Water-soluble non-woven fabric mask and preparation method thereof

A water-soluble, cloth mask technology, used in non-woven fabrics, pharmaceutical formulations, rayon manufacturing, etc., can solve the problems of low spinning efficiency, difficult to spin forming fibers, unfavorable large-scale production, etc., to improve spinnability. , easy to use, maintenance effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] A preparation method of any one of the above water-soluble non-woven facial masks, comprising the following steps:

[0055] S1. preparing a water-soluble spinning solution comprising polyvinyl alcohol, water-soluble chitosan and hyaluronic acid;

[0056] In step S1, under step temperature conditions of 25-90°C and a stirring rate of 100-300r / min, PVA, water-soluble chitosan, hyaluronic acid and auxiliary materials are added to the solvent water in batches, and mechanically Stir for 1-3 hours to prepare a water-soluble spinning solution.

[0057] Preferably, the preparation process of the mixed spinning solution is: in the process of continuously stirring the solvent water at a stirring rate of 100-300r / min, adding PVA and water-soluble chitosan in sequence, wherein the temperature of the solvent water is controlled at 90°C and below.

[0058] Preferably, after adding the water-soluble chitosan, the temperature in the mixed solution is controlled below 80°C.

[0059] ...

Embodiment 1

[0071] Embodiment 1 of the present invention provides a kind of preparation method of water-soluble non-woven facial mask, comprises the steps:

[0072] S1, preparation of mixed spinning solution: Add PVA, water-soluble chitosan, hyaluronic acid and auxiliary materials to the solvent water in batches under the step temperature condition of 25-90°C and the stirring rate of 300r / min, and carry out Mechanically stirring for 2.5 hours to prepare a mixed spinning solution;

[0073] In the mixed spinning solution, the preparation of each component is by mass percentage as follows:

[0074]

[0075] The specific process of preparation is:

[0076]S11, in the process of continuously stirring the solvent water at a stirring rate of 300 r / min, add PVA and water-soluble chitosan in sequence, wherein the temperature of the solvent water is controlled at 90° C. or below.

[0077] S12, after adding the water-soluble chitosan, the temperature in the mixed solution is controlled below 80...

Embodiment 2-6 and comparative example 1-4

[0082] The difference from Example 1 lies in: the raw material preparation ratio and the settings of the centrifugal spinning process are different, as shown in Table 1 below.

[0083] Table 1 embodiment 1-7 and the process parameter and test result of comparative example 1-4

[0084]

[0085]

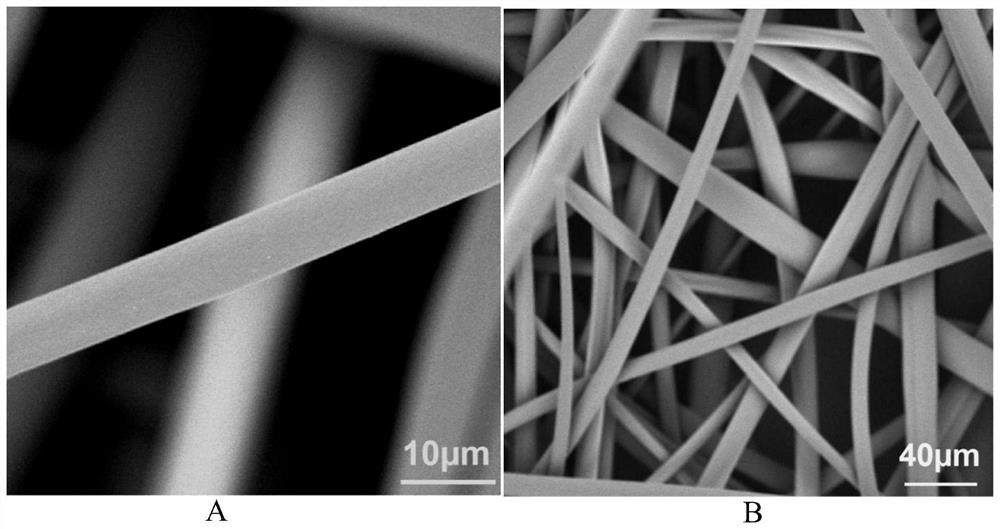

[0086] The electron micrograph of the water-soluble non-woven facial mask that embodiment 1 prepares is as figure 1 shown. from figure 1 with Image 6 It can be seen from the figure that the diameter distribution of the ultrafine fibers of the water-soluble non-woven mask prepared in Example 1 is uniform, mainly concentrated in the fiber fineness of about 9-10um, and the fiber diameter is distributed in the range of 0.5-14μm.

