Method for treating sweet potato wastewater

A treatment method and wastewater technology, which is applied in food industry wastewater treatment, water/sewage treatment, light water/sewage treatment, etc., can solve the problems of few treatment processes, poor treatment effect, high cost, etc., to achieve Save processing time, high disinfection efficacy, sufficient decomposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

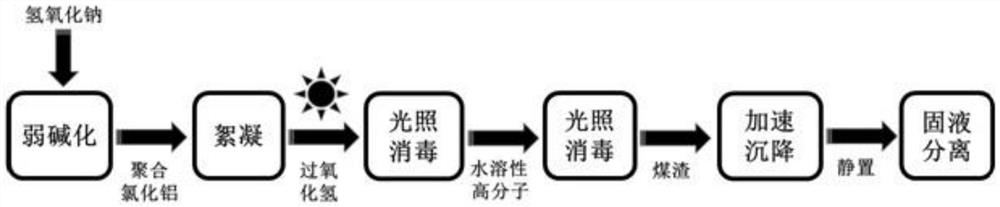

[0032] see figure 1 , a processing method of sweet potato wastewater, it comprises the steps:

[0033] S1: Slowly add sodium hydroxide powder while stirring in the potato wastewater to adjust the pH value of the potato wastewater to 8;

[0034] S2: Slowly add polyaluminum chloride powder with a purity of more than 90% while stirring in the potato wastewater treated in step S1, and continue stirring for 1 hour. The mass ratio of polyaluminum chloride to potato wastewater is 1:10000;

[0035] S3: Slowly add hydrogen peroxide solution with a concentration of 30% to the potato wastewater treated in step S2 while stirring, the mass ratio of hydrogen peroxide to potato wastewater is 1:40000, and then place it in the sun for exposure Or irradiate with an ultraviolet light source with a wavelength less than 380nm and keep stirring for more than 2 hours;

[0036] S4: slowly add cationic polyacrylamide to the potato wastewater treated in step S3 while stirring, and continue stirring f...

Embodiment 2

[0040] see figure 1 , a processing method of sweet potato wastewater, it comprises the steps:

[0041] S1: Slowly add sodium hydroxide powder while stirring in the potato wastewater to adjust the pH value of the potato wastewater to 8;

[0042] S2: Slowly add polyaluminum chloride powder with a purity of more than 90% while stirring in the potato wastewater treated in step S1, and continue stirring for 1 hour. The mass ratio of polyaluminum chloride to potato wastewater is 1:5000;

[0043] S3: Slowly add hydrogen peroxide solution with a concentration of 30% to the potato wastewater treated in step S2 while stirring, the mass ratio of hydrogen peroxide to potato wastewater is 1:40000, and then place it in the sun for exposure Or irradiated by an ultraviolet light source with a wavelength less than 380nm and continuously stirred for more than 2 hours;

[0044] S4: slowly add cationic polyacrylamide to the potato wastewater treated in step S3 while stirring, and continue stirr...

Embodiment 3

[0048] see figure 1 , a processing method of sweet potato wastewater, it comprises the steps:

[0049] S1: Slowly add sodium hydroxide powder while stirring in the potato wastewater to adjust the pH value of the potato wastewater to 9;

[0050] S2: Slowly add polyaluminum chloride powder with a purity of more than 90% while stirring in the potato wastewater treated in step S1, and the mass ratio of polyaluminum chloride to potato wastewater is 1:10000;

[0051] S3: Slowly add hydrogen peroxide solution with a concentration of 30% to the potato wastewater treated in step S2 while stirring, the mass ratio of hydrogen peroxide to potato wastewater is: 1:80000, and then place it under sunlight exposure Or irradiate with an ultraviolet light source with a wavelength less than 380nm, and keep stirring for more than 2 hours;

[0052] S4: Slowly add polyacrylamide and chitosan group (3:1) to the potato wastewater treated in step S3 while stirring, and keep stirring for 3 hours, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com