Ammonia nitrogen recovery device and method for resin regeneration wastewater of fine treatment system in power plant

A technology for resin regeneration and ammonia nitrogen recovery, applied in filtration treatment, water/sewage treatment, chemical instruments and methods, etc., can solve problems such as high residual ammonia nitrogen content in produced water, large consumption of chemicals, and large fluctuations in water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

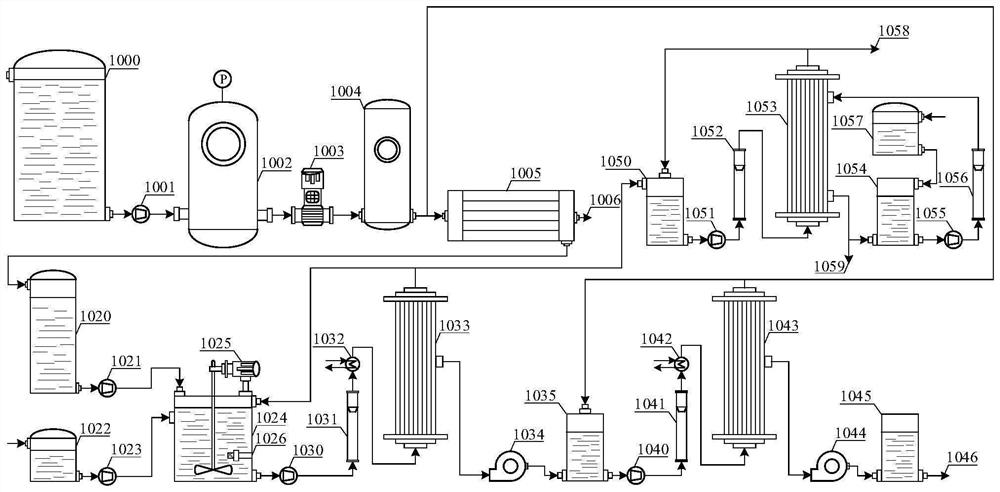

[0061] The first embodiment of the present invention relates to an ammonia nitrogen recovery device for resin regeneration wastewater in a power plant finishing system. as attached figure 1 As shown, the main body of this embodiment includes a fine treatment regeneration wastewater storage tank 1000, a multimedia filter 1002, a reverse osmosis high pressure pump 1003, a security filter 1004, a reverse osmosis 1005, a fine treatment resin regeneration wastewater concentrate storage tank 1020, an alkali Liquid storage tank 1022, mixing tank 1024, first heat exchanger 1032, first degassing membrane module 1033, first vacuum pump 1034, intermediate ammonia water tank 1035, second heat exchanger 1042, second degassing membrane module 1043, the second Two vacuum pumps 1044, product ammonia water tank 1045, deep deammonization tank 1050 for refined resin regeneration wastewater, third degassing membrane module 1053, phosphoric acid circulation tank 1054 and phosphoric acid dosing tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com