corrosion inhibitor and the balance is water.

[0057] The corrosion inhibitor of the present embodiment is made up of the preparation raw materials of following mass fraction: 10% natural amino acid (cystine), 20% carbohydrate compound (maltose), 60% plant essential oil (tea tree essential oil) and balance to ethanol.

[0058] The self-corrosion rate of the aluminum alloy anode of this embodiment in the electrolyte is 2.17 mg / cm 2 h. The open circuit potential is -1.95V (vs. SHE), and the discharge current density of the air battery in the electrolyte is 100mA / cm 2 When testing for 10 hours, the electromotive force is 2.15V, and the surface of the anode alloy is corroded uniformly.

Embodiment 3

[0060] The difference between this embodiment and embodiment 1 is:

[0061] The electrolyte solution of this embodiment is composed of the following preparation raw materials in mass fraction: 9% sodium chloride, 1% corrosion inhibitor and the balance is water.

[0062] The corrosion inhibitor of the present embodiment comprises the preparation raw material of following mass fraction: 5% natural amino acid (cystine), 10% saccharide compound (fructose), 20% plant essential oil (tea tree essential oil) and remainder is ethanol.

[0063] The self-corrosion rate of the aluminum alloy anode of this embodiment in the electrolyte is 3.58 mg / cm 2 h. The open circuit potential is -1.86V (vs. SHE), and the discharge current density of the air battery in the electrolyte is 100mA / cm 2 When testing for 10 hours, the electromotive force is 1.90V, and the surface of the anode alloy is uniformly corroded.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com