Preparation method of pure or composite hexagonal boron nitride densified macroscopic body

A technology of hexagonal boron nitride and macroscopic bodies, which is applied in the field of preparation of hexagonal boron nitride compacted macroscopic bodies, can solve the problem of high forming temperature of hexagonal boron nitride compacted macroscopic bodies, increase the contact area between layers and improve the strength , reduce the effect of high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0043] The first specific embodiment of the present invention provides a kind of preparation method of pure hexagonal boron nitride compacted macroscopic body, it comprises the following steps:

[0044] (1) obtaining raw materials, the raw materials are hexagonal boron nitride nanosheet powder, and the solvent content in the raw materials is 0-10wt%;

[0045](2) Hot pressing the raw material in step (1) at a temperature of 25-500° C. to obtain the hexagonal boron nitride densified macroscopic body.

[0046] The second specific embodiment of the present invention provides a method for preparing a composite hexagonal boron nitride compacted macroscopic body, comprising the following steps:

[0047] (1) Obtain raw materials, the raw materials contain hexagonal boron nitride nanosheet powder and additives, the solvent content in the raw materials is 0-10wt%, and the mass percentage of the additives in the raw materials is less than 50%;

[0048] (2) Hot pressing the raw material ...

Embodiment 1

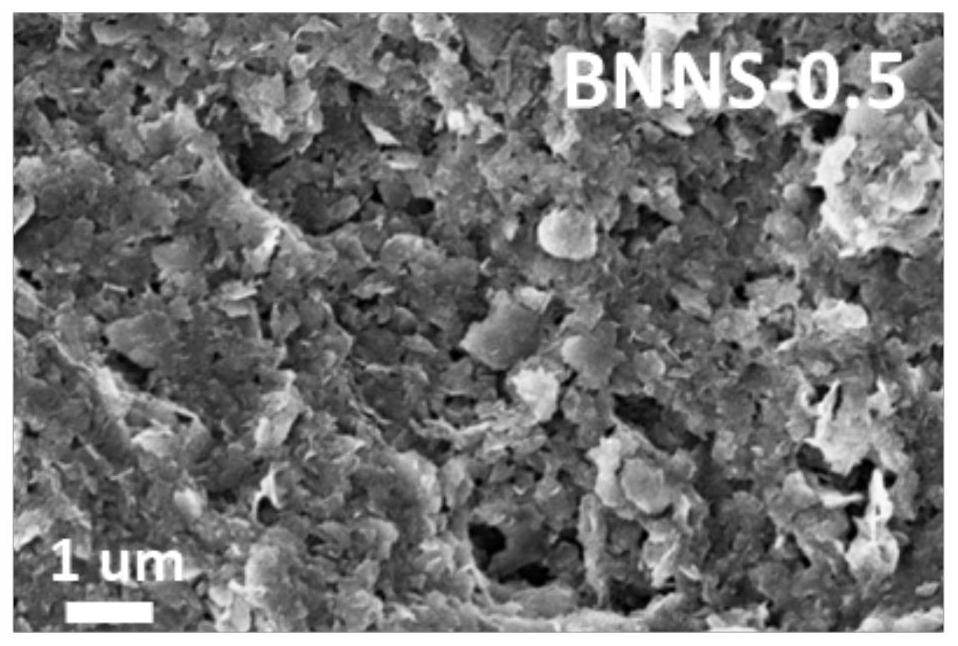

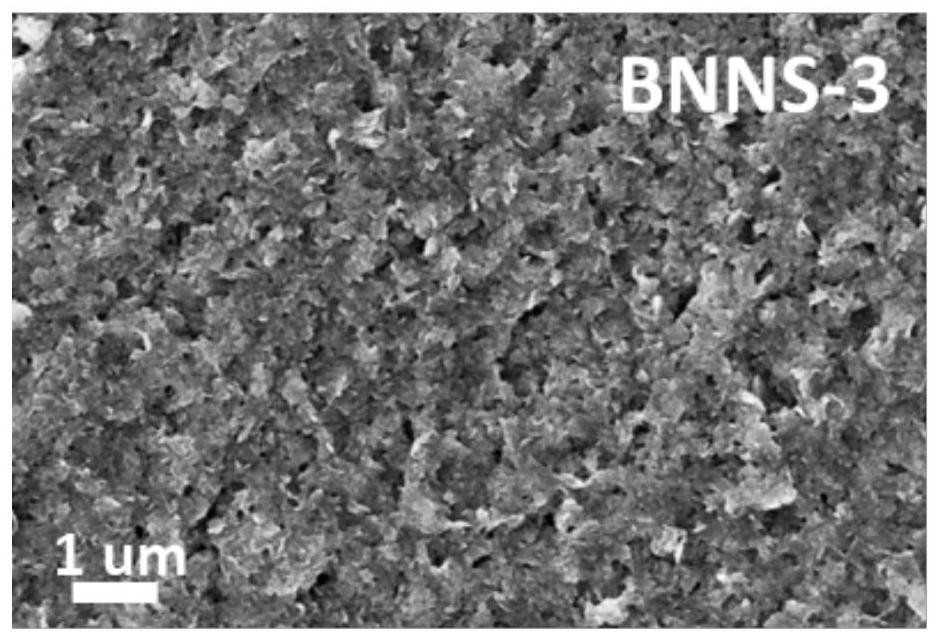

