Preparation method of soap-free emulsion for concrete protective coating and equipment

A technology of protective coatings and soap-free emulsions, applied to laboratory containers, chemical instruments and methods, heating or cooling equipment, etc., can solve problems such as poor bonding performance and poor water resistance, achieve low surface free energy, improve water resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

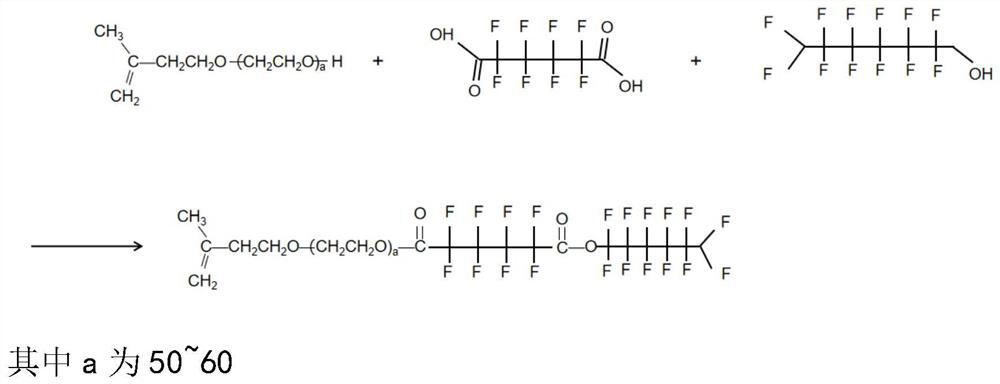

[0032] Example 1: Method for preparing soap emulsion with concrete protective coatings, such as figure 1 , Including the following method,

[0033] The first step: isobutylene polyoxyethylene ether and whole fluoropentaic acid, dodexyl heptanol in accordance with molar ratio 1: 1: 1, in concentrated sulfuric acid as a catalyst, carried out at 120 degrees Celsius body;

[0034]Step 2: Take the fluorine-containing monomer, butyl methacrylate, vinyl trimethoxysilane is monomer, sodium styrene sulfonate, 2-acrylamide-2-methylpropulfonic acid is ionic type The copolymerization of the emulsifier, adding distilled water, stirred evenly, warmed to 70 ° C, and an emulsion polymerization reaction of the initiator hypervonate is added;

[0035] The third step is: the polymerization time is 2 h, and the incubation of 1H is finally high fluorine-free soon fluorocarbon emulsion.

[0036] The amount of fluorine-containing monomer is 75 g, the amount of butyl methacrylate is 10 g, the amount of v...

