Method for catalytically oxidizing benzyl alcohol based on phytic acid modified foamed nickel electrode

An electrocatalytic oxidation and nickel foam technology, which is applied in the field of electrocatalysis, can solve the problems of inability to obtain intermediate products, the catalytic efficiency needs to be improved, and the reaction time is long, and achieves the effects of high electrode conversion rate, simple method and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

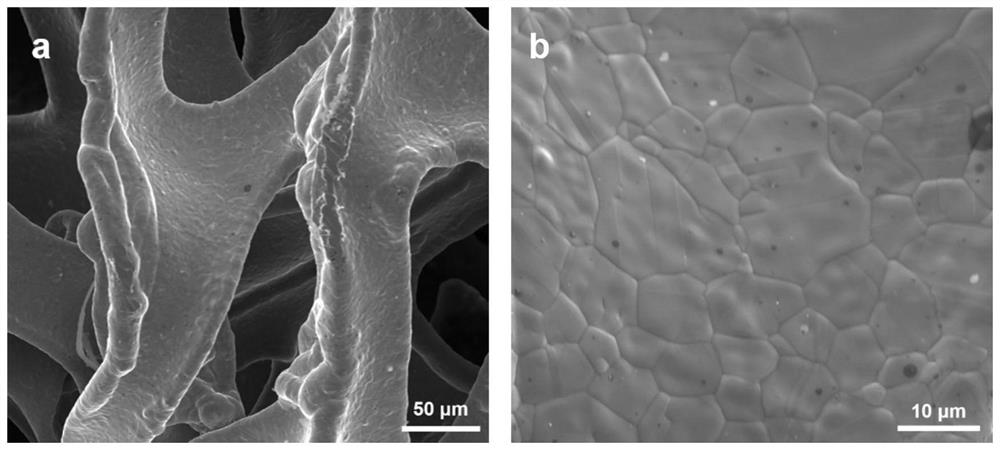

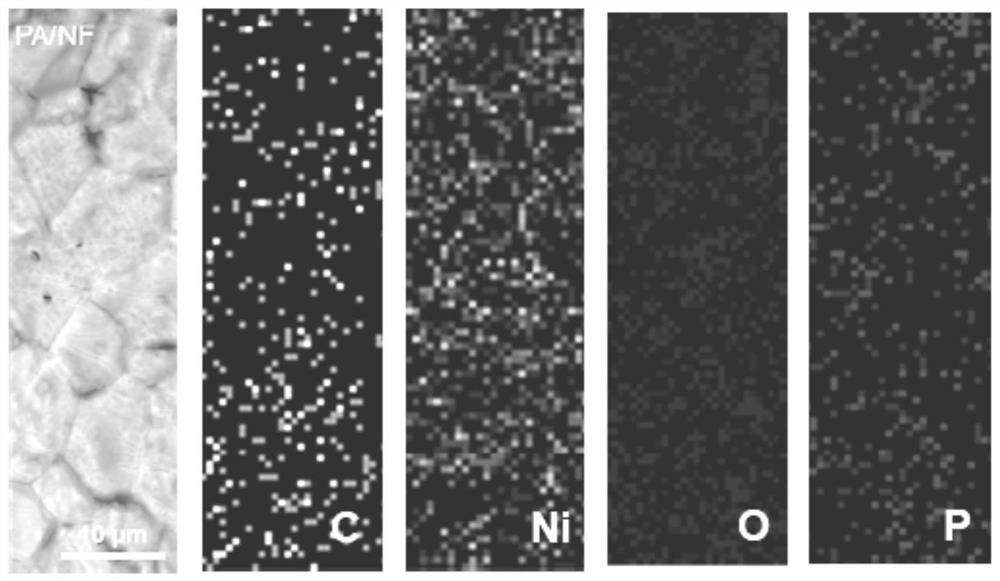

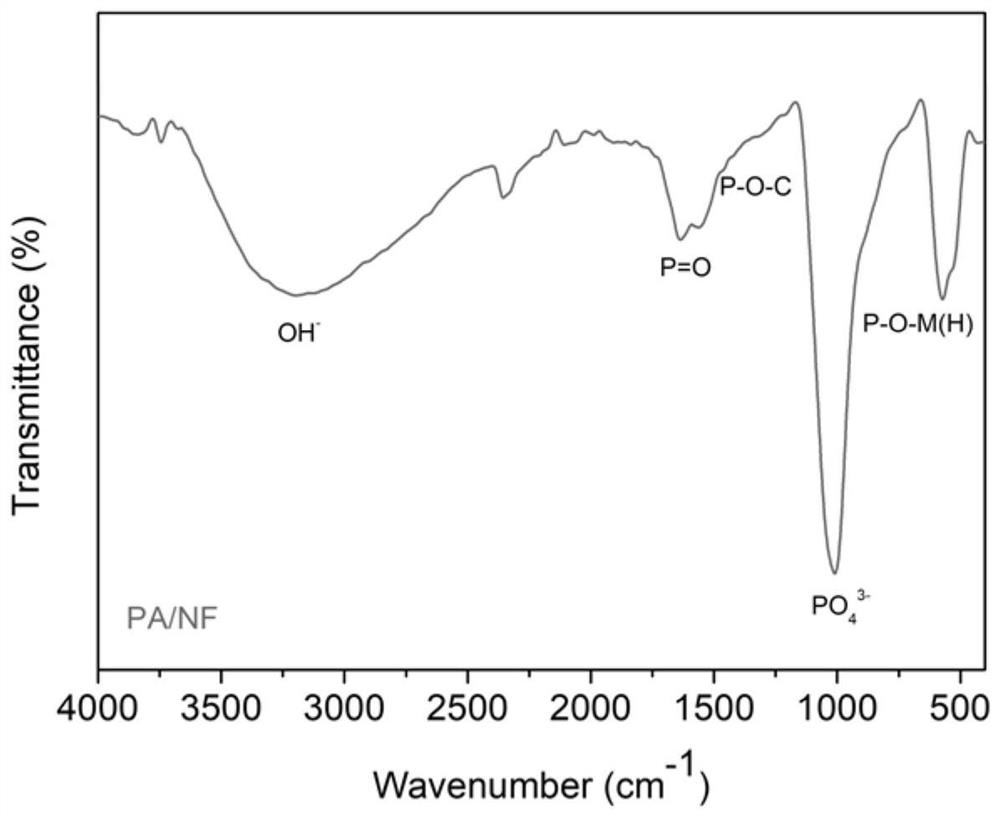

[0026] Step 1: Soak 1cm×3cm×0.2cm nickel foam in 0.3mol / L salt and ultrasonically clean it for 20 minutes to remove the oxide layer and pollutants on the surface, and then perform ultrasonic oscillation treatment in ethanol, acetone and deionized water respectively. Remove excess hydrochloric acid on the surface to obtain pretreated nickel foam. Such as figure 1 As shown, the surface of the pretreated nickel foam is flat and smooth. Then the phytic acid aqueous solution that 73mL mass fraction is 2% is poured in the 100mL polytetrafluoroethylene hydrothermal reactor, and puts into the foamed nickel after the pretreatment, and the hydrothermal reactor is put into blast drying oven, at 120 ℃ under hydrothermal conditions for 10 h, and the reaction kettle was cooled to room temperature. The silvery nickel foam was taken out, washed repeatedly with deionized water and ethanol under ultrasound, and dried at 60 °C to obtain a phytic acid-modified nickel foam electrode (PA / NF). De...

Embodiment 2

