Method for producing and preparing ultra-high molecular weight hyaluronic acid by microbial fermentation method

A technology for ultra-high molecular weight and hyaluronic acid, which is applied in the field of production and preparation of ultra-high molecular weight hyaluronic acid, which can solve the problems of high cost and difficult methods for purifying hyaluronic acid, so as to increase the molecular weight, easy to control the fermentation process, and widely used foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

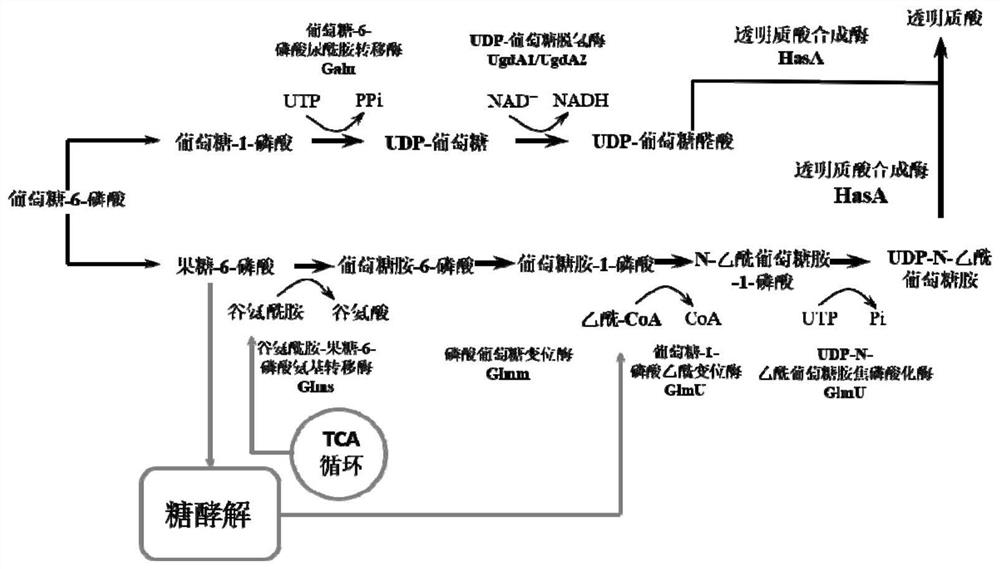

Method used

Image

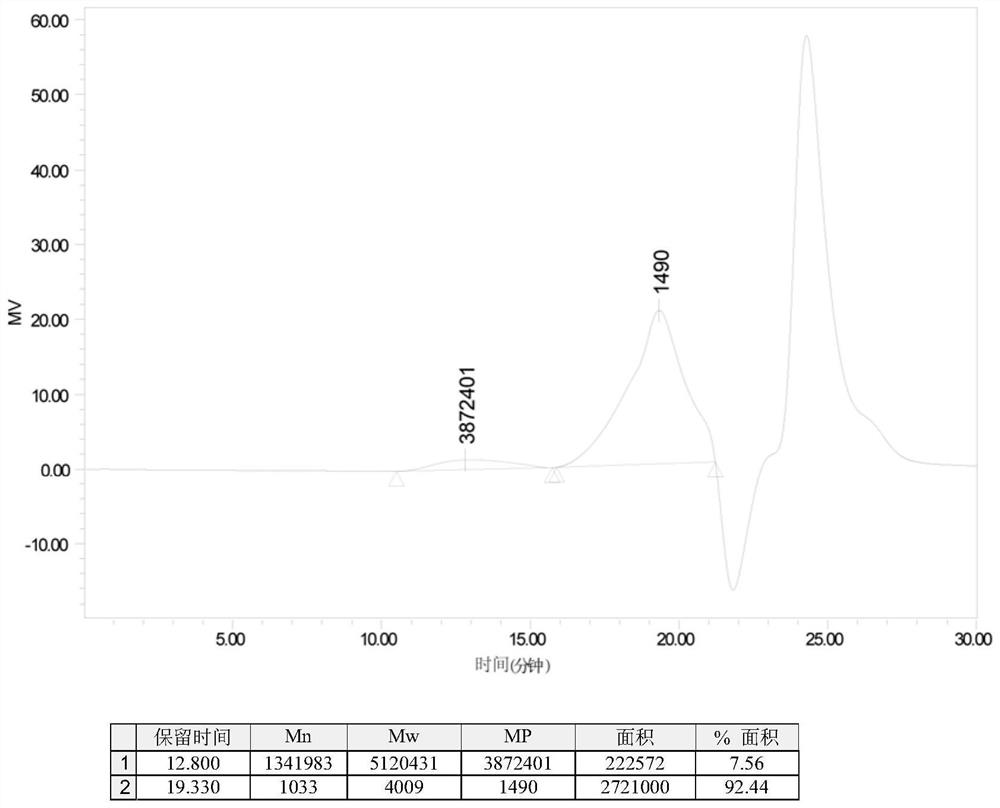

Examples

Embodiment 1

[0031] Embodiment 1: low-temperature fermentation of recombinant Corynebacterium glutamicum produces ultra-high molecular weight hyaluronic acid

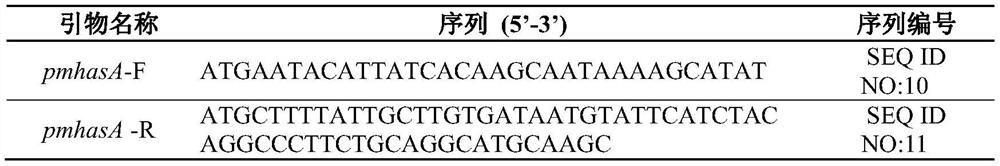

[0032] Step 1: Construct recombinant plasmid to express Pasteurella multocida derived hyaluronan synthase pmHasA

[0033] According to the genome sequence of Pasteurella multocida, the hyaluronic acid synthase gene pmHasA was synthesized by GENEWIZ (Suzhou). The sequence of pmHasA is shown in Gene ID: 11805012. Using the synthesized pmHasA gene sequence as a template, primers pmhasA-F and pmhasA-R were designed for PCR amplification, and then the pmHasA gene sequence was connected to the plasmid pXMJ19 by the T5 exonuclease-dependent assembly (TEDA) method to construct the recombinant expression plasmid pXMJ19- pm has A.

[0034] Table 1 constructs the primers used for the recombinant plasmid expressing hyaluronan synthase

[0035]

[0036] Step 2: construct the recombinant plasmid that RBS weakens and expresses hyaluronan synt...

Embodiment 2

[0070] Embodiment 2: Recombinant Corynebacterium glutamicum fermentation tank horizontal low-temperature fermentation produces ultra-high molecular weight hyaluronic acid

[0071] 1. Medium

[0072] Fermentation medium: corn steep liquor dry powder 20g / L, (NH4) 2 SO 4 20g / L, KH 2 PO 4 1g / L, K 2 HPO 4 1g / L, MgSO 4 0.25g / L, MOPS (3-morpholine propanesulfonic acid) 4.2g / L, glucose concentration 40g / L.

[0073] 2. Culture method

[0074] Pick the monoclonal cells from the plate, place them in a shaking tube filled with 5mL of BHIS medium, and culture them overnight at 28°C and 220rpm.

[0075] with initial OD 600 Take the seed liquid cultivated overnight for an inoculum size of 0.1, and transfer it to a baffle shake flask containing 25 mL of fermentation medium. OD 600 After rising to 10-15, transfer to a 3L fermenter with 10% inoculum, so that the initial OD of the bacteria in the fermenter 600 1-1.5. After culturing at 28℃, 220rpm for 3h 600 After rising to abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com