Silver-copper-tungsten oxide photochromic composite nano material and preparation method thereof

A composite nanomaterial and photochromic technology, which is applied in the direction of color-changing fluorescent materials, chemical instruments and methods, catalyst activation/preparation, etc., can solve problems such as insufficient potential, low photocatalytic activity, and low conduction band energy level. Achieve excellent visible light absorption, strong photochromic performance, and fast photochromic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

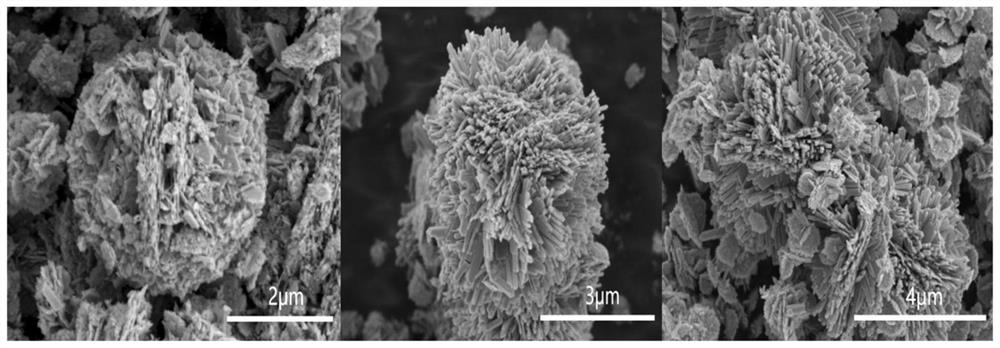

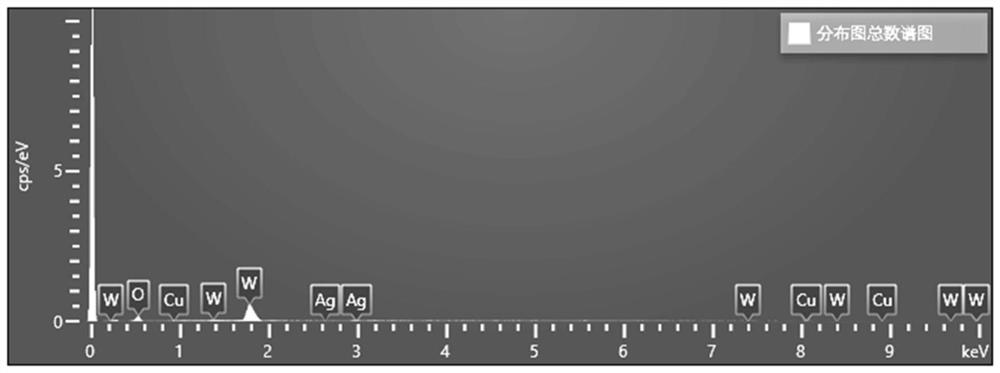

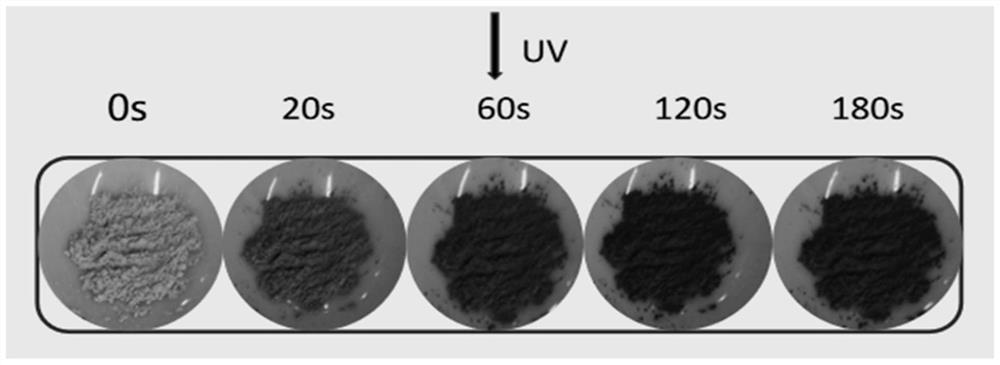

[0036] (1) Preparation of copper-tungsten oxide by hydrothermal reaction: Weigh 0.4948g of sodium tungstate hydrate (Na 2 WO 4 2H 2 (2) and the glycine of 0.0025g are dissolved in the deionized water of 32ml, measure copper nitrate solution (Cu:WO 3 The molar ratio is 1% in turn. Weigh 0.072g of copper nitrate (dissolved in 100ml of deionized water) 5ml, slowly dropwise mix with the above solution respectively, stir evenly to make it completely dissolved. Then, 3ml of 2M hydrochloric acid was added dropwise, and heated in a water bath at 90°C for 30min. Then transfer the above mixed solution to a 50mL polytetrafluoroethylene-lined high-pressure hydrothermal reactor, and react at a high temperature of 150°C for 5h. After the reactor was taken out and cooled to room temperature naturally, the precipitate was collected by centrifugation at a speed of 4000 rpm for 3 minutes, washed alternately with absolute ethanol and deionized water for 3 times, dried at 80°C for 5 hours, an...

Embodiment 2

[0039] (1) Preparation of copper-tungsten oxide by hydrothermal reaction: Weigh 0.4948g of sodium tungstate hydrate (Na 2 WO 4 2H 2 (2) and the glycine of 0.0025g are dissolved in the deionized water of 32ml, measure copper nitrate solution (Cu:WO 3 The molar ratio is 1% in turn. Weigh 0.072g of copper nitrate (dissolved in 100ml of deionized water) 5ml, slowly dropwise mix with the above solution respectively, stir evenly to make it completely dissolved. Then, 3ml of 2M hydrochloric acid was added dropwise, and heated in a water bath at 90°C for 30min. Then transfer the above mixed solution to a 50mL polytetrafluoroethylene-lined high-pressure hydrothermal reactor, and react at a high temperature of 150°C for 5h. After the reactor was taken out and cooled to room temperature naturally, the precipitate was collected by centrifugation at a speed of 4000 rpm for 3 minutes, washed alternately with absolute ethanol and deionized water for 3 times, dried at 80°C for 5 hours, an...

Embodiment 3

[0042] (1) Preparation of copper-tungsten oxide by hydrothermal reaction: Weigh 0.4948g of sodium tungstate hydrate (Na 2 WO 4 2H 2 (2) and the glycine of 0.0025g are dissolved in the deionized water of 32ml, measure copper nitrate solution (Cu:WO 3 The molar ratio is 1% in turn. Weigh 0.072g of copper nitrate (dissolved in 100ml of deionized water) 5ml, slowly dropwise mix with the above solution respectively, stir evenly to make it completely dissolved. Then, 3ml of 2M hydrochloric acid was added dropwise, and heated in a water bath at 90°C for 30min. Then transfer the above mixed solution to a 50mL polytetrafluoroethylene-lined high-pressure hydrothermal reactor, and react at a high temperature of 150°C for 5h. After the reactor was taken out and cooled to room temperature naturally, the precipitate was collected by centrifugation at a speed of 4000 rpm for 3 minutes, washed alternately with absolute ethanol and deionized water for 3 times, dried at 80°C for 5 hours, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com