Method for adsorbing and purifying impurities by using high-purity benzyl chloride

A benzyl chloride, high-purity technology, applied in the field of compound purification and impurity removal, can solve the problems of complex structure of rectification tower, increase of process complexity, low production efficiency, etc., and achieve the effect of improving product purity, reducing pollution and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

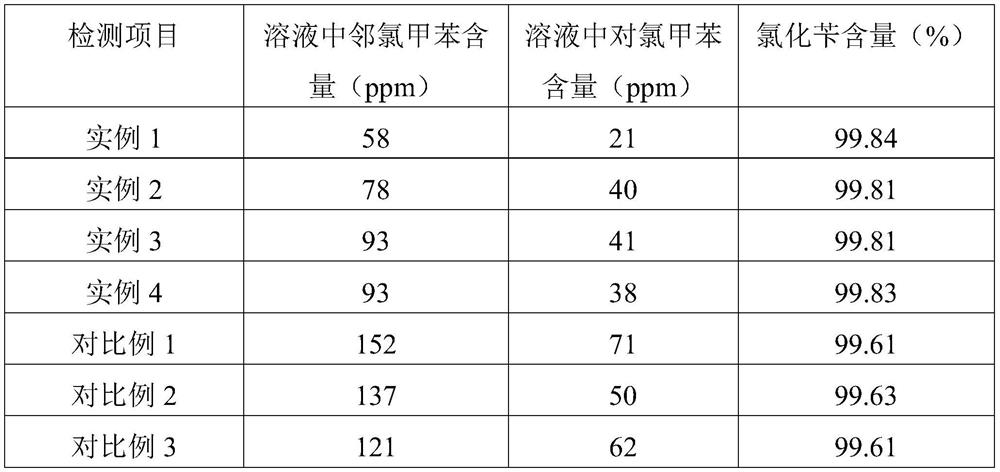

example 1

[0034] Configure the critical glue solution of ammonium surfactant hexamethyltrimethylammonium bromide, impregnate activated carbon in solution, oscillated at 30 ° C for 6 h, then washed unreacted surfactants with deionized water, and finally Filtration, dried to obtain modified activated carbon. The modified activated carbon was activated at 300 ° C in a muffle, 0.79 g of a sized adsorption device (toluene content 245 ppm, o-chlorozene content of 20 mL), was grounded to 20 mL of the adsorption device (toluene content of 245 ppm, o-chlorohydrophylene content 137 ppm) The chlorobenzene content is 66 ppm, the benzaldehyde content of 669 ppm, and the remaining impurities 3725 ppm) The injection pump enters the U-tube in the U-tube at a rate of 5 mL / h, and 58 ppm is collected at the adsorption column exit after the adsorption post. 21 ppm, toluene content of 38 ppm, benzaldehyde content 129 ppm, and the remaining impurities 1373 ppm high purity chlorinated chlorinated chlorinated ch...

example 2

[0036] The critical gum solution of sodium surface active dodecyl sulfate was configured, and the activated carbon was immersed in a solution, oscillated at 30 ° C for 6 h, then washed the unreacted surfactant with deionized water, and finally filtered through vacuum, dried Modified activated carbon. The modified activated carbon was placed under the conditions of the muffle at 300 ° C for 3 h, 20 to 30 mesh, 8.99 g of the adsorption device of 20 ml, and a chlorinated material (toluene content of 245 ppm, o-chlorohydrophylene content 137 ppm) The chlorobide content is 41 ppm, the benzaldehyde content of 669 ppm, and the remaining impurities 3725 ppm) The injection pump enters the U-tube at a rate of 8 ml / h, and after 95 minutes, the other side is collected at the other side of the material to 78 ppm, pair The chlorobenyl is 10 ppm, the toluene content is 92 ppm, and the benzaldehyde content is 202 ppm, and the remaining impurities 1482 ppm high purity chlorinated chlorinated chl...

example 3

[0038]Configuring a colloidal solution critical dodecylbenzene sulfonate surfactants, activated carbon is immersed in the solution, shaken at 30 deg.] C 6h, and then rinsed with deionized water, unreacted surfactant, and finally through vacuum filtration, and dried to give modified activated carbon. Under the activation conditions of the modified activated carbon placed in a muffle furnace of 300 deg.] C 3h, ground to 20-30 mesh, was charged 20mL size of the adsorbing device 10.07 g, chlorotoluene starting material content of benzyl chloride (content of 245 ppm toluene, o- 137 ppm, chlorotoluene content of 41ppm, benzaldehyde content is 669ppm, the remaining impurities 3725ppm) with a syringe pump 10mL h speed / into the U-tube, after 64 minutes into the other side of the sample collected at the o-chlorotoluene content of 93ppm in the raw material, 41ppm chlorine content of toluene, the toluene content of 134 ppm, 209 ppm benzaldehyde content, the remaining impurities 1368ppm high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com