[0062] (1) Take 2 g of urea-assisted mechanical exfoliation of commercial hexagonal boron nitride (Momentive, PT110) hexagonal boron nitride nanosheets (purity 99.5wt%, average diameter 200nm, average thickness 1nm) dissolved in 1L deionized water, ultrasonic After uniform dispersion, filter with nylon membrane (pore size 0.2μm), and add the filtered powder to 200ml deionized water again, sieve the nanosheets by centrifugation at 500rpm and 3000rpm respectively, and finally pass the supernatant through a lyophilizer Drying (-50°C, 0.1bar, 12h) to obtain hexagonal boron nitride nanosheet powder, its water content is about 5wt%, and it is marked as BNNS-0.5 (representing the nanosheet obtained by sieving at 500 rpm) and BNNS-3 (represents nanosheets obtained by sieving at 500 rpm).

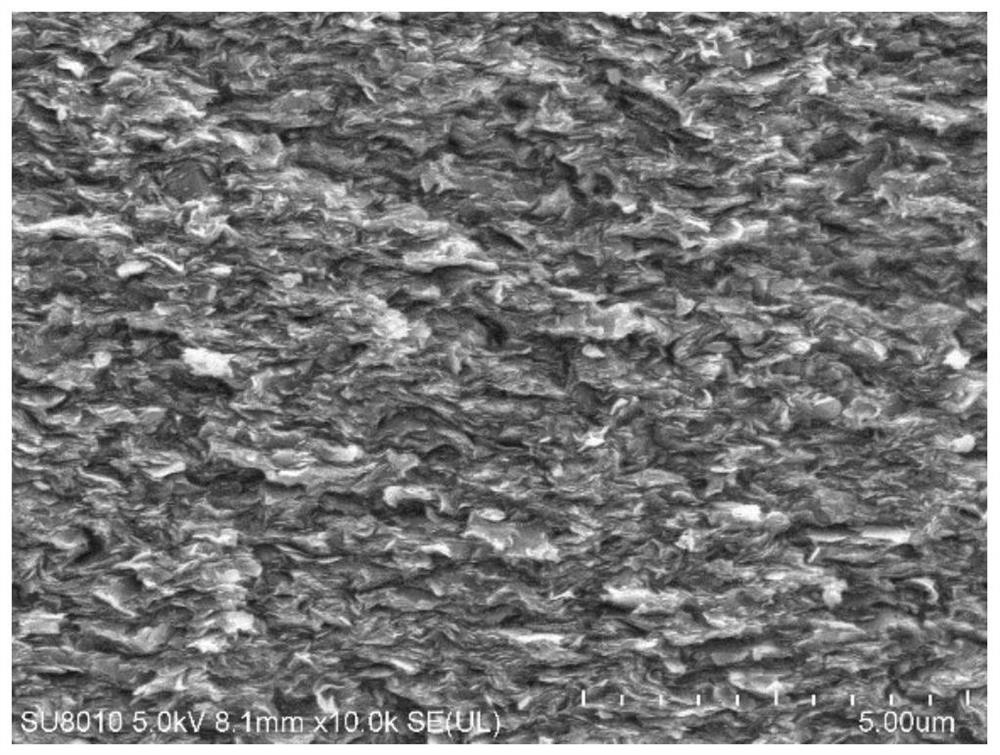

[0063] (2) Take 1.2g of the hexagonal boron nitride nanosheet powder BNNS-3 prepared above and put it into a cylindrical mold steel mold with a diameter of 13mm. The hot pressing conditions are: 25°...

Embodiment 2

[0068] (1) Get the hexagonal boron nitride nanosheets (purity 99wt%, sheet diameter 0.2 ~ 1 μm, sheet thickness 2 ~ 50nm) obtained by ultrasonic peeling of 2g isopropanol, and mix it evenly with polyvinyl alcohol (PVA) aqueous solution, by mass percentage Calculated, the hexagonal boron nitride is 50wt%, and the polyvinyl alcohol content is 50wt%. After the mixed slurry is rapidly cooled to solid, freeze-dried to obtain hexagonal boron nitride-polyvinyl alcohol composite powder, the water content of which is 5 wt%.

[0069] (2) Prepare the composite powder obtained above by hot-pressing under the hot-pressing equipment in step (2) of Example 1 to obtain the hexagonal boron nitride-polyvinyl alcohol composite macroscopic body, and the specific hot-pressing parameters are 90°C, Hot pressing at 375MPa for 1h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com