A high-strength anti-yellowing polyurethane lamp cover and its preparation method

A technology of anti-yellowing and polyurethane, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as brittleness, affecting the normal use of floor lamps, discoloration, etc., and achieve the effect of improving coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

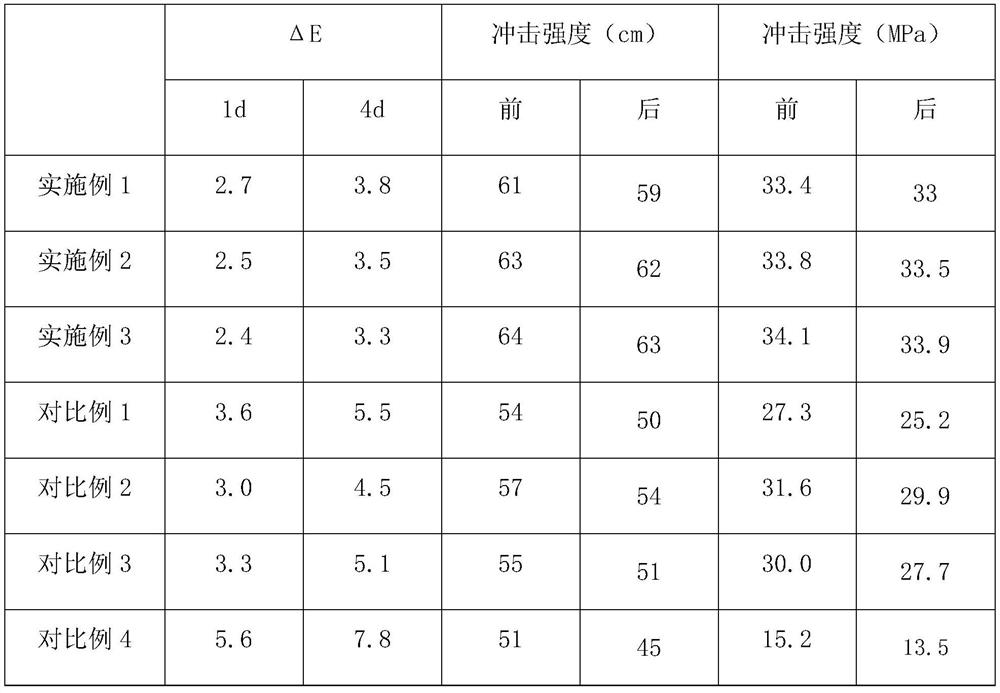

Examples

Embodiment 1

[0034] (1) Prepare the shell:

[0035] Mix hydroxymethylated lignin and distilled water, add sodium hydroxide solution, adjust the pH of the system to 10.5, and raise the temperature to 88°C to obtain a lignin solution; mix cardanol and distilled water, add sodium hydroxide solution, and adjust the pH of the system to 10.5, the temperature was raised to 88° C. to obtain a cardanol solution;

[0036] Mix the lignin solution and the cardanol solution, reflux at 88°C for 100min, add distilled water and hydrochloric acid, adjust the pH of the system to 2.7, precipitate out, let it stand for 2h, filter, wash with distilled water repeatedly until neutral, and vacuum dry at 50°C for 12h to obtain Modified lignin; the consumption of cardanol is 5.0% of lignin quality;

[0037] Take polytetrahydrofuran ether diol for vacuum dehydration at 100°C, cool to 40°C, add toluene diisocyanate, stir in a nitrogen atmosphere, react at 68°C for 1 hour, cool down and vacuum defoam to obtain a prep...

Embodiment 2

[0044] (1) Prepare the shell:

[0045] Mix hydroxymethylated lignin and distilled water, add sodium hydroxide solution, adjust the pH of the system to 11, and raise the temperature to 90°C to obtain a lignin solution; mix cardanol and distilled water, add sodium hydroxide solution, and adjust the pH of the system to 11. Heat up to 90°C to obtain a cardanol solution;

[0046] Mix the lignin solution with the cardanol solution, reflux at 90°C for 120min, add distilled water and hydrochloric acid, adjust the pH of the system to 3.0, precipitate out, let stand for 2.5h, filter, wash with distilled water repeatedly until neutral, and vacuum dry at 60°C for 18h. Obtain modified lignin; the amount of cardanol is 8.5% of lignin quality;

[0047] Take polytetrahydrofuran ether diol for vacuum dehydration at 110°C, cool to 50°C, add toluene diisocyanate, stir in a nitrogen atmosphere, react at 70°C for 1.5h, cool down and vacuum defoam to obtain a prepolymer; add 4,4' -Dithiodiphenyla...

Embodiment 3

[0054] (1) Prepare the shell:

[0055] Mix hydroxymethylated lignin and distilled water, add sodium hydroxide solution, adjust the pH of the system to 11.5, and raise the temperature to 95°C to obtain a lignin solution; mix cardanol and distilled water, add sodium hydroxide solution, and adjust the pH of the system to 11.5, the temperature was raised to 95° C. to obtain a cardanol solution;

[0056] Mix the lignin solution and the cardanol solution, reflux at 95°C for 150min, add distilled water and hydrochloric acid, adjust the pH of the system to 3.2, precipitate out, let stand for 3h, filter, wash with distilled water repeatedly until neutral, and vacuum dry at 70°C for 24h to obtain Modified lignin; the consumption of cardanol is 12% of lignin quality;

[0057] Take polytetrahydrofuran ether diol for vacuum dehydration at 120°C, cool to 60°C, add toluene diisocyanate, stir in a nitrogen atmosphere, react at 75°C for 2 hours, cool down and vacuum defoam to obtain a prepoly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com