High-temperature-resistant protective film

A high-temperature resistant protective film and release film technology, which is applied in the direction of pressure-sensitive film/sheet, polymer adhesive additive, film/sheet-shaped adhesive, etc., can solve the problem of large shrinkage rate of pressure-sensitive adhesive layer The range is limited and other issues, to achieve the effect of reduced shrinkage, high stress relaxation rate, and improved high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

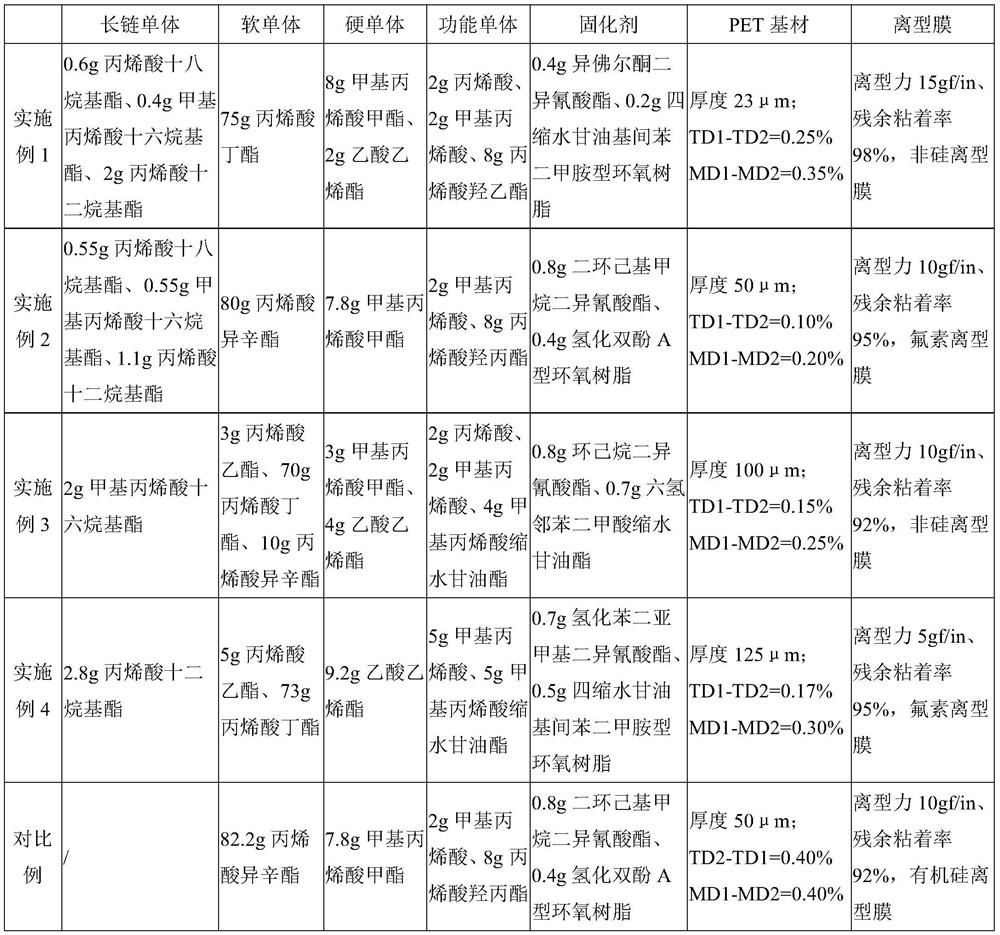

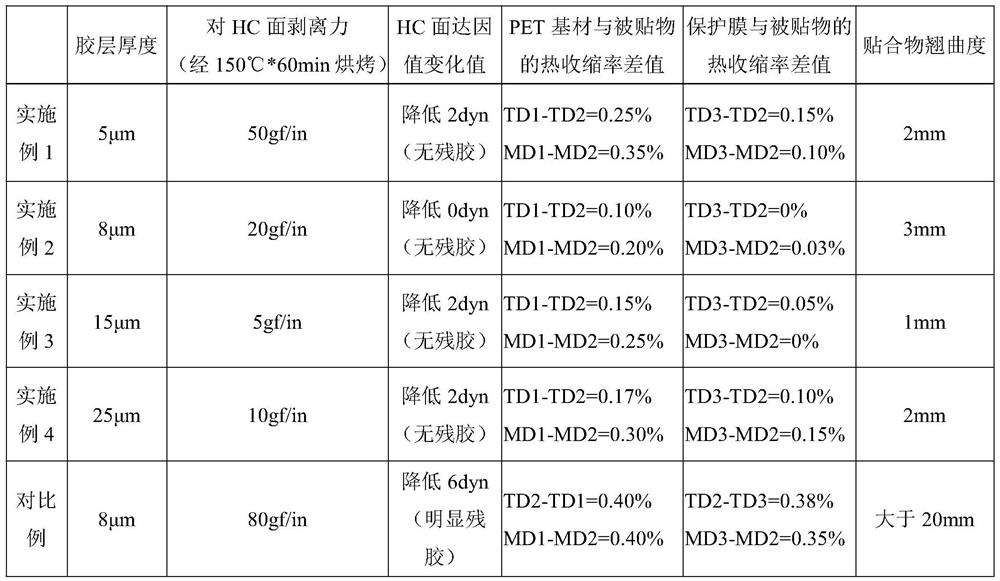

Embodiment 1

[0054] Weigh 0.6g octadecyl acrylate, 0.4g hexadecyl methacrylate, 2g lauryl acrylate, 75g butyl acrylate, 8g methyl methacrylate, 2g vinyl acetate, 2g acrylic acid, 2 g of methacrylic acid and 8 g of hydroxyethyl acrylate were added to the reaction container, and the temperature was raised to 70°C. Evenly add 70g of initiator diluent dropwise, control the dropping time for 3 hours, and then keep warm for 2 hours. Continue to dropwise add 30g of the initiator diluent, control the dropwise addition time for 1 hour, and then keep the temperature for 1 hour. Then the synthesized resin is cooled to room temperature to obtain acrylate resin.

[0055] Weigh 30 g of the above-mentioned acrylate resin, 30 g of ethyl acetate, 0.4 g of isophorone diisocyanate, and 0.2 g of tetraglycidyl m-xylylenediamine epoxy resin, and mix them uniformly to obtain a coating solution. The coating solution is coated on the surface of a 23 μm thick PET substrate. After the PET substrate is subjected to...

Embodiment 2