Embodiment 2

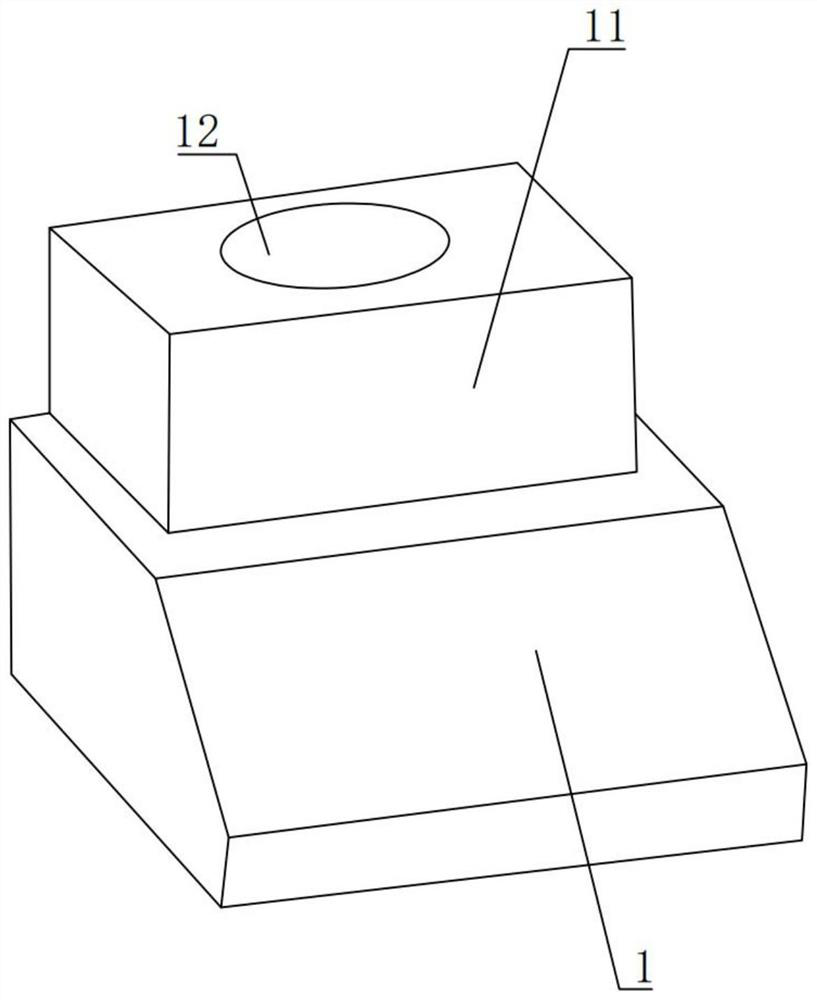

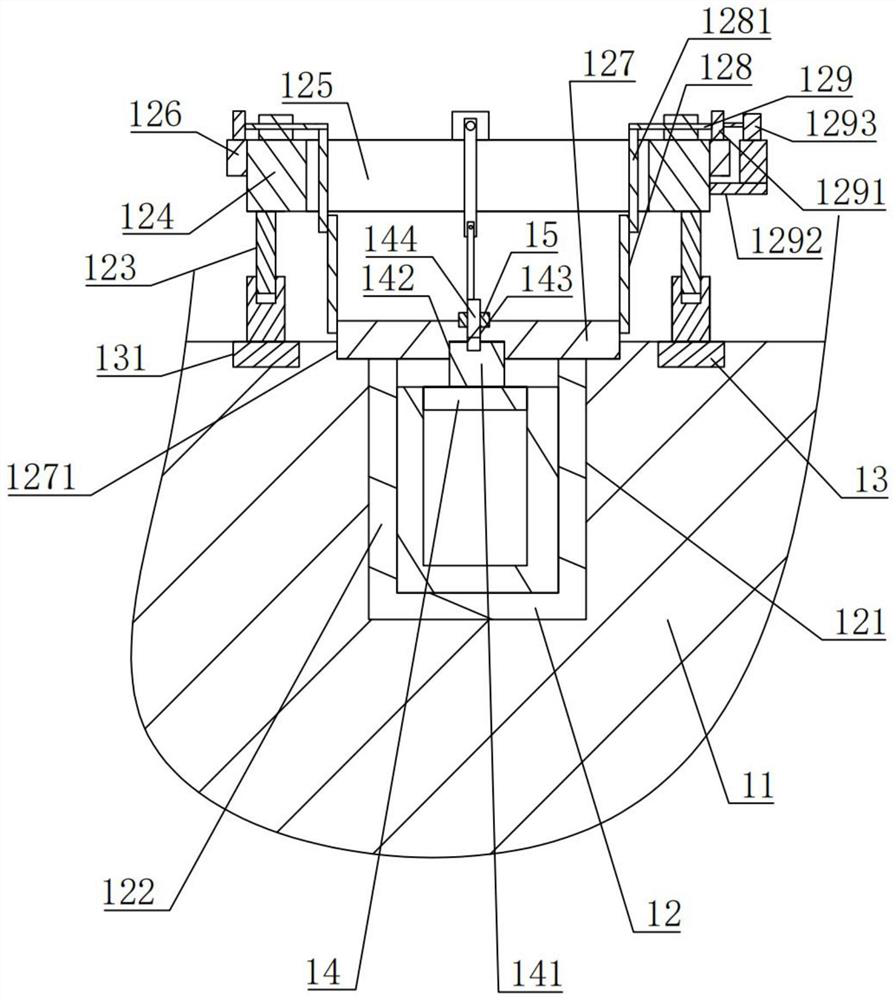

[0049] Example 2: An apparatus in the preparation of soap-free emulsion according to the first embodiment, such as figure 2 and image 3 The heating device includes a base 1 and a heating sleeve insulating housing 11 disposed on the base 1, the intermediate of the heating sleeve insulating housing 11 is provided with a placement tank 121 and the rendering groove 121 is fixed to the heating kit body 12, and the heating kit body 12 is annular and The heating bottle 122 is supplied, and the heating sleeve insulating housing 11 is detachably coupled to the closure of the closed groove 121 in the heating cylinder 122 is placed in the heating kit body 12. The heating kit body 12 can be a electric heating wire, the closure block closed the slot 121, facilitating the heating kit body 12 to heat the heating bottle 122.

[0050] like image 3 and Figure 4 The closure includes a detachable connection to a plurality of vertical rods 123 on the end face of the heating sleeve insulating housing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com