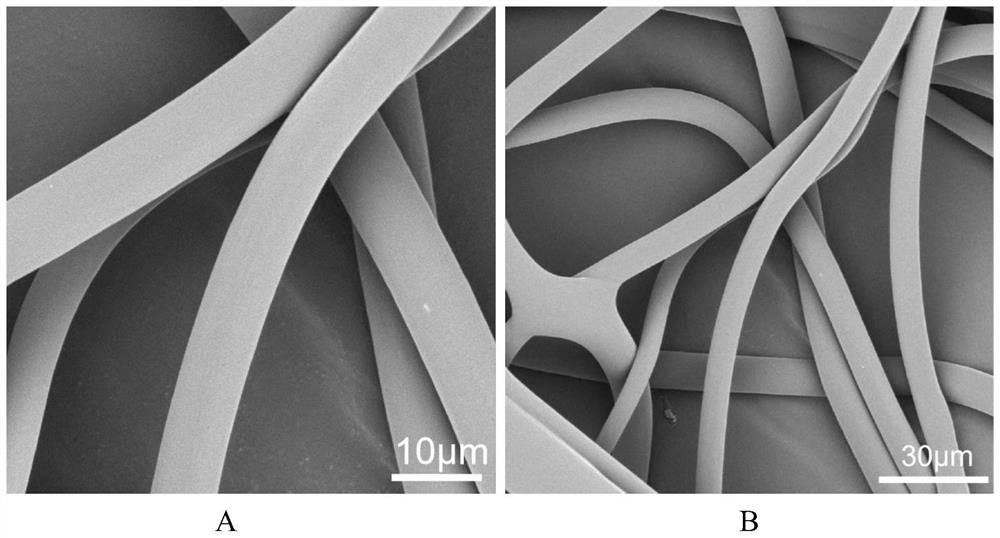

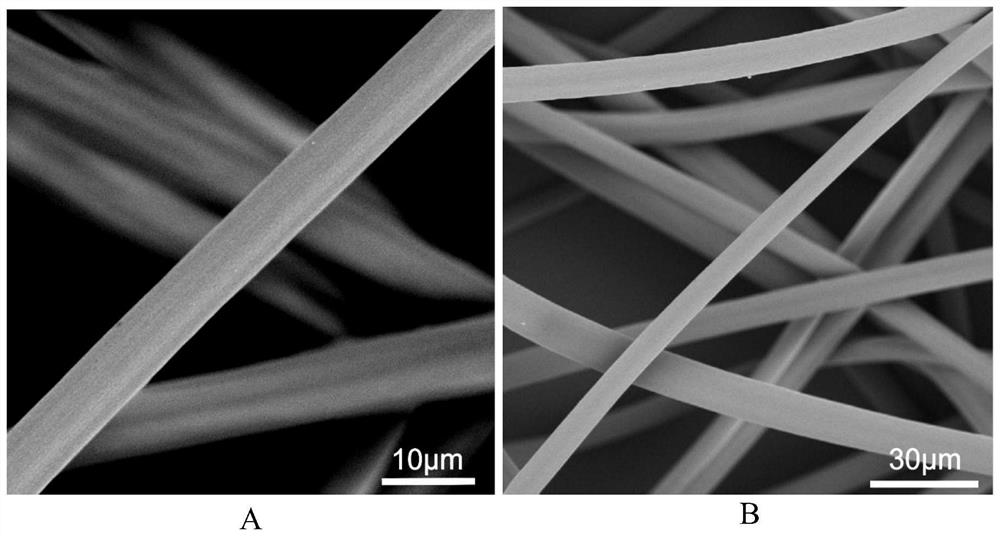

[0087] The electron micrograph of the water-soluble non-woven facial mask that embodiment 2 prepares is as figure 2 shown. from figure 2 with Figure 7 It can be seen from the figure that the diameter distribution of the ultrafine fibers of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com