[0057] Weigh 0.55g octadecyl acrylate, 0.55g hexadecyl methacrylate, 1.1g dodecyl acrylate, 80g isooctyl acrylate, 7.8g methyl methacrylate, 2g methacrylic acid, 8g of hydroxypropyl acrylate was added to the reaction vessel, and the temperature was raised to 70°C. Evenly add 70g of initiator diluent dropwise, control the dropping time for 3 hours, and then keep warm for 2 hours. Continue to dropwise add 30g of the initiator diluent, control the dropwise addition time for 1 hour, and then keep the temperature for 1 hour. Then the synthesized resin is cooled to room temperature to obtain acrylate resin.

[0058] Weigh 30g of the above-mentioned acrylate resin, 30g of ethyl acetate, 0.8g of dicyclohexylmethane diisocyanate, and 0.4g of hydrogenated bisphenol A epoxy resin, and mix them uniformly to obtain a coating solution. The coating solution is coated on the surface of a 50 μm thick PET substrate. After the PET substrate is subjected to high temperature resistance for 60 mi...

Embodiment 3

[0060] Weigh 2g hexadecyl methacrylate, 3g ethyl acrylate, 70g butyl acrylate, 10g isooctyl acrylate, 3g methyl methacrylate, 4g vinyl acetate, 2g acrylic acid, 2g methacrylic acid, 4g formazan Glycidyl acrylate was added to the reaction vessel, and the temperature was raised to 70°C. Evenly add 70g of initiator diluent dropwise, control the dropping time for 3 hours, and then keep warm for 2 hours. Continue to dropwise add 30g of the initiator diluent, control the dropwise addition time for 1 hour, and then keep the temperature for 1 hour. Then the synthesized resin is cooled to room temperature to obtain acrylate resin.

[0061] Weigh 30 g of the above-mentioned acrylate resin, 30 g of ethyl acetate, 0.8 g of cyclohexane diisocyanate, and 0.7 g of glycidyl hexahydrophthalate, and mix them uniformly to obtain a coating solution. The coating solution is coated on the surface of a 100 μm thick PET substrate. After the PET substrate is subjected to high temperature resistance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| warpage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com