A method and equipment for separating different rare earth elements in rare earth concentrates by high-gravity steps

A technology of rare earth concentrates and rare earth elements, applied in the direction of improving process efficiency, etc., can solve limited and other problems, and achieve the effect of green and efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Continuous step separation of Ce, La, Pr, Nd in rare earth concentrate:

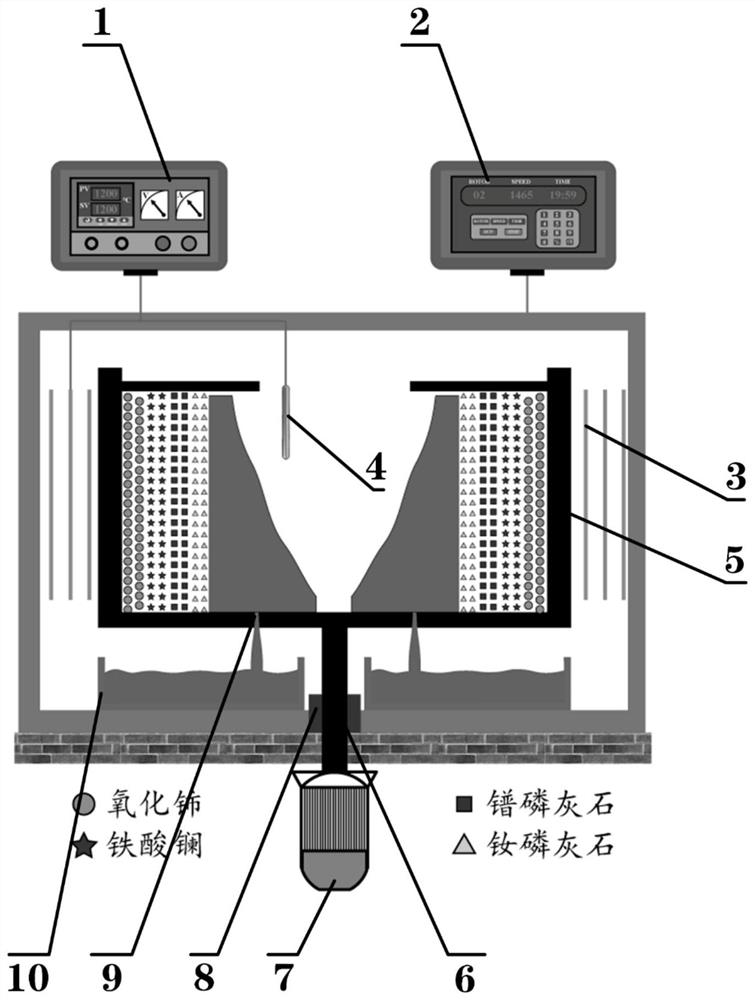

[0050] Step 1. Put 200kg of Baiyun Obo rare earth concentrate into a high-gravity high-temperature reactor, raise the temperature to 1590°C, and keep it warm for 20 minutes until the rare earth concentrate is fully melted.

[0051] Step 2. Continuously lower the temperature of the rare earth concentrate melted in step 1 at a cooling rate of 5°C / min. At the same time, turn on the centrifugal rotation, control the gravity coefficient inside the reactor to G=500, and use supergravity to drive the smelting zone of different rare earth elements. Different rare earth phases realize stepwise interphase transfer and separation.

