Rubber sealing material for bearing and resisting mixed fuel system and preparation process of rubber sealing material

A hybrid fuel system and rubber sealing technology, applied in the field of rubber sealing materials, can solve the problems of low hardness, not meeting the basic requirements of sealing materials, etc., and achieve the effects of improving aging resistance, enhancing oil resistance, and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

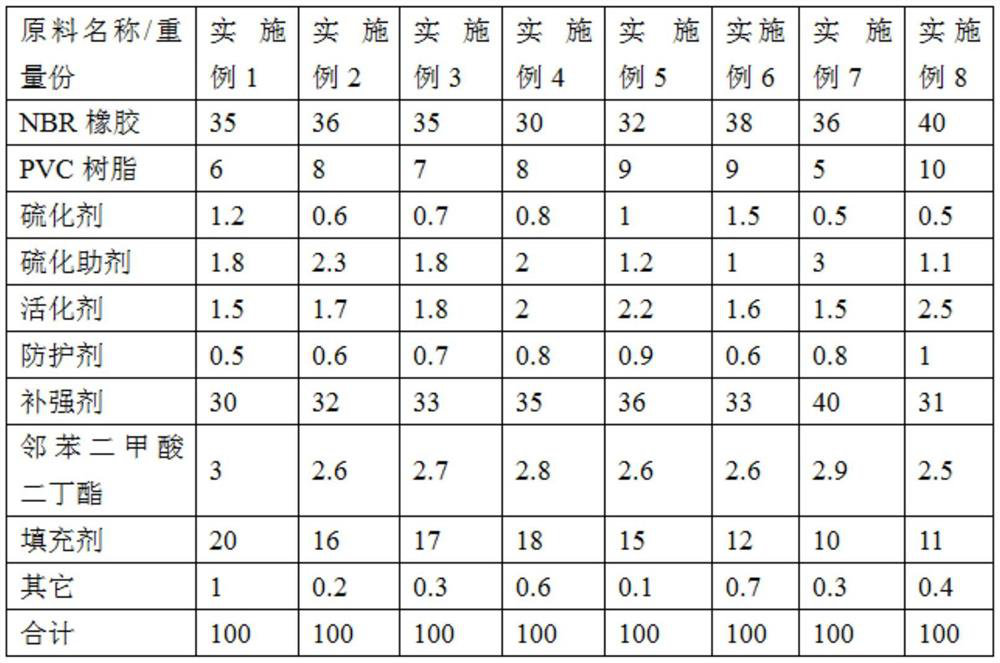

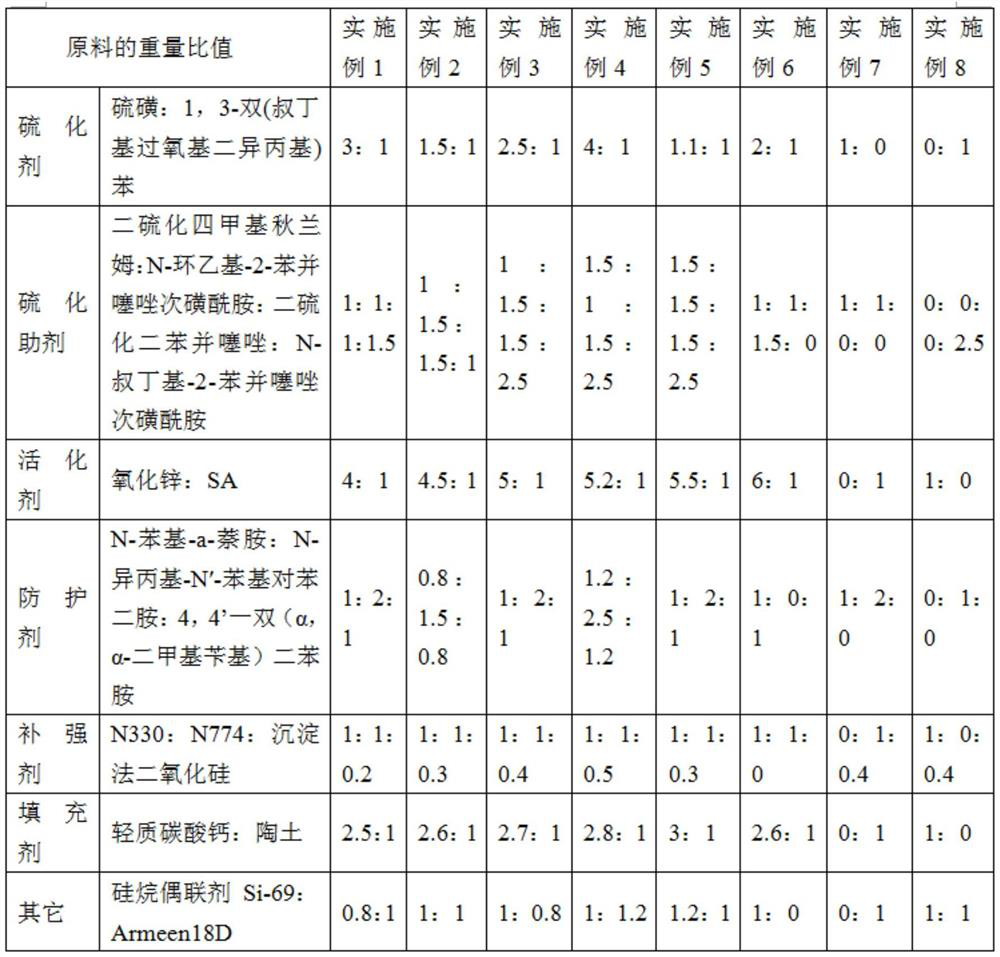

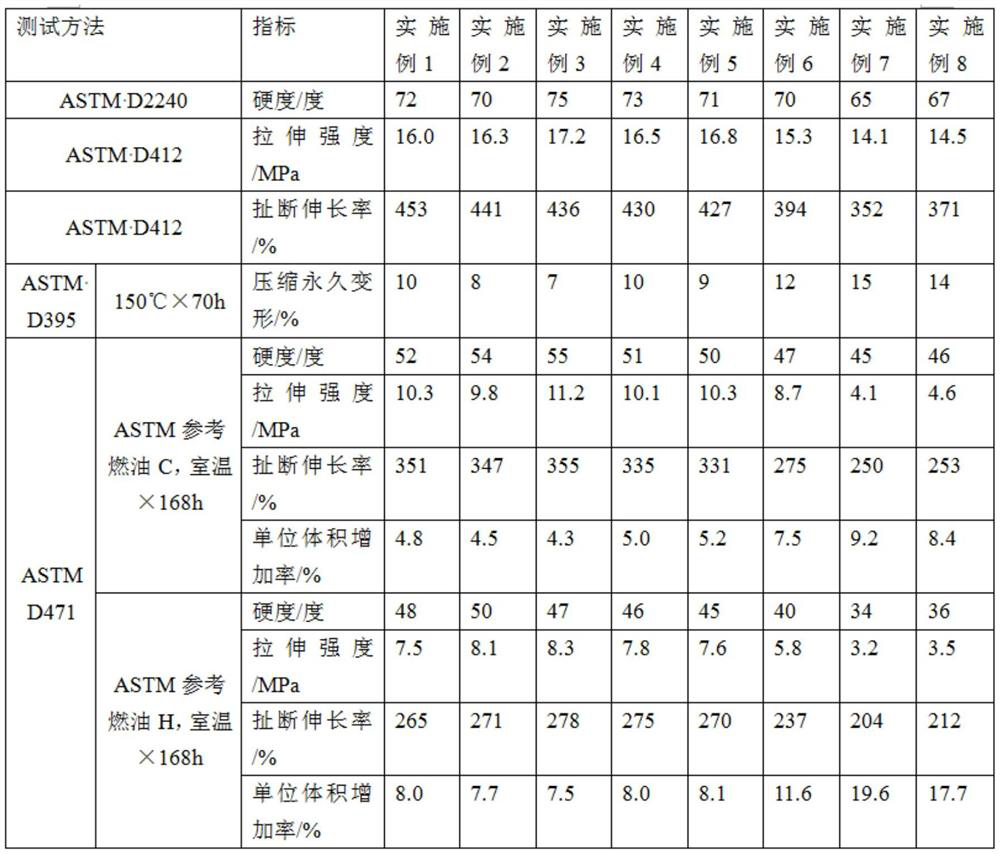

[0036] Weigh the raw materials shown in Table 1 and Table 2 respectively, and set them aside; add NBR rubber and PVC resin to the internal mixer, heat up to 80°C, pre-mix at 70r / min for 25min, continue to heat up to 155°C, 200r / min Mix for 12 minutes to obtain the first mixture; keep the temperature constant, add vulcanizing agent and activator to the first mixture, and mix for 8 minutes; continue to add protective agent, reinforcing agent and softener, and mix for 8 minutes; then add Filler and other additives, mixed for 8 minutes; at the temperature of the rollers of the mill at 50°C±5°C, the speed ratio of the rollers of the mill is 1:1.27, the line speed of the front roller is 23.44m / min, and the vulcanization aid is added , kneading for 2 minutes, the left and right three-quarter cutters each three times, then adjust the roller distance below 1mm, thin pass and make a triangle bag six times, loosely fall off, the thickness of the rubber material is controlled between 3-4mm...

Embodiment 2

