Suckling pig creep feed with balanced nutrition and conditioning effect

A technology of nutritionally balanced and trough feeding, applied in the field of feeding troughs for suckling pigs, can solve the problems of affecting the digestion of suckling pigs, poor nutritional ratio, affecting palatability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A suckling pig creep feed with balanced nutrition and conditioning effect, comprising the following components in parts by weight:

[0028] 9-11 parts of Peruvian steam fish meal, 36-44 parts of rice flour, 12-15 parts of fermented soybean meal, 10-13 parts of puffed soybean, 9-10 parts of puffed corn, 0.9-1.1 part of soybean oil, 4.5-5.5 parts of whey powder, 2.7-3.3 parts of glucose, 1-1.3 parts of sodium chloride, 0.9-1.1 parts of calcium hydrogen phosphate, 0.3-0.4 parts of calcium carbonate, 0.09-0.11 parts of compound essential oil, 0.3-0.5 parts of multivitamins, 0.3-0.5 parts of trace elements , amino acid combination 1.4-1.8 parts.

[0029] The amino acid combination is prepared by mixing lysine, threonine, tryptophan, valine and methionine in a ratio of 25:3:3:3:8.

[0030] The preparation process of suckling pig creep feed with balanced nutrition and conditioning effect is as follows:

[0031] Step 1: Put corresponding proportions of lysine, threonine, tryp...

Embodiment 2

[0041] A suckling pig creep feed with balanced nutrition and conditioning effect, comprising the following components in parts by weight:

[0042] 10 parts of steamed fish meal imported from Peru, 40 parts of rice flour, 14 parts of fermented soybean meal, 12 parts of puffed soybean, 10 parts of puffed corn, 1 part of soybean oil, 5 parts of whey powder, 3 parts of glucose, 1.2 parts of sodium chloride, calcium hydrogen phosphate 1 part, 0.35 part of calcium carbonate, 0.1 part of compound essential oil, 0.4 part of multivitamin, 0.35 part of trace element.

[0043] The amino acid combination is prepared by mixing lysine, threonine, tryptophan, valine and methionine in a ratio of 25:3:3:3:8.

[0044] The preparation process of suckling pig creep feed with balanced nutrition and conditioning effect is as follows:

[0045] Step 1: Put corresponding proportions of lysine, threonine, tryptophan, valine, and methionine into the mixer, mix the mixture at low temperature, and obtain...