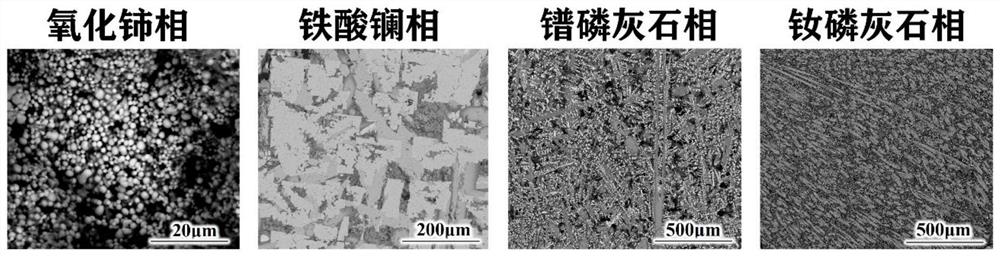

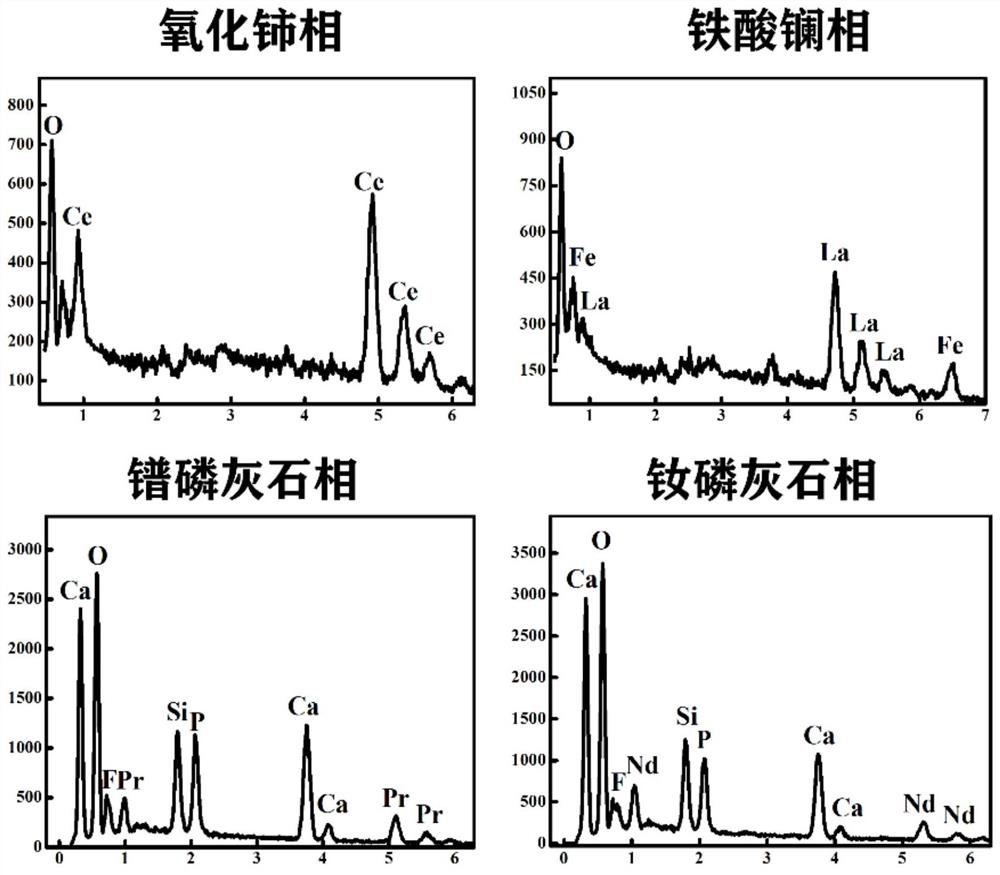

[0052] Step 3. First, the temperature is lowered to 1500-1400° C., and a supergravity field is continuously applied in the single melting zone of Ce (cerium), so that Ce is continuously enriched into cerium oxide, and continuous separation of cerium oxide phase is realized.

[0...

Embodiment 2

[0060] Step-by-step separation of Ce, La, Pr, Nd in rare earth concentrate:

[0061] Step 1. Put 400kg of Baiyun Obo rare earth concentrate into a high-gravity high-temperature reactor, raise the temperature to 1510°C, and keep it warm for 40 minutes until the rare earth concentrate is fully melted.

[0062] Step 2. Cool the rare earth concentrate melted in step 1 to the smelting interval of different rare earth elements step by step at a cooling rate of 2°C / min, then turn on the centrifugal rotation, control the gravity coefficient G=1000 inside the reactor, and use supergravity Drive different rare earth phases to achieve step-by-step interphase transfer and separation.

[0063] Step 3. Firstly, the temperature is lowered to 1500-1400° C. to achieve single eluting crystallization of Ce (cerium), and Ce is fully enriched into cerium oxide. After the eluting is completed, a supergravity field is applied to realize phase separation of cerium oxide.

[0064] Step 4. Then lower ...

Embodiment 3

[0071] The difference from Embodiment 2 is that the gravity coefficient G=2000.

[0072] In this embodiment, the recovery rate of Ce in the cerium oxide phase is 99.67%, the recovery rate of La in the lanthanum ferrite phase is 99.84%, the recovery rate of Pr in the praseodymium apatite phase is 99.10%, and the recovery rate of Nd in the neodymium apatite phase is 99.31%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com