[0038] Weigh the raw materials shown in Table 1 and Table 2 respectively, and set them aside; add NBR rubber and PVC resin to the internal mixer, heat up to 75°C, pre-mix at 80r / min for 20min, continue to heat up to 145°C, 300r / min Mix for 15 minutes to obtain the first mixture; keep the temperature constant, add vulcanizing agent and activator to the first mixture, and mix for 10 minutes; continue to add protective agent, reinforcing agent and softener, and mix for 5 minutes; then add Filler and other additives, mixed for 5 minutes; at the temperature of the roll of the mill at 50°C±5°C, the speed ratio of the roll of the mill is 1:1.27, the line speed of the front roll is 23.44m / min, add the vulcanization aid , kneading for 2 minutes, the left and right three-quarter cutters each three times, then adjust the roller distance below 1mm, thin pass and make a triangle bag six times, loosely fall off, the thickness of the rubber material is controlled between 4-5mm, and stand stil...

Embodiment 3

[0040] Weigh the raw materials shown in Table 1 and Table 2 respectively, and set them aside; add NBR rubber and PVC resin to the internal mixer, heat up to 85°C, pre-mix at 50r / min for 30min, continue to heat up to 160°C, 120r / min Mix for 10 minutes to obtain the first mixture; keep the temperature constant, add vulcanizing agent and activator to the first mixture, and mix for 5 minutes; continue to add protective agent, reinforcing agent and softener, and mix for 10 minutes; then add Filler and other additives, mixed for 10min; at the temperature of the roll of the mill at 50°C±5°C, the speed ratio of the roll of the mill is 1:1.27, the line speed of the front roll is 23.44m / min, add vulcanization aid , kneading for 2 minutes, the left and right three-quarter cutters each three times, then adjust the roller distance below 1mm, thin pass and make a triangle bag six times, loosely fall off, the thickness of the rubber material is controlled between 3.5-4.5mm, and stand for 24 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com