Embodiment 3

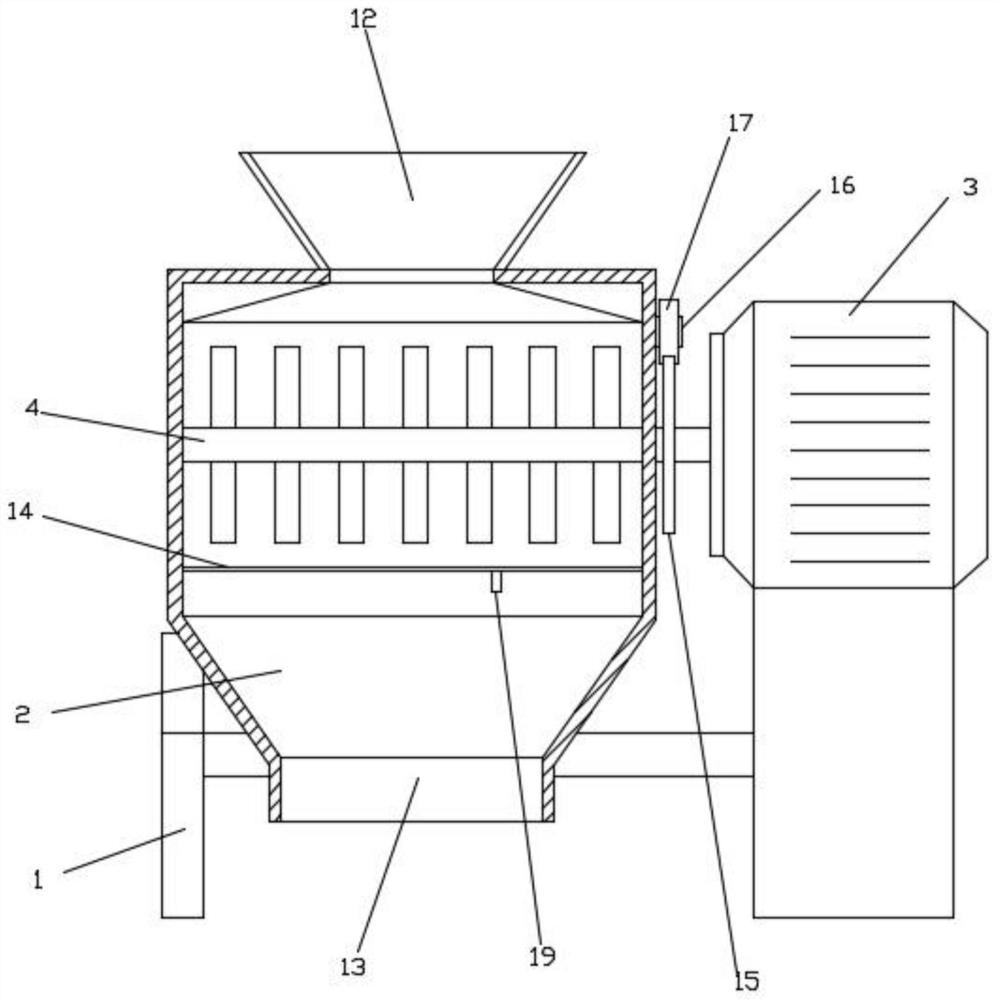

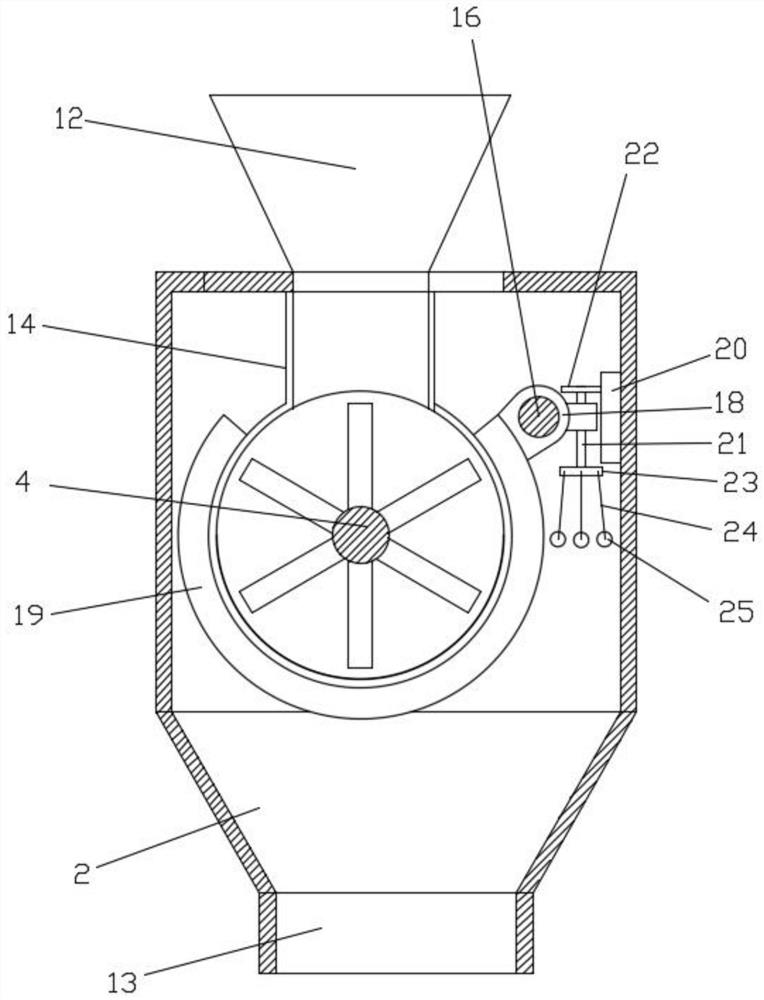

[0057] On the basis of Example 2, such as Figure 1-2 As shown, the ultrafine pulverizer includes a device bracket 1, a pulverization box 2, a drive motor 3, and a pulverization shaft 4;

[0058] The crushing box 2 and the driving motor 3 are all installed on the device bracket 1, the upper part of the crushing box 2 is provided with a feed inlet 12, the bottom is provided with a discharge port 13, and a screen cylinder 14 is installed inside the crushing box 2, and the screen cylinder 14 and The feeding port 12 is connected, the crushing shaft 4 is installed in the screen cylinder 14, the crushing shaft 4 is connected with the output shaft of the driving motor 3, the driving gear 15 is installed on the crushing shaft 4, and the reciprocating screw rod 16 is installed in the crushing box 2 for rotation. , the end of the reciprocating screw rod 16 is equipped with a driven gear 17, the driven gear 17 meshes with the driving gear 15, a sliding seat 18 is installed on the recipro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com