[0030] Step 1: Soak 1cm×3cm×0.2cm nickel foam in 0.6mol / L hydrochloric acid and ultrasonically clean it for 20 minutes to remove the oxide layer and pollutants on the surface, and then perform ultrasonic oscillation treatment in ethanol, acetone and deionized water respectively. Remove excess hydrochloric acid on the surface to obtain pretreated nickel foam. Then the phytic acid aqueous solution that 74mL mass fraction is 2.7% is poured in the 100mL polytetrafluoroethylene hydrothermal reactor, and puts into the foamed nickel after the pretreatment, and the hydrothermal reactor is put into blast drying oven, at 150 ℃ under hydrothermal conditions for 12 h, and the reaction kettle was cooled to room temperature. The silvery nickel foam was taken out, washed repeatedly with deionized water and ethanol under ultrasound, and dried at 70°C to obtain a phytic acid-modified nickel foam electrode.

[0031] Step 2: Using a three-electrode system, the phytic acid-modified nickel foam e...

Embodiment 3

[0033] Step 1: Soak 1cm×3cm×0.2cm nickel foam in 0.6mol / L salt and ultrasonically clean it for 20 minutes to remove the oxide layer and pollutants on the surface, and then perform ultrasonic oscillation treatment in ethanol, acetone and deionized water respectively. Remove excess hydrochloric acid on the surface to obtain pretreated nickel foam. Then the phytic acid aqueous solution that 75mL mass fraction is 3.3% is poured in the 100mL polytetrafluoroethylene hydrothermal reactor, and puts into the foamed nickel after the pretreatment, and the hydrothermal reactor is put into blast drying oven, at 180 ℃ for 15 h under hydrothermal conditions, and the reaction kettle was cooled to room temperature. The silvery nickel foam was taken out, washed repeatedly with deionized water and ethanol under ultrasound, and dried at 80°C to obtain a phytic acid-modified nickel foam electrode.

[0034] Step 2: Using a three-electrode system, the phytic acid-modified nickel foam electrode obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com